Solvent type matte wood lacquer and preparation method of same

A kind of wood paint and solvent-based technology, applied in the direction of polyester paint, coating, etc., can solve the problems of paint film wear resistance, poor hardness, insufficient paint and coating technology, and unsatisfactory coating effect. Achieve good gloss retention, easy mass production, and good decorative and protective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A kind of solvent type matt wood lacquer, this solvent type matt wood varnish comprises A component and B component, described A component comprises curing agent and thinner, and the weight ratio of described curing agent and thinner is 1: 1, by weight.

[0054] Described curing agent is made up of following components:

[0055]

[0056] The diluent consists of the following components:

[0057]

[0058] The described component B (main agent) consists of the following components:

[0059]

[0060] When used, the weight mixing ratio of component A and component B is 1:2.

[0061] The alkyd resin (A) is soybean oil short oil alkyd resin, which is 3106-X-70 from Shanghai Changxing Resin Co., Ltd.; the alkyd resin (B) is castor oil short oil alkyd resin (B) is 3401-XT-70 of Shanghai Changxing Resin Co., Ltd.; the described anti-settling agent is 6900-20X of Disparon; the described dispersant is EFKA-4010; the described solvent is made of xylene , butyl acetate ...

Embodiment 2

[0069] A kind of solvent type matt wood lacquer, this solvent type matt wood varnish comprises A component and B component, described A component comprises curing agent and thinner, and the weight ratio of described curing agent and thinner is 1: 1, by weight.

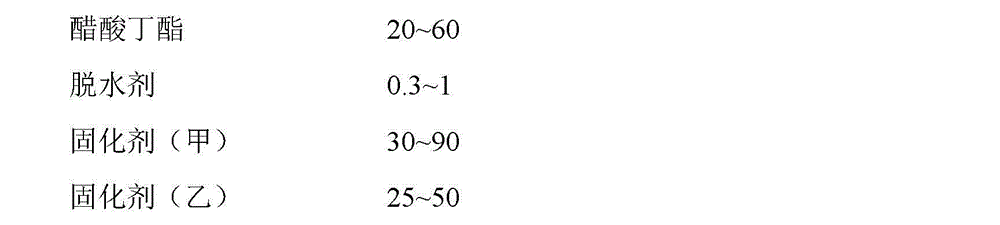

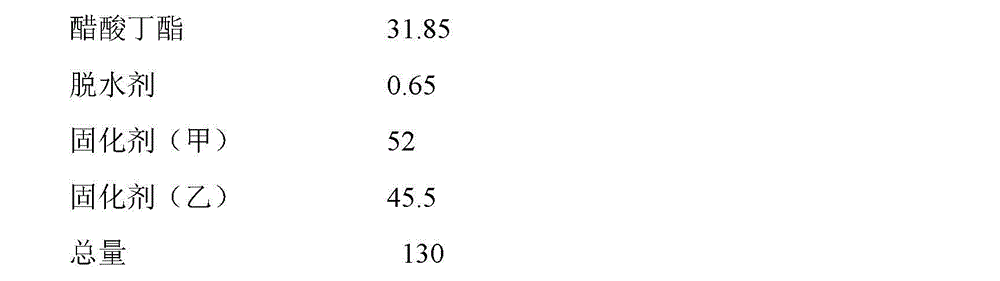

[0070] Described curing agent is made up of following components:

[0071]

[0072] The diluent consists of the following components:

[0073]

[0074]

[0075] The described component B (main agent) consists of the following components:

[0076]

[0077] When used, the weight mixing ratio of component A and component B is 1:2.

[0078] The alkyd resin (A) is soybean oil short oil alkyd resin, which is 3106-X-70 from Shanghai Changxing Resin Co., Ltd.; the alkyd resin (B) is castor oil short oil alkyd resin (B) is 3401-XT-70 of Shanghai Changxing Resin Co., Ltd.; the anti-settling agent is Disparon 6900-20X; the dispersant is BYK-163; the solvent is xylene , butyl acetate and propylene glycol methyl eth...

Embodiment 3

[0086] A kind of solvent type matt wood lacquer, this solvent type matt wood varnish comprises A component and B component, described A component comprises curing agent and thinner, and the weight ratio of described curing agent and thinner is 1: 1, by weight.

[0087] Described curing agent is made up of following components:

[0088]

[0089] The diluent consists of the following components:

[0090]

[0091] The described component B (main agent) consists of the following components:

[0092]

[0093]

[0094] When used, the weight mixing ratio of component A and component B is 1:2.

[0095] The alkyd resin (A) is soybean oil short oil alkyd resin, which is 3106-X-70 from Shanghai Changxing Resin Co., Ltd.; the alkyd resin (B) is castor oil short oil alkyd resin (B) is 3401-XT-70 of Shanghai Changxing Resin Co., Ltd.; the described anti-settling agent is 6900-20X of Disparon; the described dispersant is EFKA-4010; the described solvent is made of xylene , bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com