Frequency mixing nonlinear ultrasonic detection method for structure microcracks based on bispectrum analysis

A technology of nonlinear ultrasonic and detection methods, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, and can solve problems such as inability to achieve positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with specific embodiment:

[0054] The implementation process of this embodiment includes the following steps:

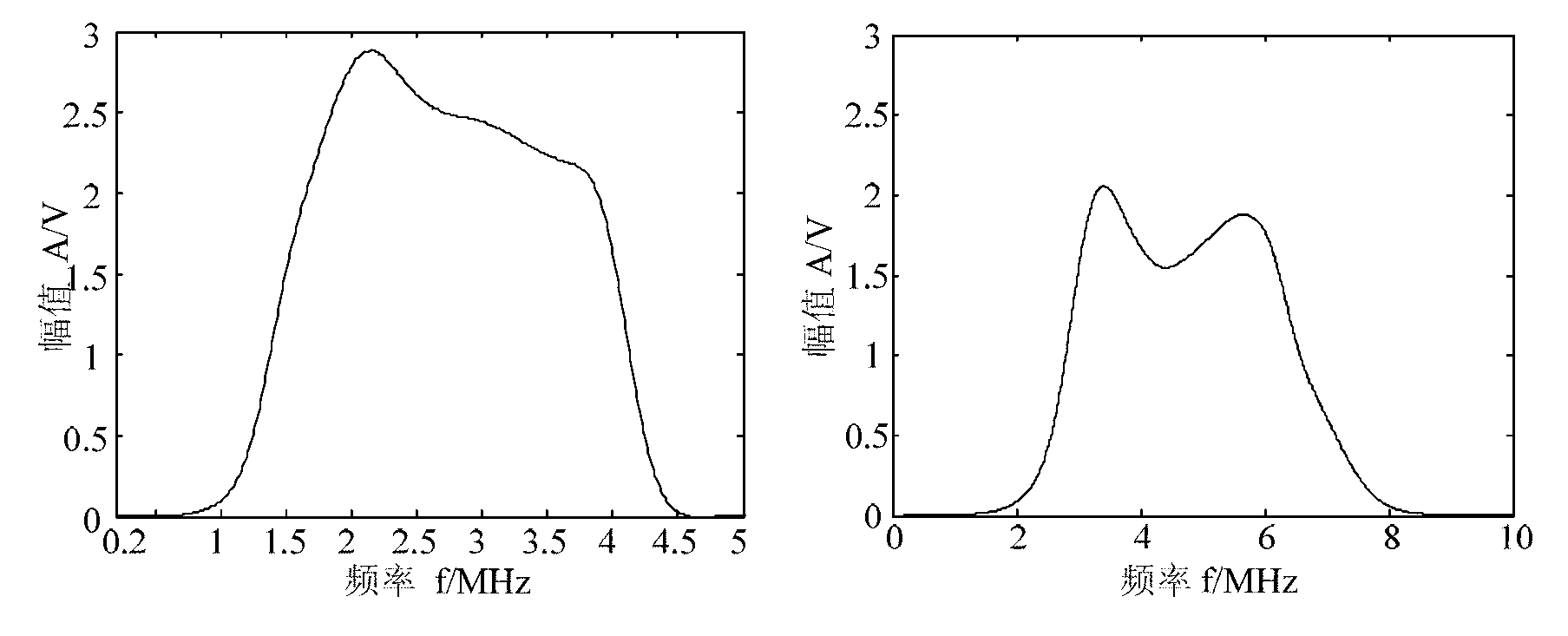

[0055] 1) According to the frequency response characteristics of the excitation probe (such as image 3 As shown in a), select the frequency 2MHz at the maximum frequency response amplitude as the excitation frequency of the excitation probe. Depending on the frequency response characteristics of the excitation / reception probe (eg image 3 As shown in b), determine that the frequency range of the excitation / reception probe is 2.05M-3.5MHz, so that the generated difference frequency and frequency signals are within the best response range of the excitation / reception probe.

