System for measuring longitudinal wave thickness of pulse laser

A technology of thickness measurement and pulsed laser, which is applied in the direction of measuring devices, using ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems that reflected sound pulse energy is difficult to be detected, reduces measurement accuracy, and limits the scope of application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

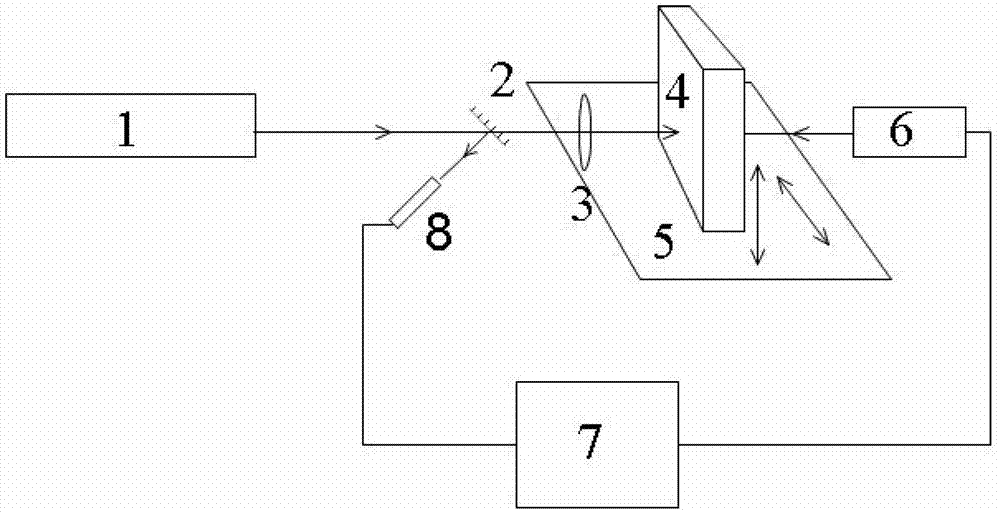

[0006] The concrete structure of the present invention is provided by following accompanying drawing and embodiment.

[0007] Pulse laser body longitudinal wave thickness measurement system, which includes pulse laser 1, laser interferometer 6, beam splitter 2, convex lens 3, photodiode 8 and computer 7, beam splitter 2 and convex lens 3 are arranged on the same optical path in turn, photodiode 8 Receive the reflected light of the beam splitter 2 on the reflected light path of the beam splitter 2, and the electric signal it outputs is connected with the receiving end of the signal acquisition card on the electronic computer 7, and the other receiving end of the signal acquisition card is connected with the output end of the laser interferometer 6 Connected, the present invention is characterized in that the laser light emitted by the pulse laser 1 is focused by the convex lens 3, and a high-frequency ultrasonic body longitudinal wave is excited on one side of the sample 4 to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com