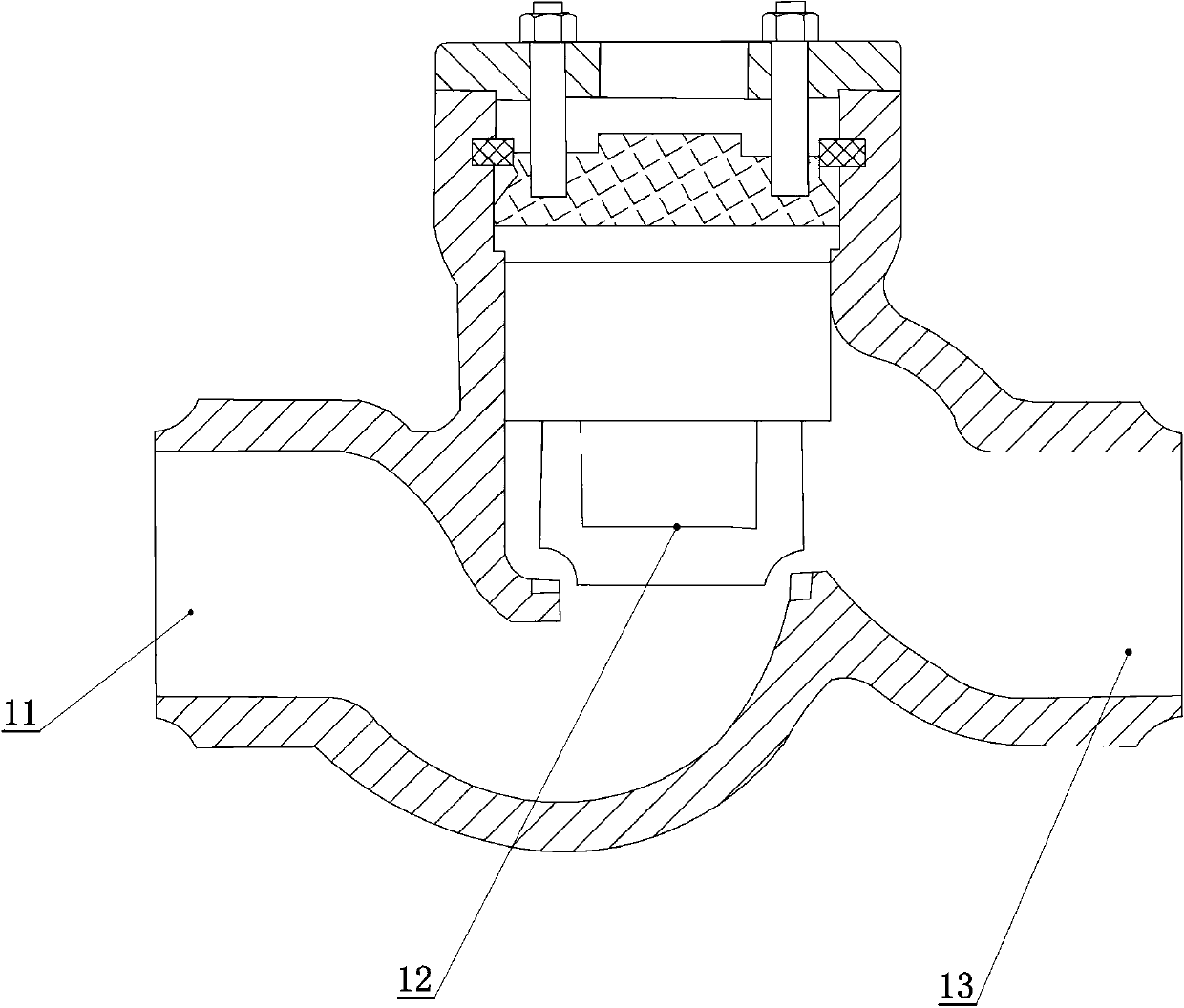

Black-flow preventer valve in pipeline

An anti-backflow and valve technology, applied in the direction of valves, etc., can solve the problems of affecting the thickness of the pipeline, no anti-backflow, and insufficient smooth flow of liquid or gas, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