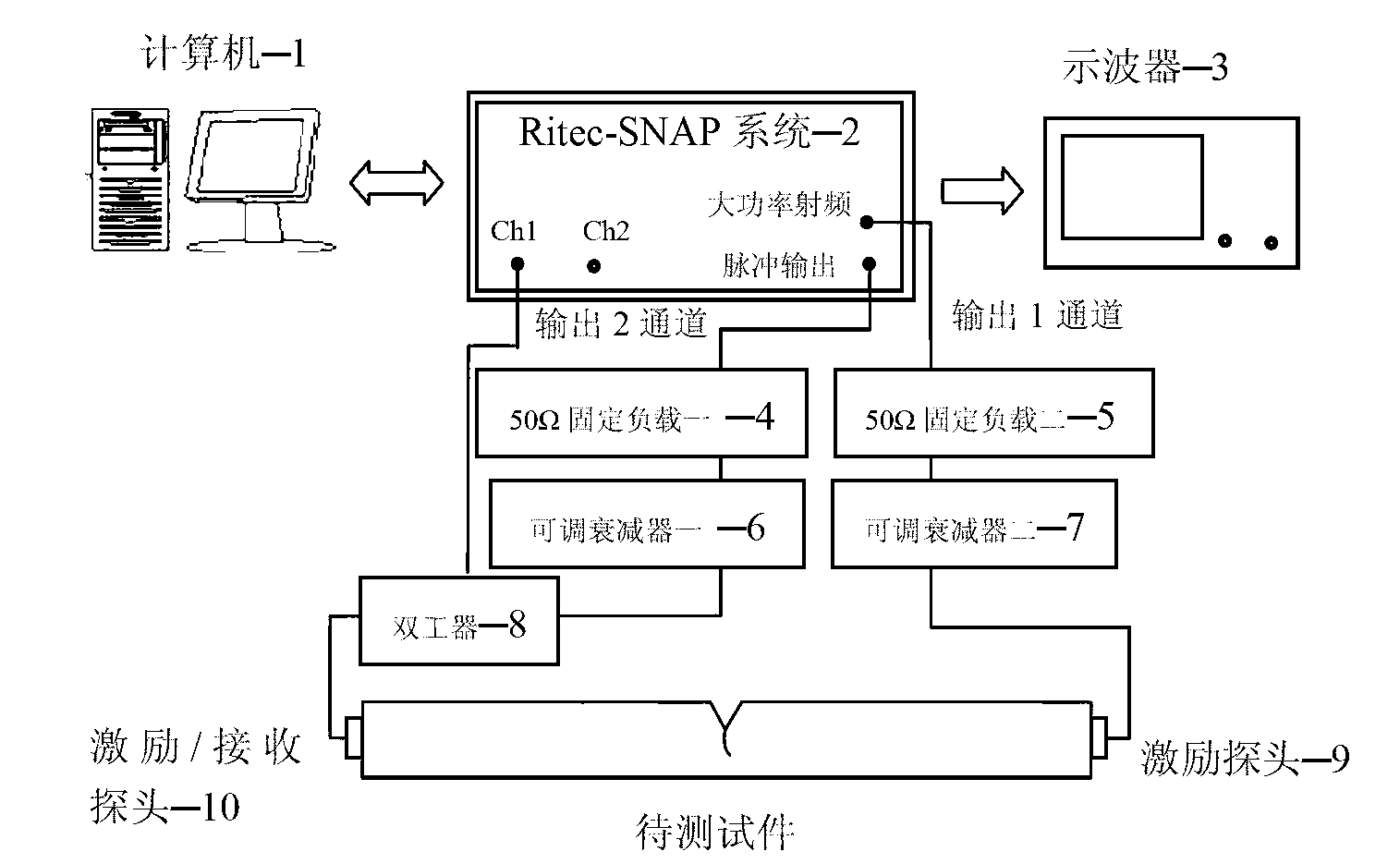

[0056] 2) Connect the instruments well, and place the two probes at both ends of the specimen. Set the excitation signal frequency of the excitation probe 9 to 2MHz, and change the excitation signal frequency of the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com