Stern transom plate-free ship line and balanced rudder blade

A technology for balancing rudders and hulls, which is applied in rudder steering, ship parts, ship construction, etc. It can solve the problems of reduced rudder efficiency and increased gap scissors, and achieves improved rudder efficiency, improved maneuverability, and improved rudder efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the drawings and specific embodiments.

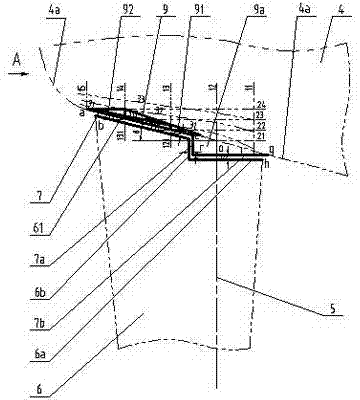

[0015] figure 1 It is a side view (direct section view) of the present invention, which shows the relative position of the rudder and the hull when the rudder is at a rudder angle of 0° when the partial straight section line is shown;

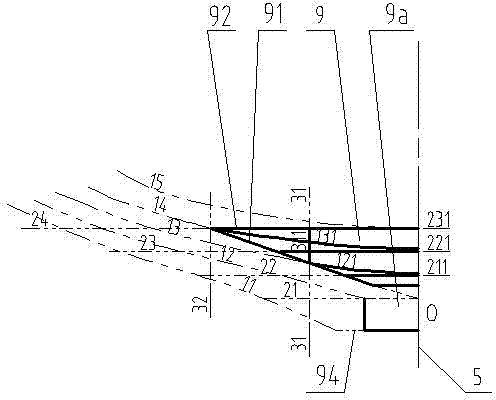

[0016] figure 2 It is the A-direction view (station view) of the present invention. Due to symmetry, only the port side part of the profile is shown;

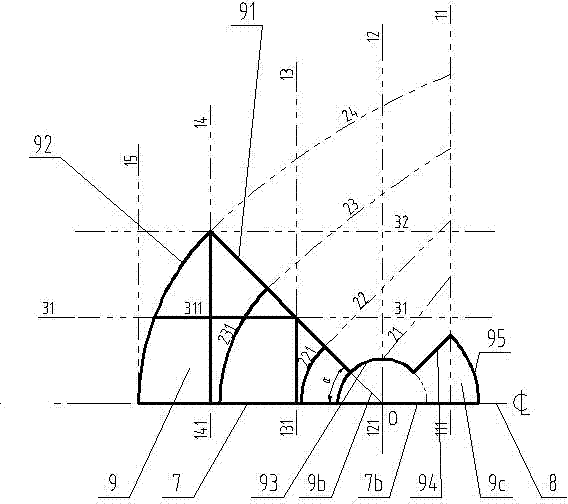

[0017] image 3 It is a B-direction view (a waterline surface view) of the present invention. Due to symmetry, only the port side part of the profile is shown.

[0018] Such as figure 1 , figure 2 , image 3 Shown:

[0019] The 0° straight section line of the hull is the straight section line of the hull passing through the centerline of the rudder stock;

[0020] Point o is the intersection of the rudder stock centerline 5 and the hull 0° straight section line 4a;

[0021] Point b i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com