Jasmine tea and production method thereof

A technology for jasmine tea and jasmine flowers, which is applied in the direction of pre-extraction tea treatment and the like, can solve problems such as loss of aroma of tea base, contamination of tea base, and many broken products, so as to improve the intensity of aroma release, improve product quality, and enhance the quality of scented flowers. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] After the tea dregs are dried to a water content of 2.5wt%, and the flowers are cultivated under negative pressure of -10kPa until the opening degree of the jasmine flowers reaches 80%, the jasmine flowers and tea dregs are layered and tiled on adjacent mesh screens at a weight ratio of 0.6:1. 0.5cm. Control the vacuum degree of the box to -5kPa, the temperature at 34°C, and the relative humidity at 70RH%, until the tea absorbs fragrance and moisture until the water content is 7.5wt%, then the scenting is completed, the tea base is taken out, mixed evenly and packed into bags to obtain the finished jasmine tea.

Embodiment 2

[0037] After the tea dregs are dried to a water content of 3.0wt%, and the flowers are cultivated under a negative pressure of -20kPa until the opening degree of the jasmine flowers reaches 85%, the jasmine flowers and tea dregs are layered and tiled on adjacent mesh screens at a weight ratio of 0.8:1. 0.5cm. Control the vacuum degree of the box to -10kPa, temperature 36°C, relative humidity 80RH%, until the tea absorbs fragrance and moisture until the water content is 7.7wt%, then the scenting is over, take out the tea base, add dry jasmine petals at 1wt%, mix and pack The finished jasmine tea is obtained in a bag.

Embodiment 3

[0039] After the tea dregs are dried to a water content of 3.5wt%, and the flowers are cultivated under a negative pressure of -30kPa until the opening degree of the jasmine flowers reaches 85%, the jasmine flowers and tea dregs are layered and tiled on adjacent mesh screens at a weight ratio of 1:1. 0.5cm. Control the vacuum degree of the box to -15kPa, the temperature at 38°C, and the relative humidity at 85RH%, until the tea absorbs fragrance and moisture until the water content is 8.0wt%.

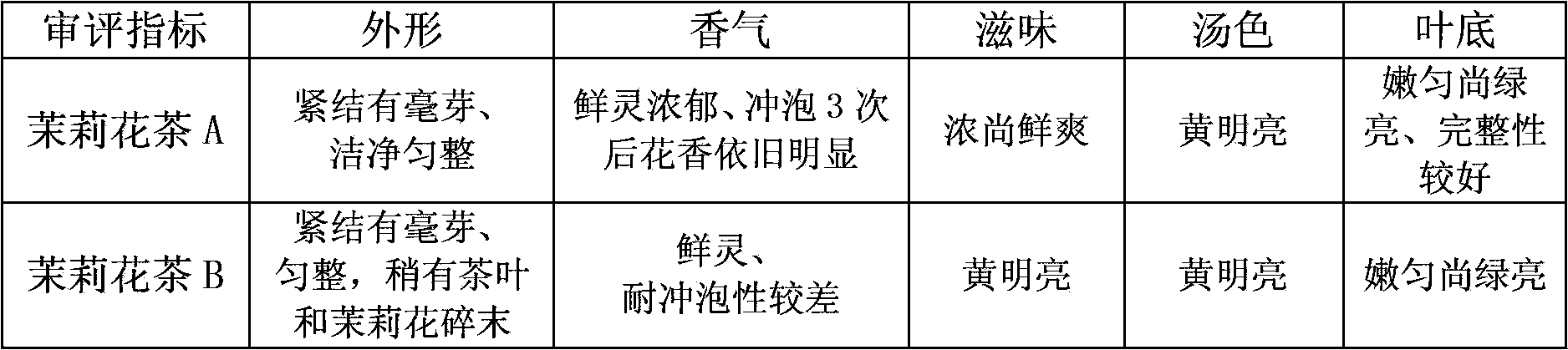

[0040] Through GC-MS detection and product review (Table 1 and Table 2), Examples 1 to 3 can effectively prevent jasmine flower pesticide residues from polluting scented tea products, and the produced scented tea products are clean and uniform in appearance, with a fresh and strong aroma. After brewing for 3 times, the flower fragrance is still obvious, the soup color is yellow and bright, and the leaf bottom is intact. It has obvious advantages over the comparative literature products...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com