Voltage stabilizing test warehouse

A test chamber and chamber body technology, used in engine testing, machine/structural component testing, measuring devices, etc., can solve problems such as temperature instability, poor accuracy and stability, and inability to correctly evaluate the working state of the test piece. The effect of temperature and wind speed stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

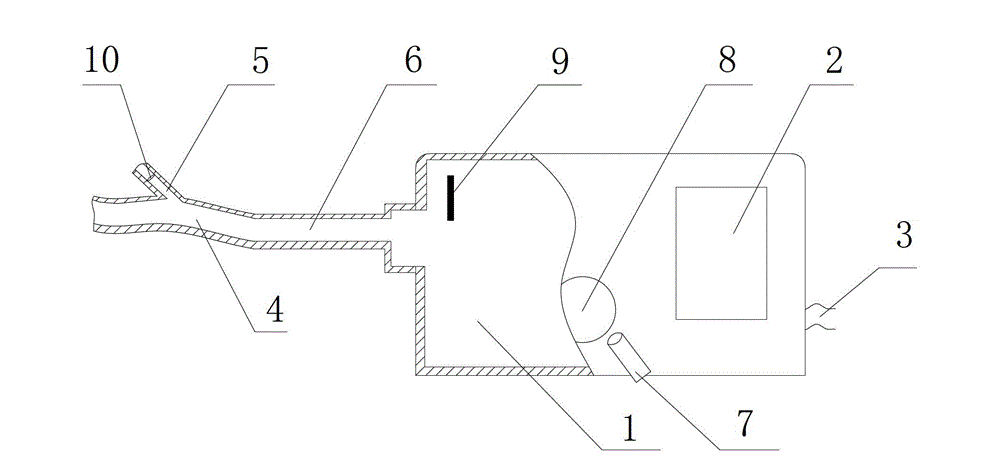

[0008] As shown in the figure, the test chamber includes a chamber body 1, an air induction section 4, and an exhaust air section 3. One end of the air induction section 4 is connected to the chamber body 1, and the other end is connected to the main regulating butterfly valve behind the expander. There is an air-inducing section 5 for stepless mixing of hot air in proportion, and a flow-stabilizing section 6 is set in the air-introducing section close to the warehouse body. The flow-stabilizing section 4 is a straight pipe whose diameter and length are matched in proportion to 3 to 8 times. , the bin body 1 is a sealed structure and is provided with a bin door 2, a temperature sensor 9 is arranged in the bin body 1, the temperature sensor is connected to a controller, and the controller is connected to a hot air valve 10, and a resistant valve is installed on both sides of the bin body A high-temperature glass observation window 8 is provided with a video monitoring system 7 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com