Rotor core

A technology of yoke and magnetic rotor, which is applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, electric components, etc., to achieve the effect of reducing material consumption and improving material yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

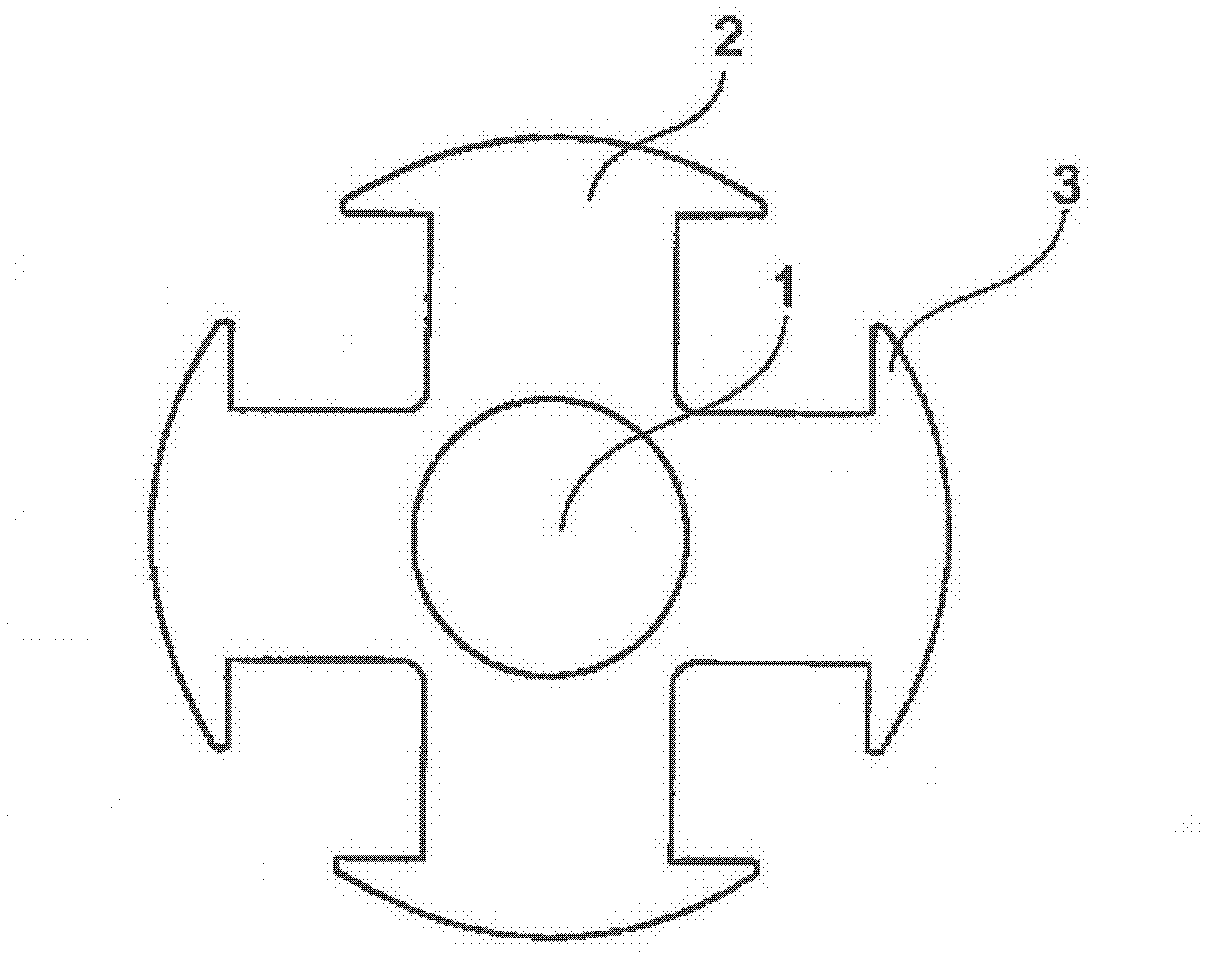

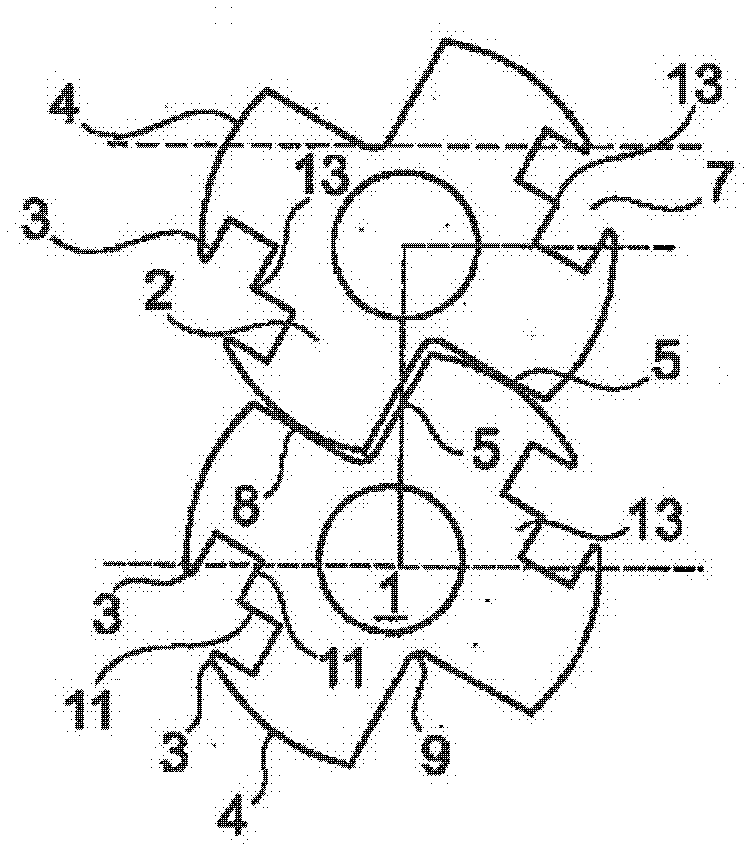

[0029] A rotor yoke frame according to the present invention, such as Figure 7 , comprising a stack of assembled magnetic plates 4, one of which is shown separately in Figure 4 middle.

[0030] According to a preferred exemplary implementation of the invention, each plate 4 has a plurality of magnetic poles, each magnetic pole has a single pole tip 3, on the side opposite to the pole tip 3, this magnetic pole has a pole extending to the A straight edge 5 of the radially outer circumference 6 of the pole.

[0031] Two adjacent poles have their pole tips 3 pointing towards the same interpole space 7 , while the edges 5 without pole tips delimit a further interpole space 8 . In the example shown with four poles, one plate 4 has two diametrically opposite interpole spaces 7 and two further diametrically opposite interpole spaces 8 .

[0032] These straight edges 5 meet adjacent to the hole 1, while on the side where the pole tip 3 is present, the pole body is widened so as to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com