Apparatus for controlling electric power steering apparatus

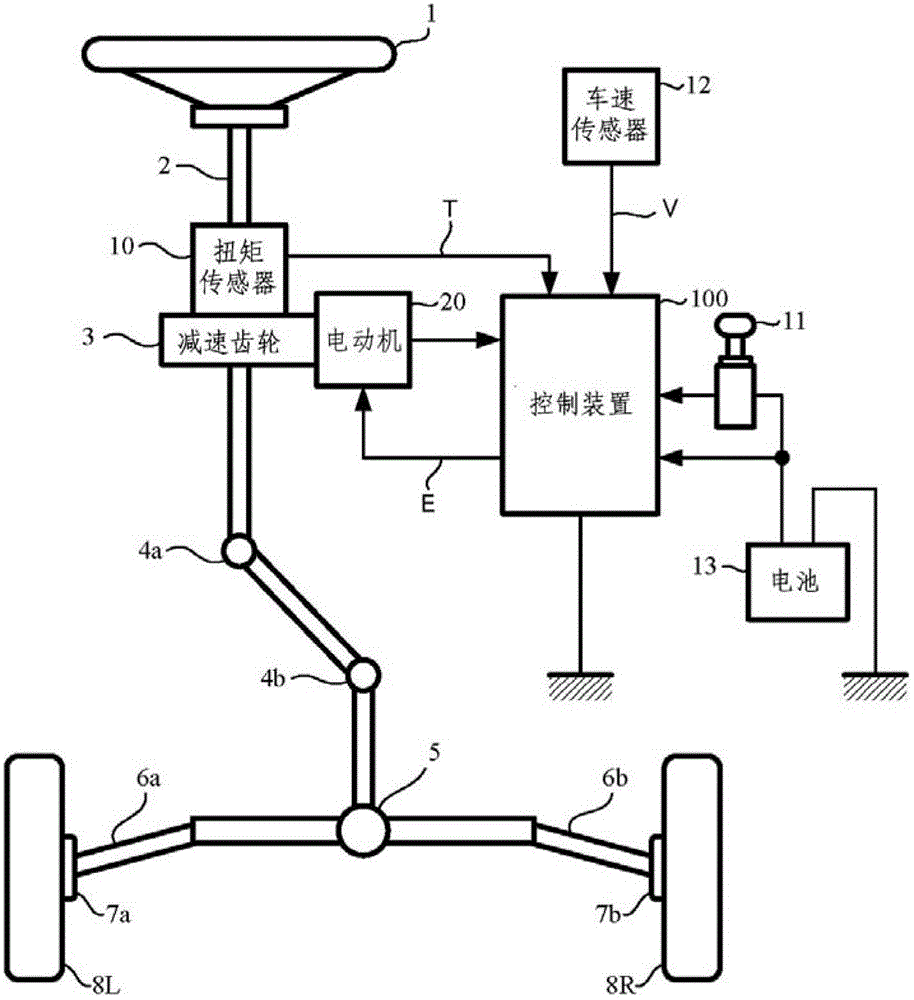

一种电动助力转向、控制装置的技术,应用在自动转向控制部件、电动转向机构、动力转向机构等方向,能够解决无法正确检测电流Im极性sign、很难正确测定电流Im极性等问题,达到高性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

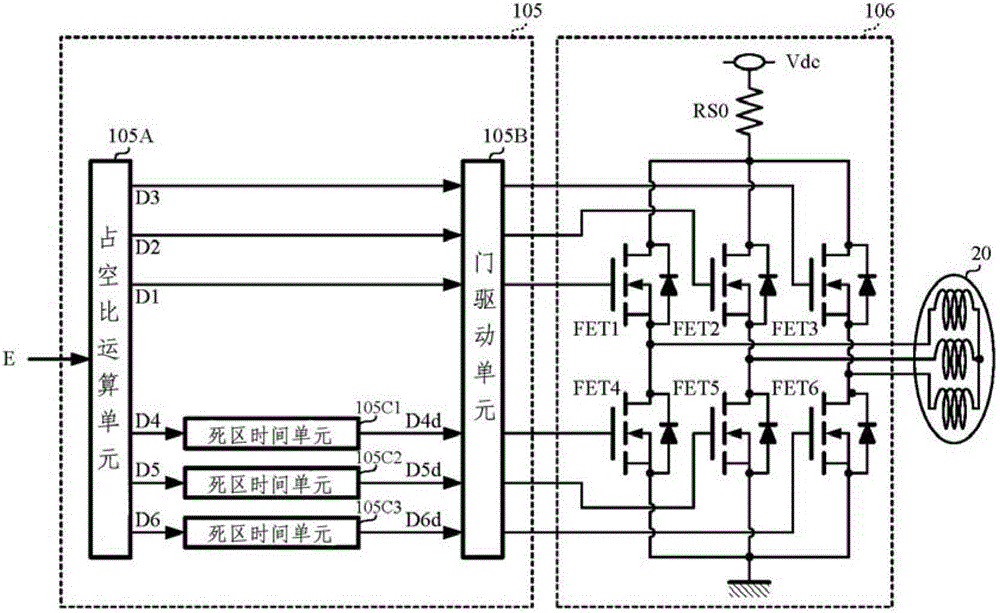

[0067] like Figure 5 As shown in (A), the dead time provided to prevent the passing current of the inverter composed of switching elements (FET, IGBT, triac, etc.) A characteristic distortion (dead zone DB) of the output current occurs. However, the dead zone (DB), in Figure 5 In (A), for example, at a low temperature (such as 0°C), when the temperature changes to a high temperature (such as 40°C), such as Figure 5 As shown in (B), it becomes narrow (dead zone DB'( Image 6 shown. That is, let the temperature of the converter (FET) be t, the temperature coefficient be C, and the dead zone width at 0°C be DB 0 , then the actual dead zone width DB is expressed by the following formula 6.

[0068] (Formula 6)

[0069] DB=-C·t+DB 0

[0070] Here, the dead time compensation is to apply a compensation voltage against the timing of crossing 0 ampere, eliminating such as Figure 5 The characteristic distortion (DB, DB') of the output current shown in (A) and (B). That is, u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com