Hook with double hook bodies and suspension bracket

A hook-body, integrated technology, applied in hooks, hangers, clothing and other directions, can solve the problems of high production cost and complex production process, and achieve the effect of low production cost and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

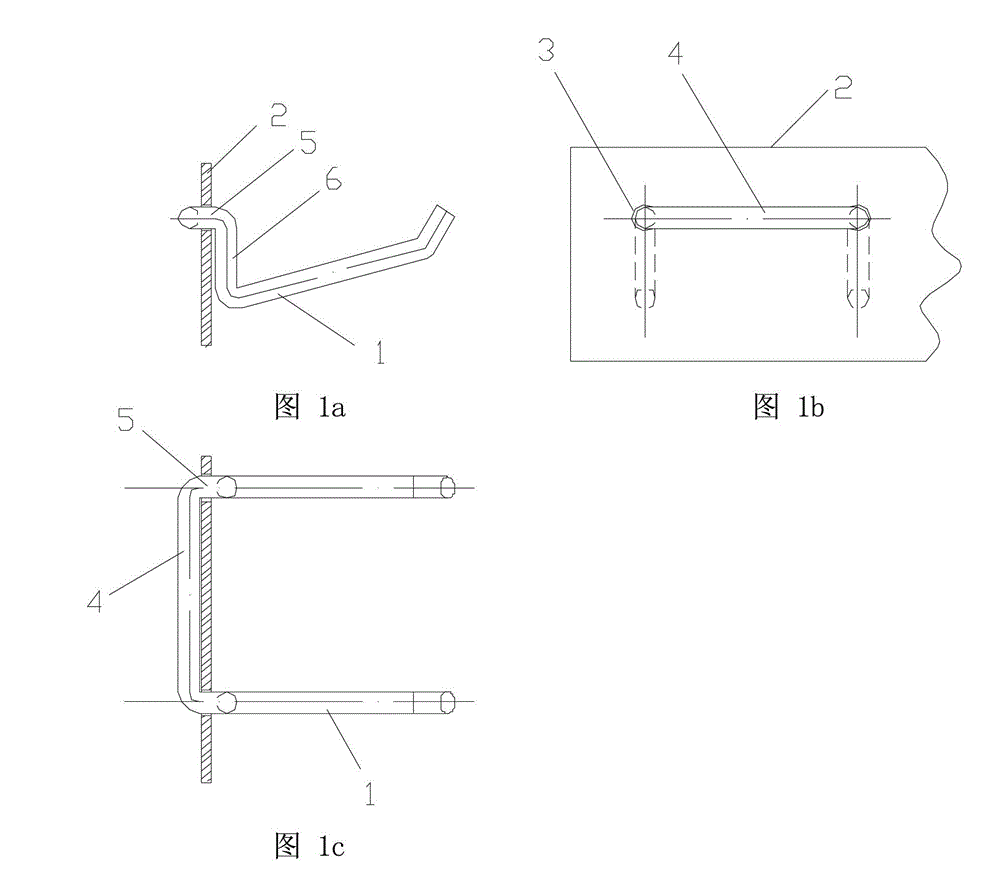

Embodiment 1

[0036] see figure 1 , the double-hook body hook of this embodiment includes two hook bodies 1 and two passing parts 5 passing through the hanging holes 3 of the hanging wall 2 during use, wherein the two passing parts 5 are arranged horizontally, and their length is slightly longer than that of the hanging wall 2 The length of the hanging hole 3 on the top, one of the two crossing parts 5 is bent and extended vertically downwards to form two hook arms 6, and the two hook bodies 1 are respectively connected to one of the hook arms 6; The other ends of the two passing parts 5 are connected into one body through a connecting rod, which is a horizontal bar 4; the bottom of the hook body 1 is inclined, so that an acute angle is formed between the bottom and the hook arm 6, The end of the hook body 1 is tilted upwards, and an obtuse angle is formed between the end and the bottom of the hook body 1. When hanging items, the hung items will naturally slide down to the corner between th...

