Method for preparing chlorpyrifos by clean technology

A chlorpyrifos and process technology, which is applied in the field of preparation of chlorpyrifos by a clean process, can solve the problems of increasing the difficulty of wastewater treatment, long process flow, and many reaction steps, and achieve environmentally friendly production costs, high reaction yield, and improved purity and yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

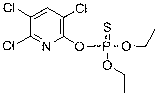

Image

Examples

Embodiment 1

[0023] To a 1000ml three-necked flask equipped with a thermometer and mechanical stirring, add 400g of a mixed solution of 3,5,6-trichloropyridin-2-alcohol sodium and water with a mass concentration of 15%, raise the temperature to 40°C and stir evenly, and then 0.8335 g of 4-dimethylaminopyridine, 0.7586 g of benzyltrimethylammonium chloride, 0.5036 g of 15-crown-5 and 45 ml of O,O-diethylphosphorylthiochloride were added. Add dropwise 30% Na after adding 2 CO 3 Keep the pH value of the solution at 8.5-11. After the pH is stable, raise the temperature to 55° C. and react for 1.5 hours. Stop stirring and let it stand at 60°C for 10 minutes, remove the water layer while it is hot, filter the organic phase with water, wash with water, and dry to obtain the finished product of chlorpyrifos. The content of HPLC analysis is 98.31%, and the yield is 98.12%.

Embodiment 2

[0025] To a 1000ml three-neck flask equipped with a thermometer and mechanical stirring, add 400g of a mixed solution of 3,5,6-trichloropyridin-2-alcohol sodium and water with a mass concentration of 15%, raise the temperature to 30°C and stir evenly, and then 0.8335 g of 4-dimethylaminopyridine, 0.7956 g of trioctylmethylammonium chloride, 0.5036 g of polyether P104 and 45 ml of O,O-diethylphosphorylthiochloride were added. After the addition, 30% KOH solution was added dropwise to maintain the pH value at 8.5-11. After the pH was stable, the temperature was raised to 50°C and reacted for 1.5 h. Stop stirring and let it stand at 60°C for 20 minutes, remove the water layer while it is hot, filter the organic phase with water, wash with water, and dry to obtain the crude product of chlorpyrifos. The content of HPLC analysis is 98.14%, and the yield is 98.03%.

Embodiment 3

[0027] To a 1000ml three-neck flask equipped with a thermometer and mechanical stirring, add 400g of a mixed solution of 3,5,6-trichloropyridin-2-alcohol sodium and water with a mass concentration of 15%, raise the temperature to 30°C and stir evenly, and then 0.8335 g of 4-dimethylaminopyridine, 0.6834 g of tetrabutylammonium chloride and 45 ml of O,O-diethylphosphorylthiochloride were added. After the addition, add 20% NaOH solution dropwise to maintain the pH value at 8.5-11. After the pH is stable, raise the temperature to 55°C and react for 2 hours. Stop stirring and let it stand at 55°C for 15 minutes, remove the water layer while it is hot, filter the organic phase with water, wash with water, and dry to obtain the crude product of chlorpyrifos, the content of HPLC analysis is 98.03%, and the yield is 98.00%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com