Automatic feed device for biscuit assembly packaging

An integrated packaging and automatic feeding technology, which is applied in the field of biscuit packaging, can solve the problems of low efficiency of biscuit packaging, achieve the effect of avoiding manual contact with biscuits, improving efficiency, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

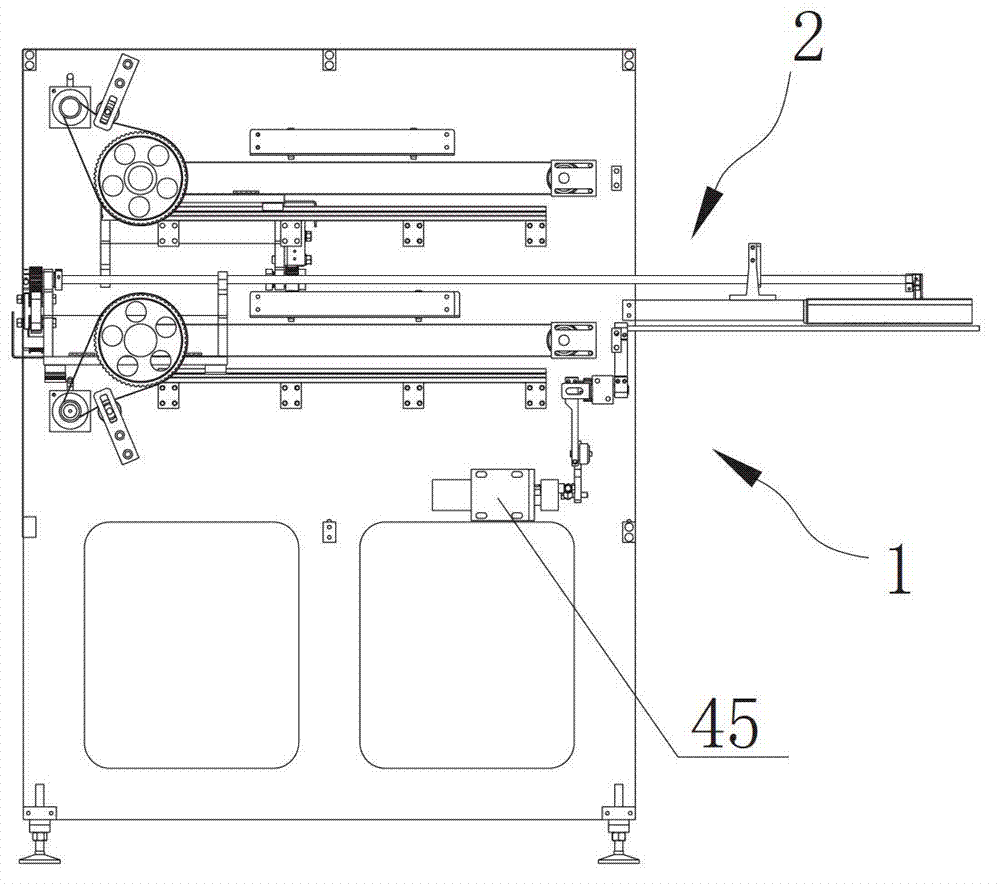

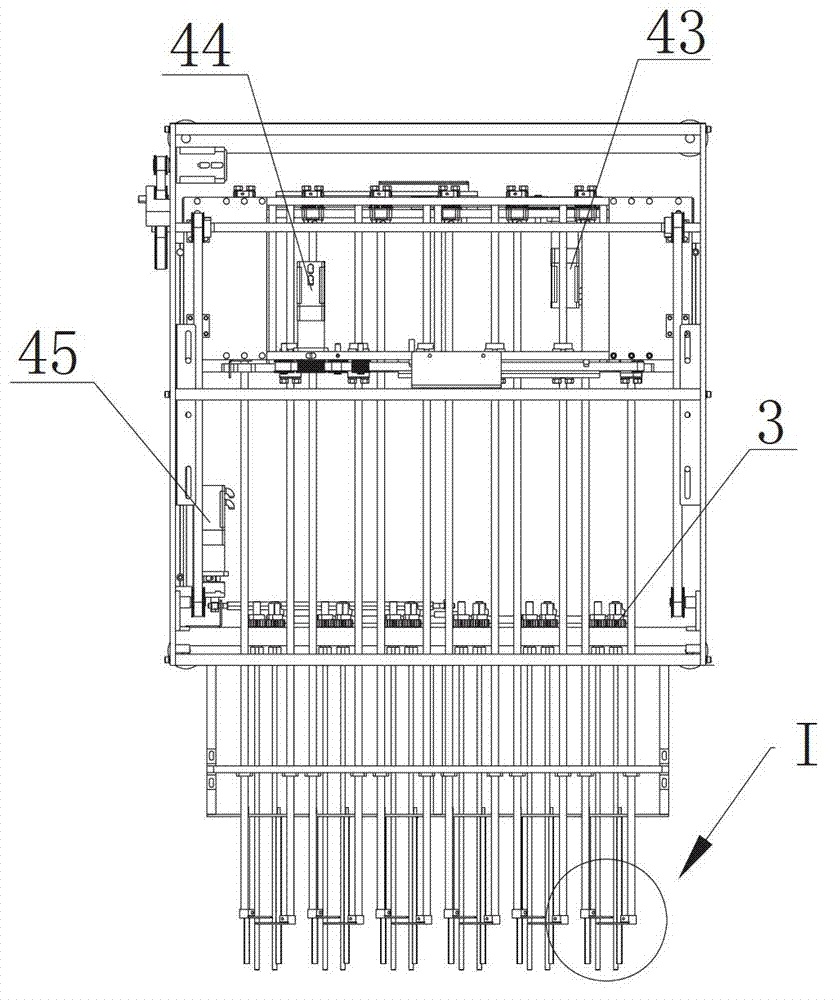

[0021] Such as figure 1 , figure 2 and image 3 As shown, the biscuit collective packaging automatic feeding device includes a supporting platform 1, a position-limiting and length-fixing mechanism 2 and a power mechanism. Among them, the supporting platform 1 needs to be located below the end of the biscuit production line during installation, and at the same time be located above the starting end of the packaging machine conveyor line, so that the biscuits produced by the biscuit production line can fall on the supporting platform 1 in time; The fixed-length mechanism 2 is set above the supporting platform 1, and is used to select a certain length of biscuits on the supporting platform 1. After selecting a suitable length (that is, a certain number of biscuits), these biscuits are removed from the supporting platform 1 It automatically falls into the feeding trough of the packaging machine conveyor line, and finally the packaging machine packs it into products. This cycle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com