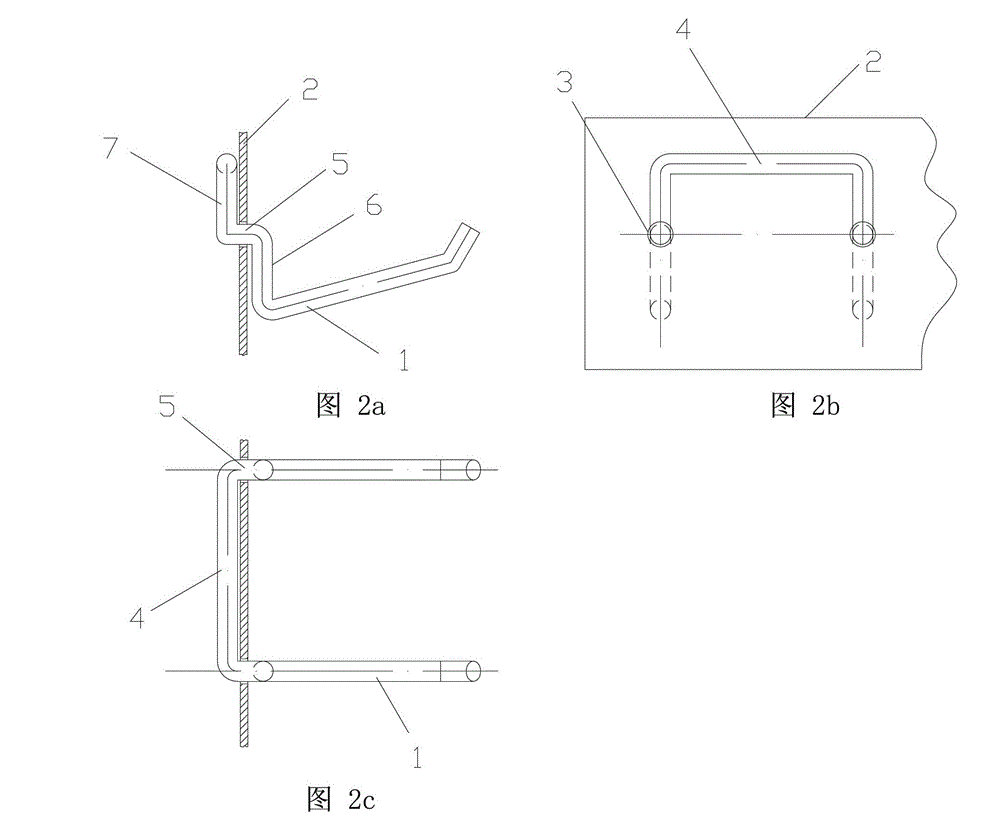

Embodiment 2

[0039] see figure 2The difference between this embodiment and Embodiment 1 is that in this embodiment, the crossing portion 5 has an extension arm 7 extending vertically upward at one end connected to the connecting rod, and the end of the extension arm 7 passes through a The cross bar 4 is connected as a whole; when the article is hung on the hook body 1, the surfaces of the extension arm 7 and the cross bar 4 are all in contact with the hanging wall 2 and generate an active force. Compared with the embodiment 1, the contact range is increased and the improvement The force is reduced, and the service life of the hook is extended.

[0040] Embodiments other than the above in this embodiment are the same as in Embodiment 1.

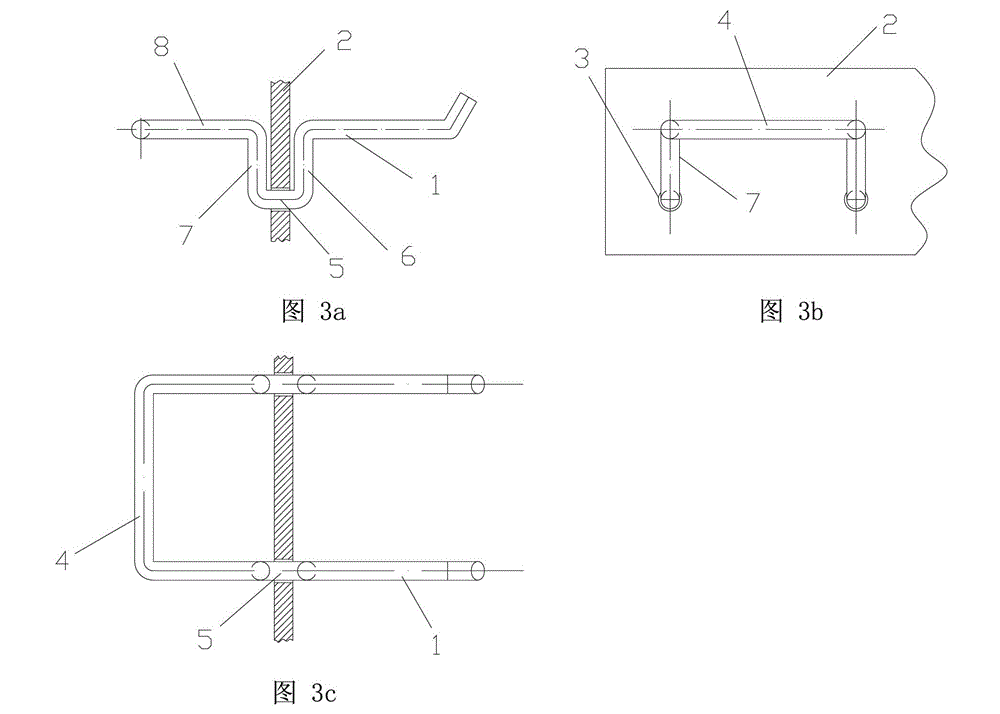

Embodiment 3

[0042] see image 3 The difference between this embodiment and Embodiment 2 is that in this embodiment, the hook arm 6 is formed by bending and extending vertically upward from one end of the crossing portion 5; the bottom of the hook body 1 is horizontal ; The end of the extension arm 7 is bent and extended in the horizontal direction to form a horizontal arm 8 , and the end of the horizontal arm 8 is connected as a whole by a cross bar 4 . In this embodiment, there is a certain distance between the crossbar 4 and the hanging wall 2, so the crossbar 4 can also be used for hanging articles, which increases the space for use of the hook.

[0043] Other implementations of this embodiment other than those described above can be implemented with reference to Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com