Method for producing scintillator arrays with silver (ag) based gaps

A scintillator and gap technology, applied in the field of scintillators, can solve problems such as damage to glue and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

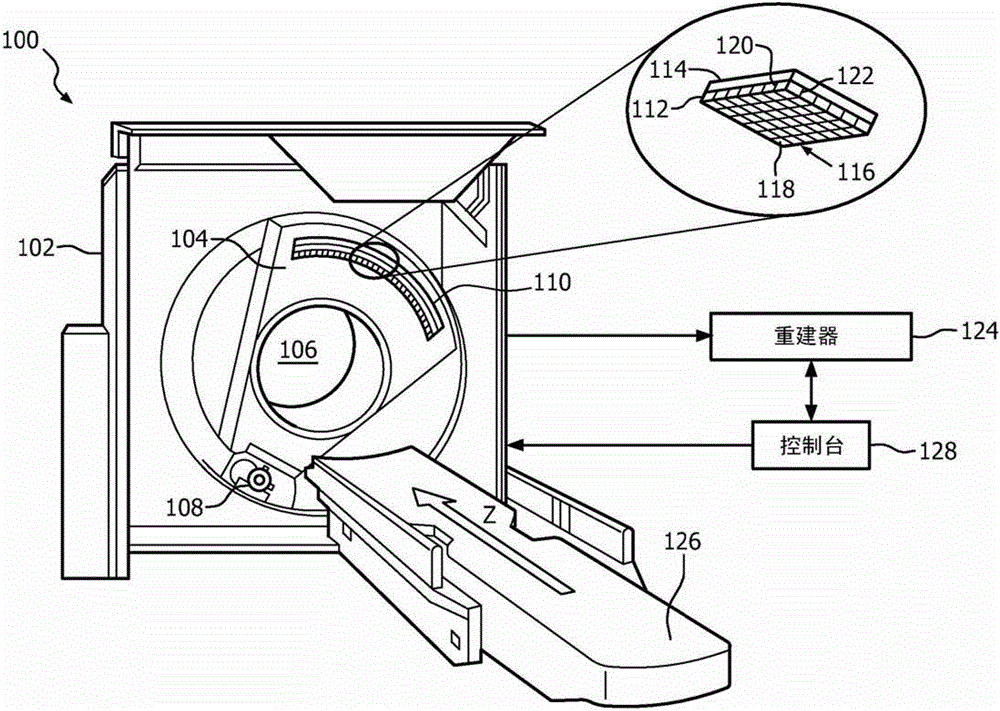

[0014] figure 1 An imaging system 100 is shown, such as a computed tomography (CT) system, including a stationary gantry portion 102 and a rotating gantry portion 104 . The rotating gantry section 104 is rotatably supported by the stationary gantry section 102 and is configured to rotate about an inspection region 106 about a longitudinal or z-axis. The rotating gantry section 104 supports an X-ray source 108 , such as an X-ray tube, which rotates with the rotating gantry section 104 about the examination region 106 and emits radiation that penetrates the examination region 106 .

[0015] The radiation sensitive detector array 110 includes a plurality of scintillator arrays 112 each optically coupled to a photosensor array 114 . Each scintillator array 112 detects radiation penetrating the examination region 106 and generates a light signal indicative of the detected radiation, while the photosensor array 114 receives the light and generates a signal indicative of the light a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com