Synchronous feeding mechanism in feeding system of roller coating machine

A technology of feeding system and coating machine, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of harming human health, uneven spraying, and product quality cannot be effectively guaranteed, and achieves simple and ingenious structure and convenient transmission operation orderly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with specific drawings and embodiments.

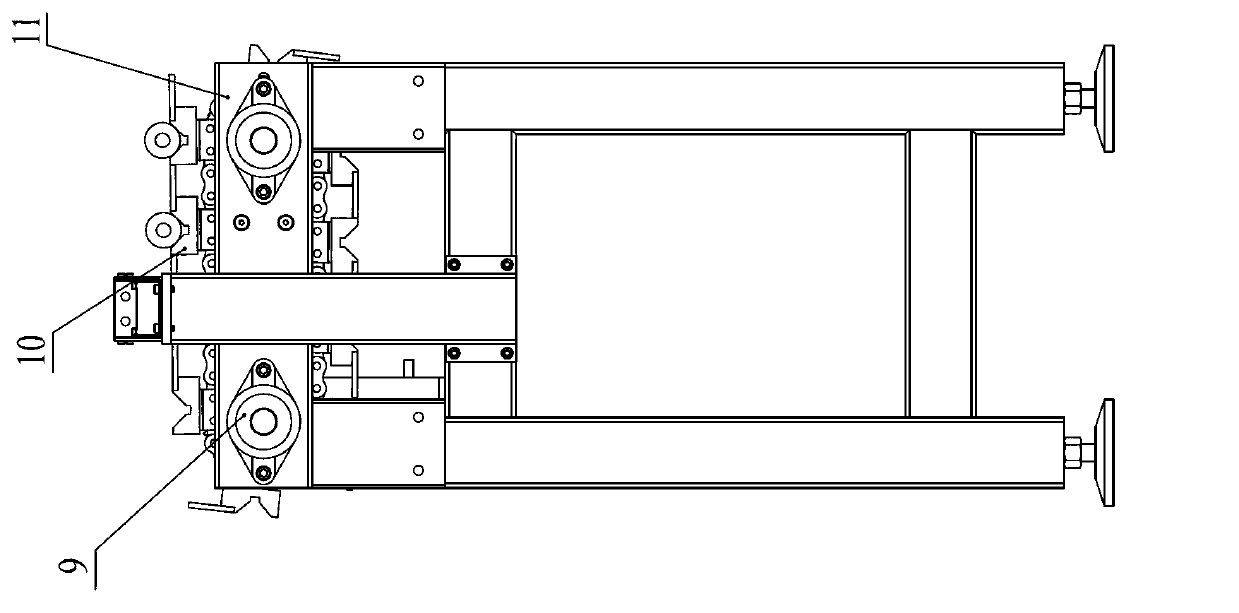

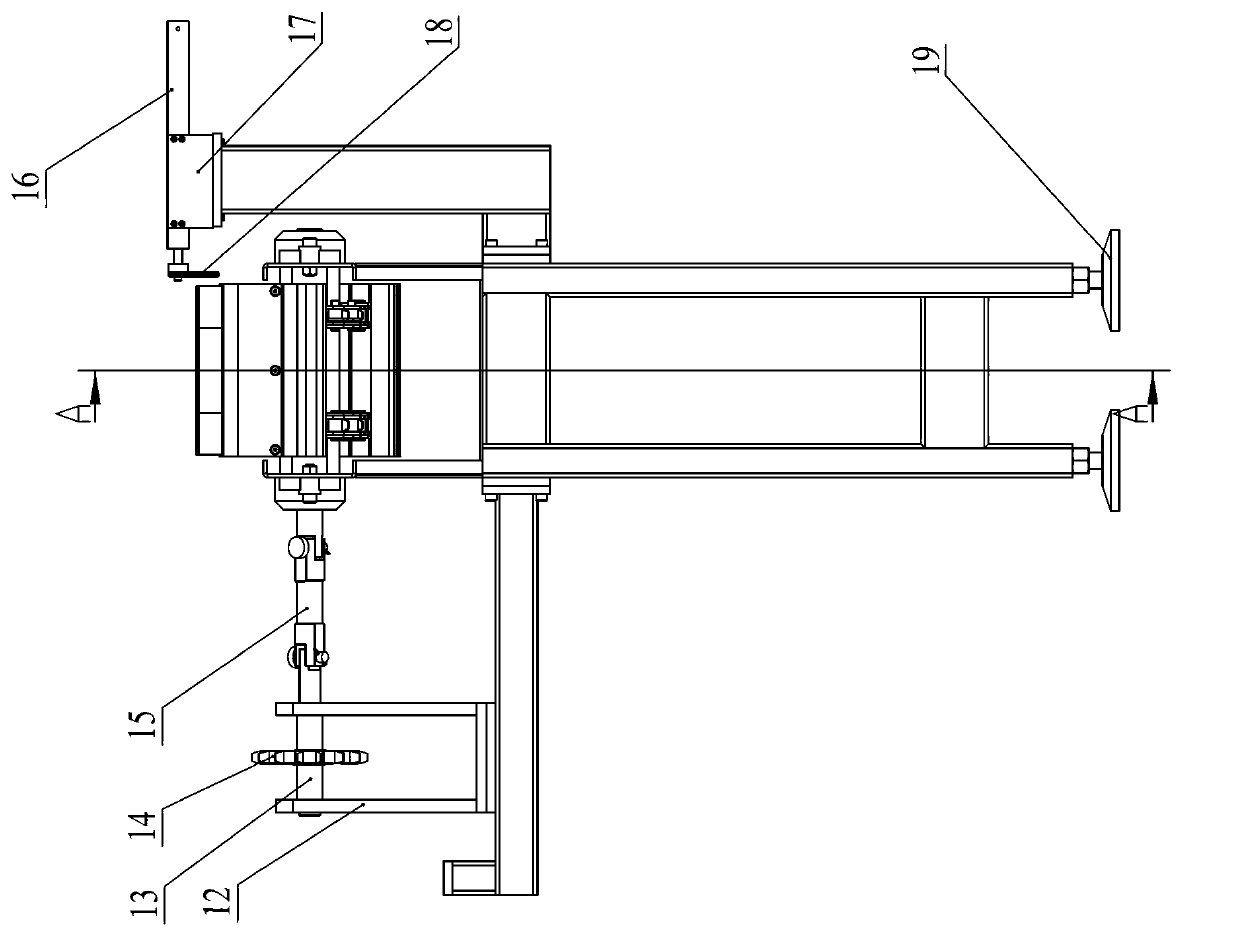

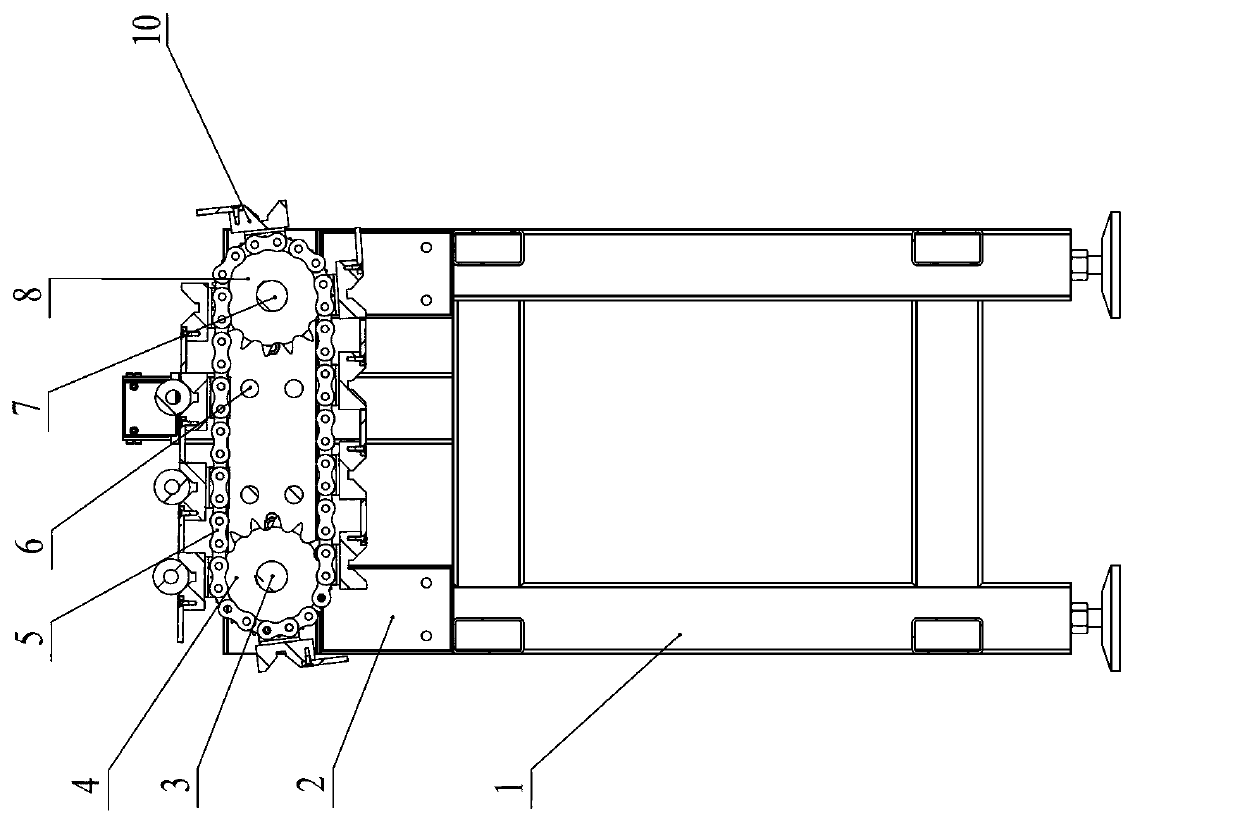

[0014] As shown in the figure: the synchronous feeding mechanism in the feeding system of the coating machine in the embodiment is mainly composed of a support base 1, a side plate support frame 2, a drive sprocket shaft 3, a drive sprocket 4, a chain 5, and a side plate connecting rod 6. Driven sprocket shaft 7, driven sprocket 8, bearing with seat 9, workpiece supporting plate 10, side plate 11, transmission bracket 12, power input shaft 13, input sprocket 14, connecting shaft 15, push cylinder 16 , cylinder mounting seat 17 and pusher plate 18 and other components.

[0015] Such as Figure 1~Figure 4 As shown, two side plates 11 are installed on the side plate support frame 2, and the two side plate support frames 11 are connected by side plate connecting rods 6, and the side plate support frame 2 is installed on the support base 1 through a lifting adjustm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com