Universal vacuum chuck with automatic closing function

A vacuum suction cup and self-shutoff technology, applied in the direction of suction cups, connecting components, mechanical equipment, etc., can solve the problems of high cost and complex system, and achieve the effects of flexible and convenient use, simple equipment structure and high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

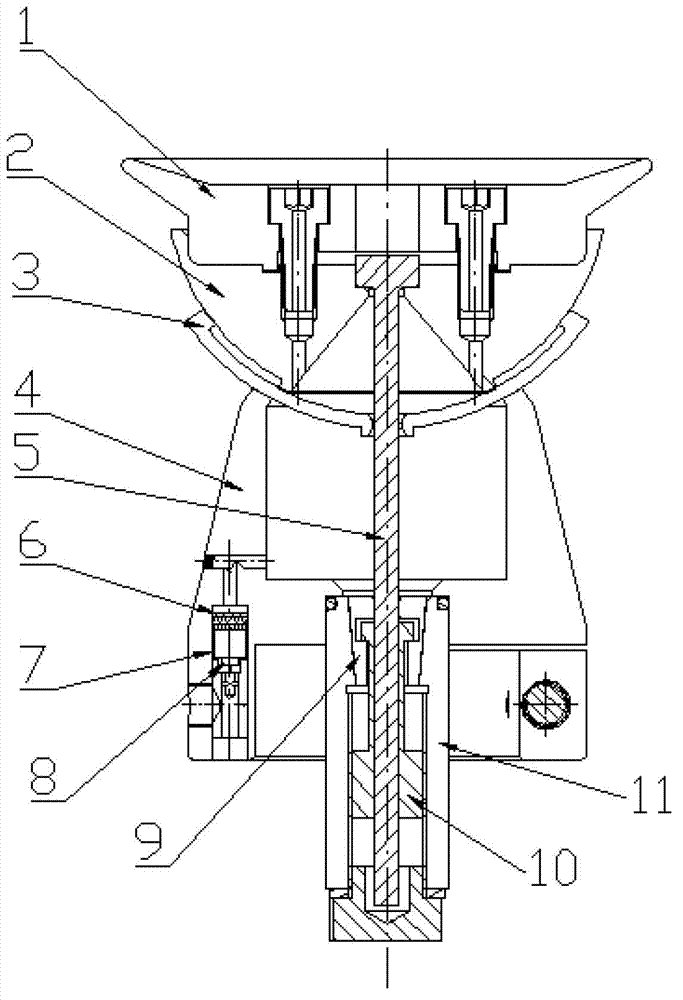

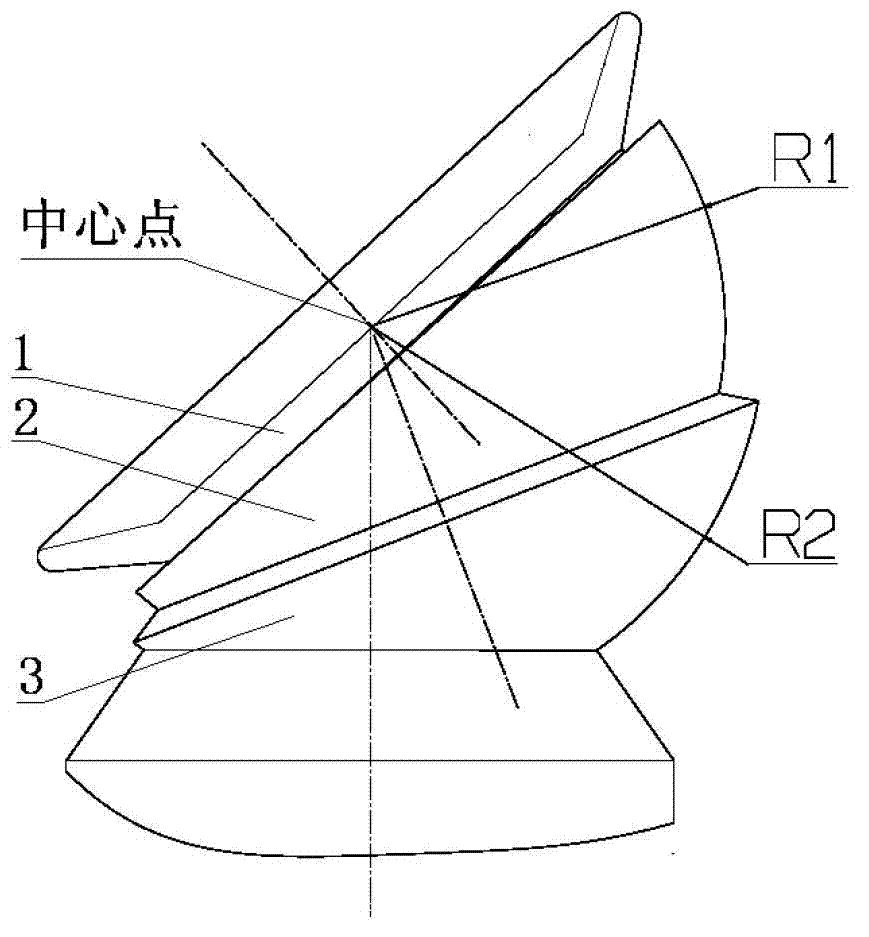

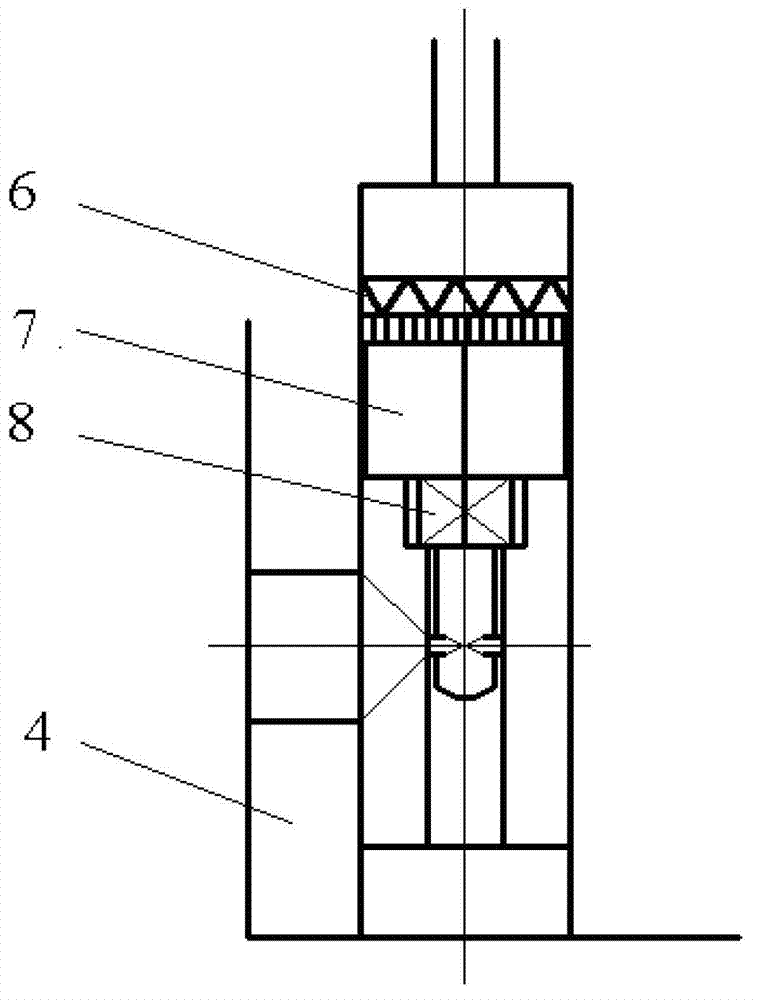

[0023] Universal vacuum suction cup with self-shutoff function is a device for adsorbing and fixing three-dimensional curved surface parts on flexible tooling; it consists of sealing lip suction cup 1, first layer of rotating ball bowl 2, second layer of rotating ball bowl 3, ball The bowl support 4, polyurethane elastic rubber (5), sealing sleeve 11, and the pinhole sliding block 7 and spring 8 installed on the ball bowl support are composed of;

[0024] The suction cup (1) of the sealing lip is made into a concave structure. The lip is made of polyurethane rubber inlaid on the steel core to ensure airtightness and durability during vacuum adsorption, and it is not easy to damage the workpiece. The steel core in the middle is made of There are vent holes and screw holes; the first layer of rotating bowl 2 is made of a concave and outer circle structure, the upper part is matched with the suction cup, and the two are connected as one by screws, and the outer surface is spherica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com