Flap gate floating method

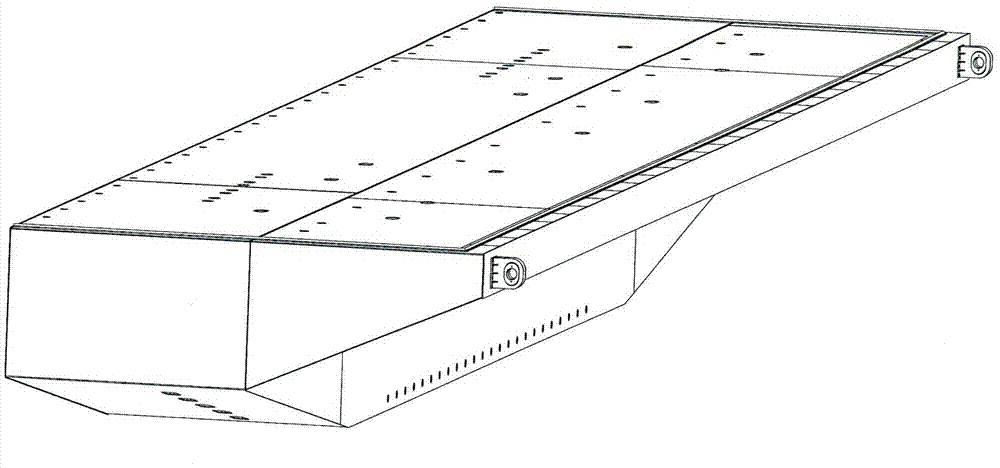

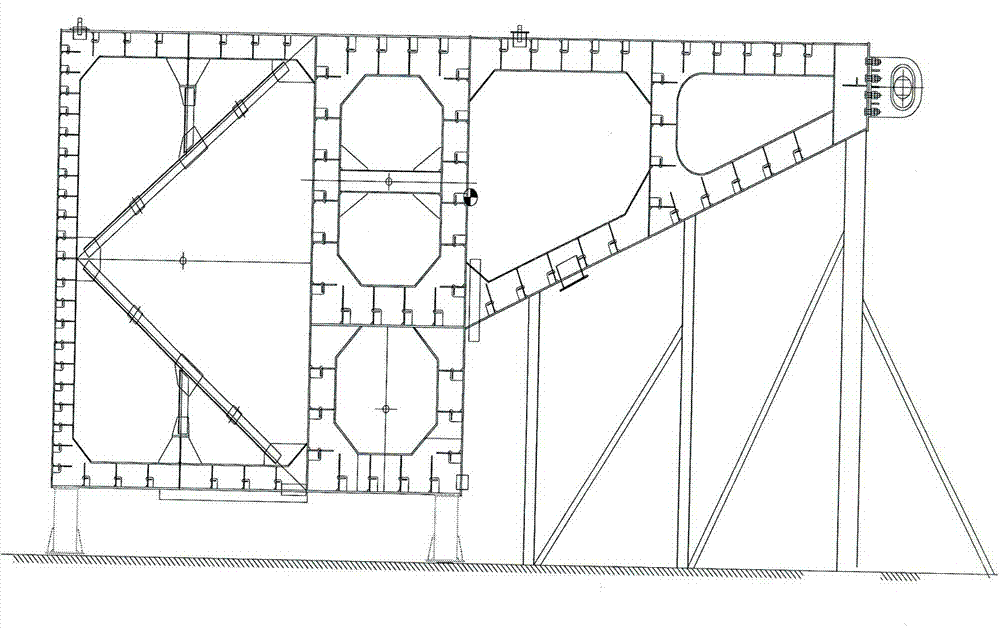

The technology of a horizontal and tilted dock door and dock door is applied in the directions of ship parts, ships, transportation and packaging, which can solve the problems of high risk, long construction period and large size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with specific embodiment the present invention is described in further detail:

[0019] 1. After the dock door is manufactured on the tire frame, put the relevant equipment prepared for the dock door towing in advance, design a set of busbars according to the dock door to be towed, use seawater to seal the bottom hole of the dock door, and Partially modify the upper plane of the dock door, and at the same time seal all the exhaust holes of the tidal chamber on the top of the dock door, install the quick joint of the air pipe on the blocking plate, so that the air enters the tidal chamber from the air pipe, and cover the upper surface of the fixed water tank with a flange Install two sets of air pipe quick joints on the top, so that the air enters the fixed water tank from the air pipes. After completion, connect the air pipes to the quick joints, and connect the other end to the air busbar to form a sealed structure, and make the cables and the ball ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com