Mobile fermentation method for producing concentrated fertilizer through humic acid

A mobile fermentation and humic acid technology, applied in the direction of microbial-based methods, organic fertilizer preparation, biochemical equipment and methods, etc., can solve problems such as long composting time, low fertilizer efficiency, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

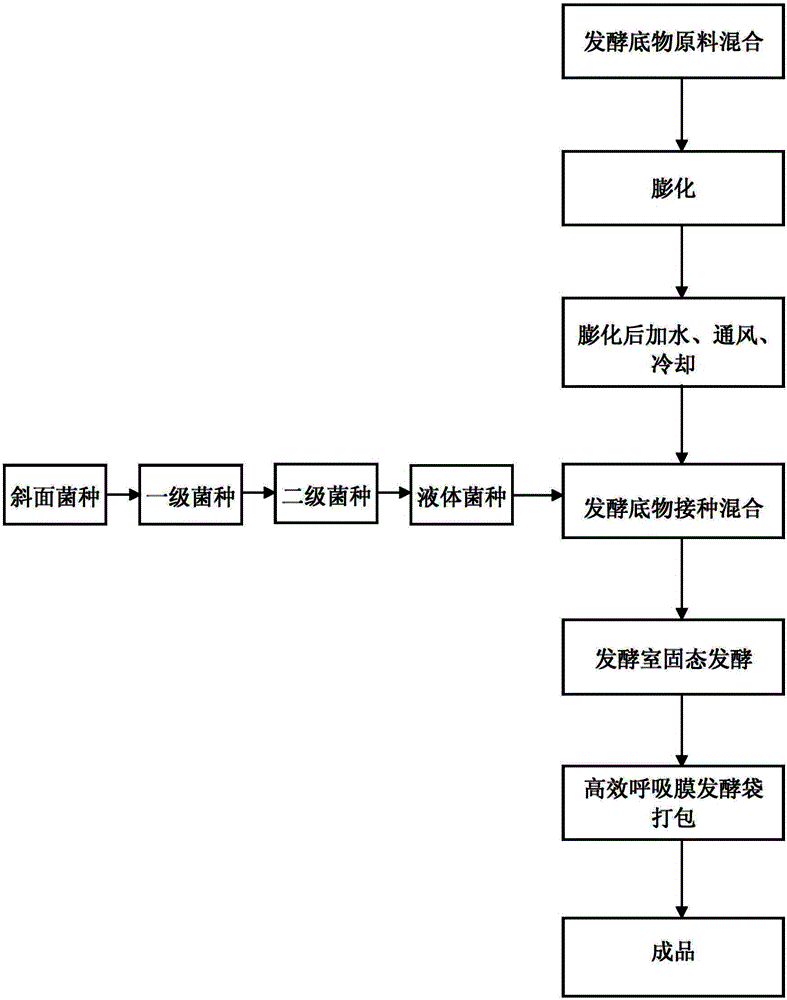

[0068] see figure 1 , prepare the high-efficiency fertilizer of the present embodiment according to the following method:

[0069] 1. Accurately weigh 600kg of fulvic acid, 100kg of distiller's grains, 100kg of corn straw powder, 100kg of urea, 20kg of diammonium hydrogen phosphate, 80kg of potassium chloride, and 200kg of yellow water, and mix them evenly to make a fermentation substrate. The moisture content of the fermentation substrate is 25 %.

[0070] 2. After the fermentation substrate is mixed, it is subjected to 0.4 MPa saturated steam through a twin-screw extrusion extruder at 150° C. for extrusion and expansion.

[0071] 3. After the fermentation substrate is puffed, it is transported to the wet material mixer, and then yellow water is added in proportion to continuous stirring and compressed air is introduced to reduce the temperature of the fermentation substrate to 35°C.

[0072] 4. Trichoderma harzianum, Cellulomonas hygroides, Bacillus lateralis, Bacillus...

Embodiment 2

[0116] see figure 1 , prepare the high-efficiency fertilizer of the present embodiment according to the following method:

[0117] 1. Accurately weigh 500kg of fulvic acid, 200kg of distiller's grains, 185kg of corn straw powder, 50kg of urea, 15kg of diammonium hydrogen phosphate, 50kg of potassium chloride, and 150kg of yellow water, and mix them evenly to make a fermentation substrate. The moisture content of the fermentation substrate is 25 %.

[0118] 2. After the fermentation substrate is mixed, it is subjected to 0.4 MPa saturated steam through a twin-screw extrusion extruder at 150° C. for extrusion and expansion.

[0119] 3. After the fermentation substrate is puffed, it is transported to the wet material mixer, and then yellow water is added in proportion to continuous stirring and compressed air is introduced to reduce the temperature of the fermentation substrate to 35°C.

[0120] 4. Trichoderma harzianum, Cellulomonas hygroides, Bacillus lateralis, Bacillus ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com