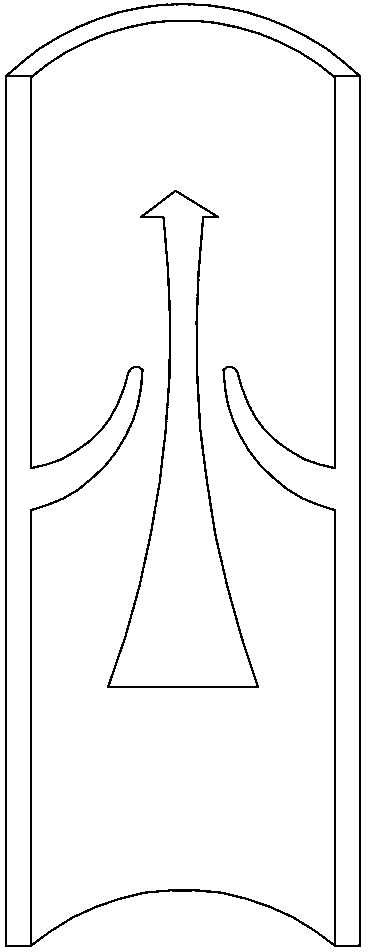

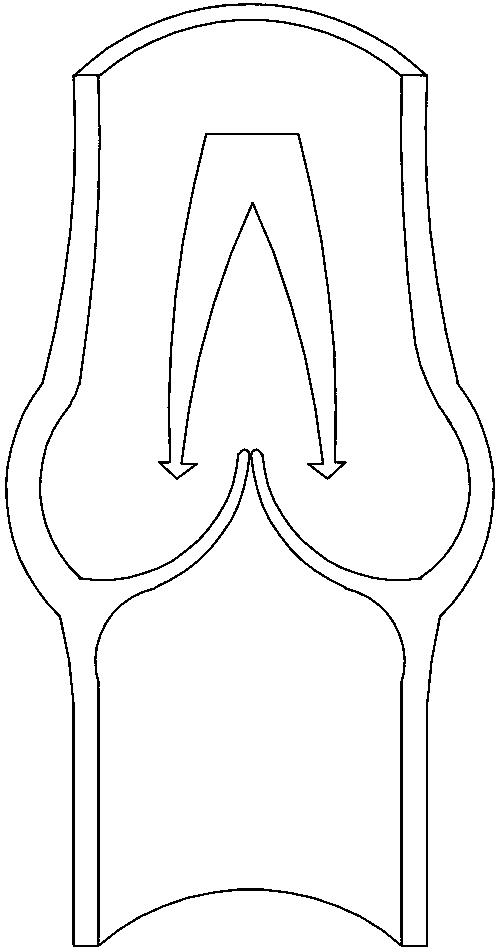

[0035] Such as Figure 6 As shown, the present invention sets two half-moon-shaped thin valves in the lumen just like the human vein valve, facing each other. The width in the middle of the valve is greater than the radius of the lumen, which is 1.5-2.5 times the radius of the lumen where it is located. The root of the valve is slightly Thick (convex sides) arcuate or semicircular ( Figure 6 ) is connected to the inner wall of the lumen to form a bag shape, and the two sides are connected to the opposite valve. Its free edge (concave edge) faces the flow direction to prevent the backflow of liquid or gas. elasticity and toughness. The lumen is transparent, and the two valves are set in eye-catching colors, which is easy to observe. It can be applied to various soft and hard pipes and various parts of the pipe. It has more advantages in medical applications. It can be used in infusion tubes, head, chest, abdomen and limbs. Various drainage tubes, inflatable masks, tracheal t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com