Cart running mechanism for bridge cranes

An overhead crane and operating mechanism technology, which is applied in the directions of traveling mechanism, transportation and packaging, load hanging components, etc., can solve the problems such as the transmission chain length of the traveling mechanism, the high rigidity requirement of the walking platform, and the easy failure. The effect of high installation accuracy, high work efficiency and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

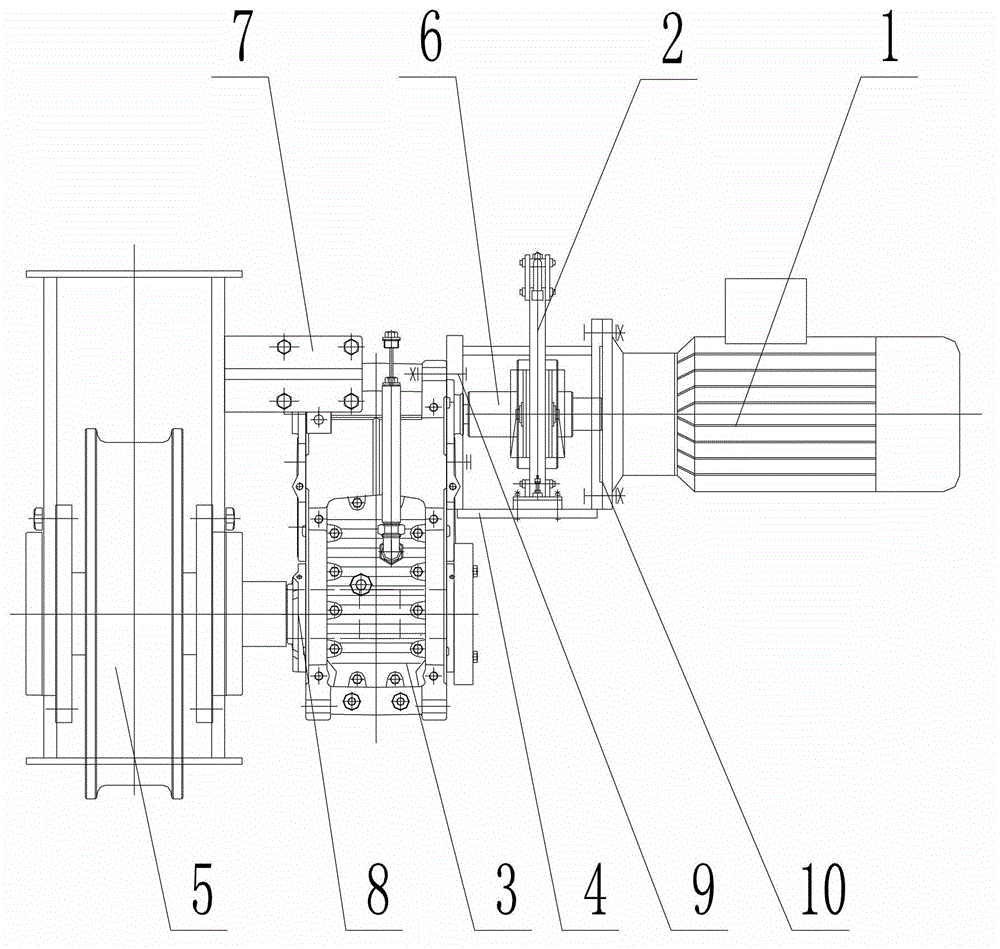

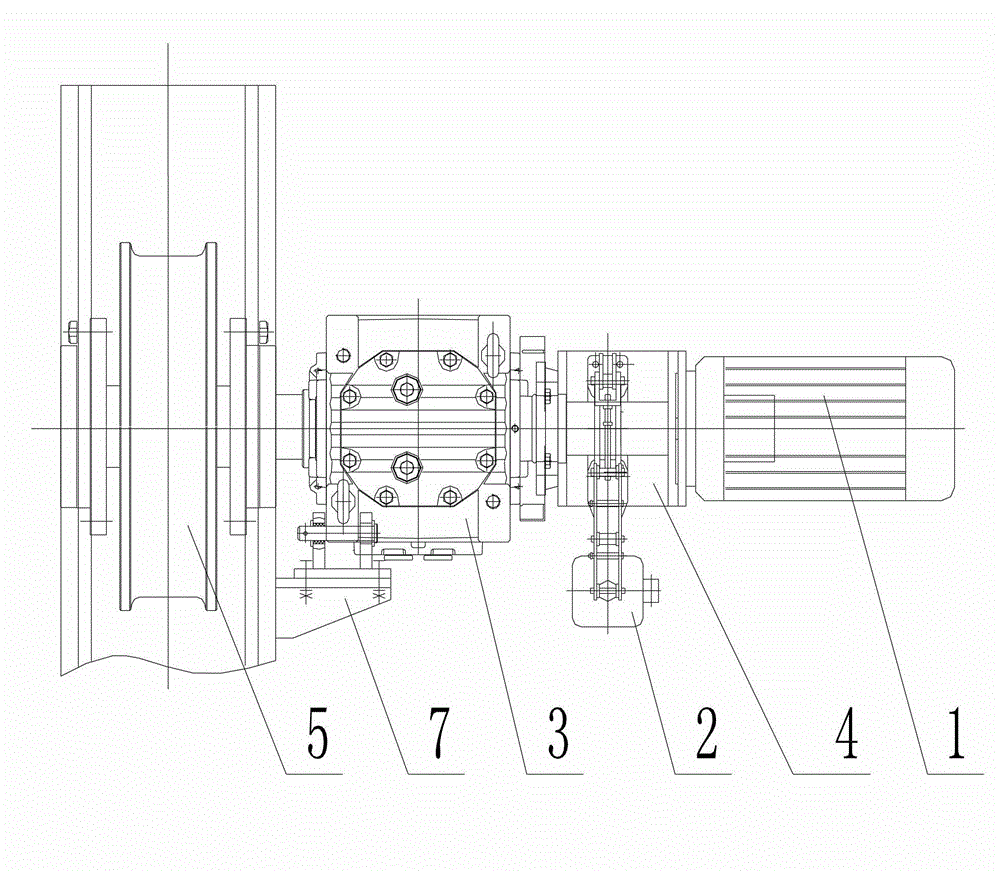

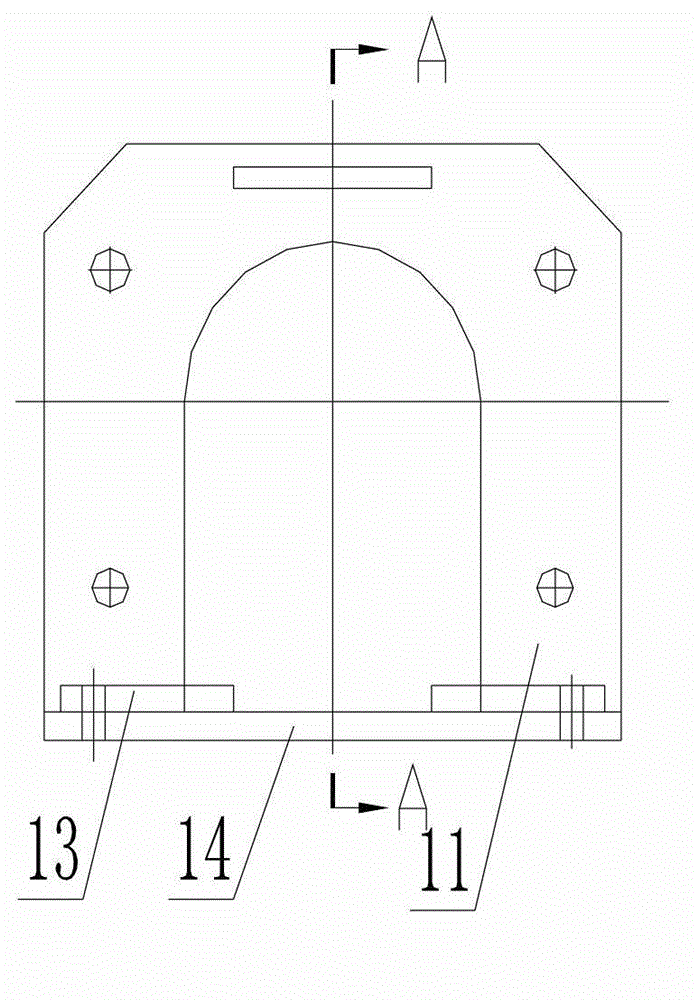

[0030] The specific embodiment of the present invention is shown in accompanying drawing, is made up of motor 1, brake 2, speed reducer 3, brake wheel coupling 6 and wheel set 5; It is characterized in that motor 1 and brake 2 are fixed by connecting frame 4 On the housing of the reducer 3, the brake wheel coupling 6 is placed in the connecting frame 4, the motor 1 is connected with the high-speed shaft of the reducer 3 through the brake wheel coupling 6, and the coaxiality is guaranteed; deceleration The low-speed output shaft of the device 3 is sleeved on the axle of the wheel group 5; one end of the moment arm 7 is mounted on the housing of the speed reducer 3, and the other end is mounted on the frame end beam of the wheel group 5 to play a fixing role.

[0031] The reducer 3 is a hollow flat key shaft vertical reducer, and its low-speed output shaft is a hollow flat key shaft 8. The hollow flat key shaft 8 is set on the shaft of the wheel group 5. The reducer 3 drives the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com