Method for determining reasonable compacting temperature of modified asphalt mixture

A technology for asphalt mixture and modified asphalt, which is applied in the field of determining the reasonable compaction temperature of modified asphalt mixture and determining the compaction temperature, which can solve the problem that the shear rate asphalt is sensitive to changes in viscosity, and the assumed density/porosity standard is difficult to determine. , unsuitable construction state and other problems, to achieve the effect of rapid operation, shortened test period, and simple control of test conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

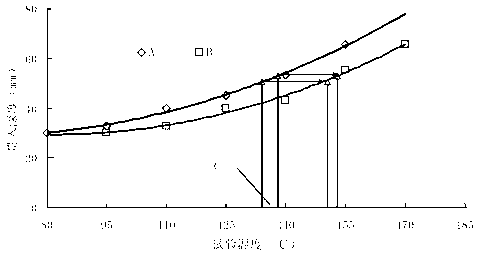

[0031] 1. Using a No. 90 base petroleum asphalt, according to the T0625-2011 method in the "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering" (JTG E-20-2011), the high-temperature viscosities at 135°C and 175°C are respectively 0.301Pa .s and 0.109Pa.s, and draw the viscosity-temperature curve; according to the provisions of Table 5.2.2-1 in "Technical Specifications for Construction of Highway Asphalt Pavement" (JTG F40-2004), the viscosity-temperature curve is drawn from 0.28±0.3Pa.s The reasonable compaction temperature range found on the Internet is 134~138°C;

[0032] 2. Determine the gradation of a continuous dense AC-13 asphalt mixture within the gradation range in Table 5.3.2-2 of "Technical Specifications for Construction of Highway Asphalt Pavement" (JTG F40-2004), as shown in Table 1, and select the amount of asphalt based on experience was 5.2%.

[0033] Table 1 AC-13 Grading Range

[0034]

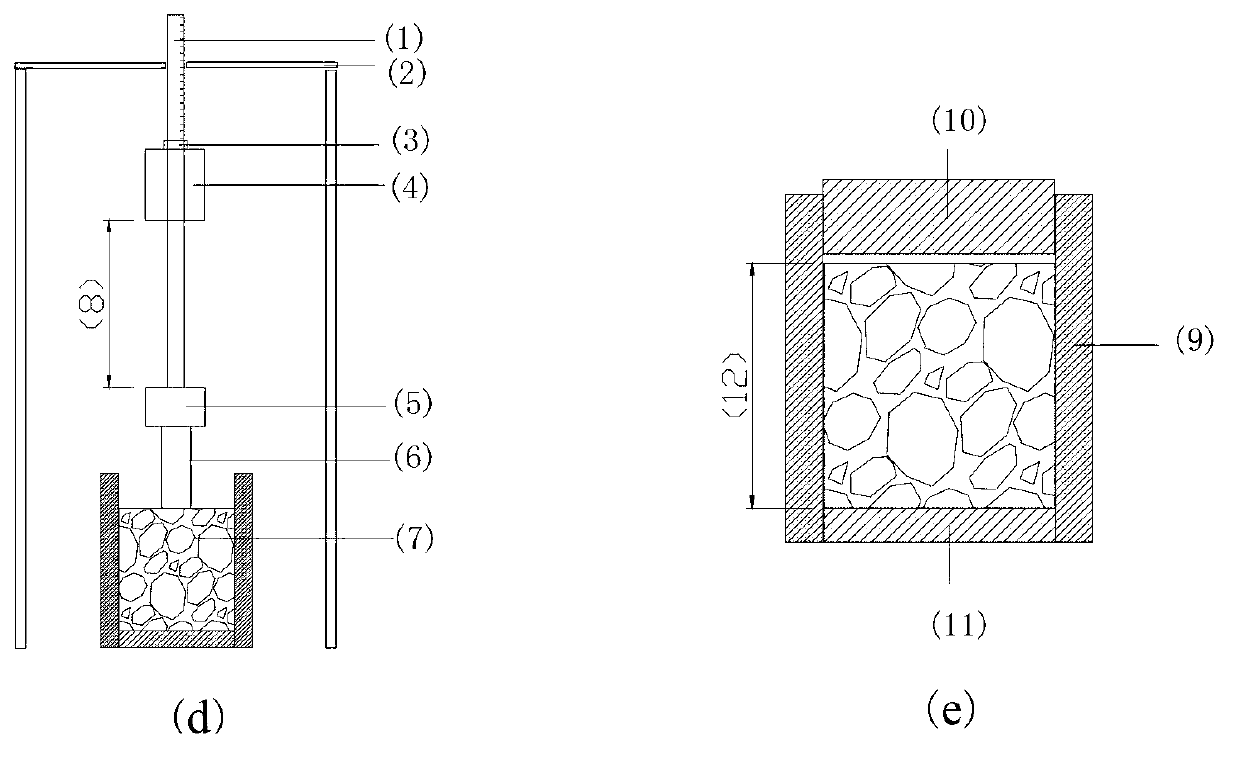

[0035] 3. Aggregate is prepared by step-by-s...

Embodiment 2

[0048] 1. Using a No. 70 base petroleum asphalt, according to the T0625-2011 method in the "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering" (JTG E-20-2011), the high-temperature viscosities at 135°C and 175°C are respectively 0.367Pa .s and 0.0775Pa.s and draw the viscosity-temperature curve; according to the provisions of Table 5.2.2-1 in "Technical Specifications for Construction of Highway Asphalt Pavement" (JTG F40-2004), from 0.28±0.3Pa.s on the viscosity-temperature curve It is found that the reasonable compaction temperature range is 140~144°C;

[0049] 2. Determine the gradation of a continuous dense AC-16 asphalt mixture within the gradation range in Table 5.3.2-2 of "Technical Specifications for Construction of Highway Asphalt Pavement" (JTG F40-2004), as shown in Table 4, and select the amount of asphalt based on experience 5.0%.

[0050] Table 4 AC-16 grading range

[0051]

[0052] 3. The rest of the test steps are exactly the same a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com