Mobile vertical gas-electric vertical welding special equipment based on three-dimensional adjustment device

A technology of vertical gas-electric vertical welding and three-dimensional adjustment, which can be used in arc welding equipment, welding equipment, metal processing equipment, etc., and can solve problems such as increased construction costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

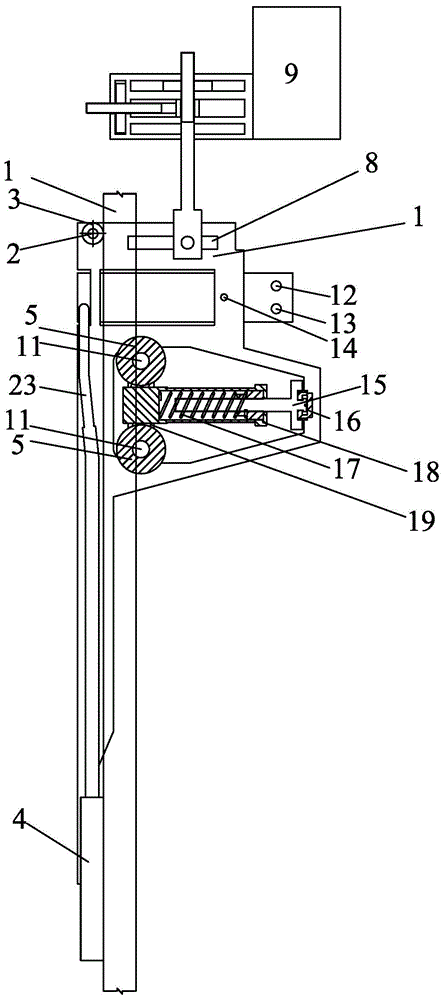

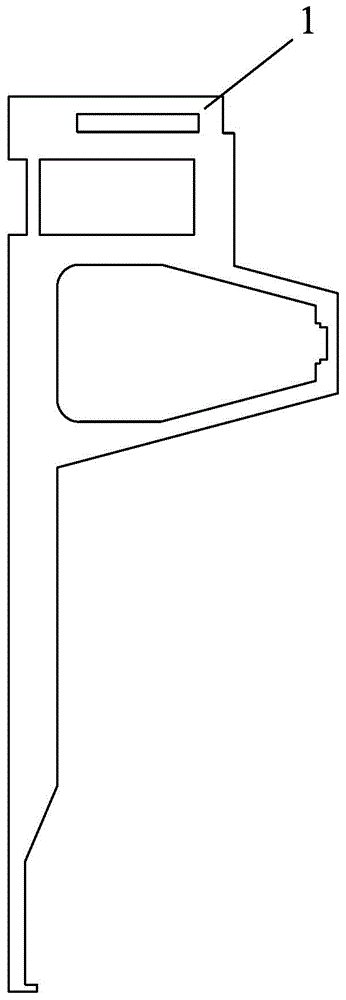

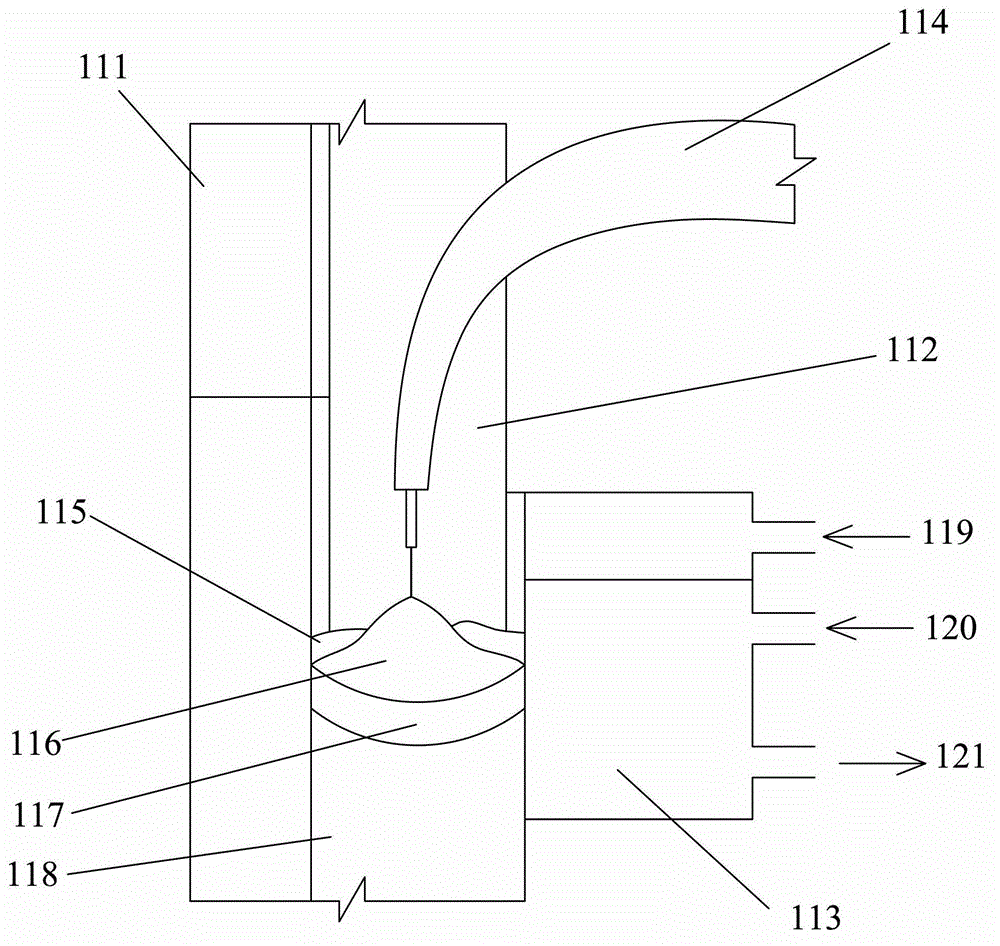

[0047] Such as figure 2 and image 3 As shown, the special equipment for vertical gas-electric vertical welding includes a plate-shaped frame body 1, and the plate-shaped frame body 1 is divided into the straight edge side (left side in the figure) located at the back of the plate to be welded and the plate-shaped frame body 1 located at the back of the plate to be welded. There are two parts on the special-shaped side (right side in the picture) of the front front. Wherein the support body upper part of straight side side perforates wheel axle 2 to set positioning wheel 3 after; Correspondingly, the back slider 4 is provided with a hole structure for hooking with the hook structure of the plate-shaped frame body, and also provided with a trapezoidal groove for realizing forced forming of the weld seam.

[0048] The front end faces of the positioning wheel 3 and the back slider 4 are in a plane, and are used to fit the back side of the steel plate 10 to be welded; There ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com