Multi-purpose frame butt-welding die

A technology of butt welding and mold, applied in the field of multi-purpose machine base butt welding mold, can solve the problems of waste of manpower and material resources, long manufacturing cycle, inconsistent height and low size requirements of machine base corner plates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

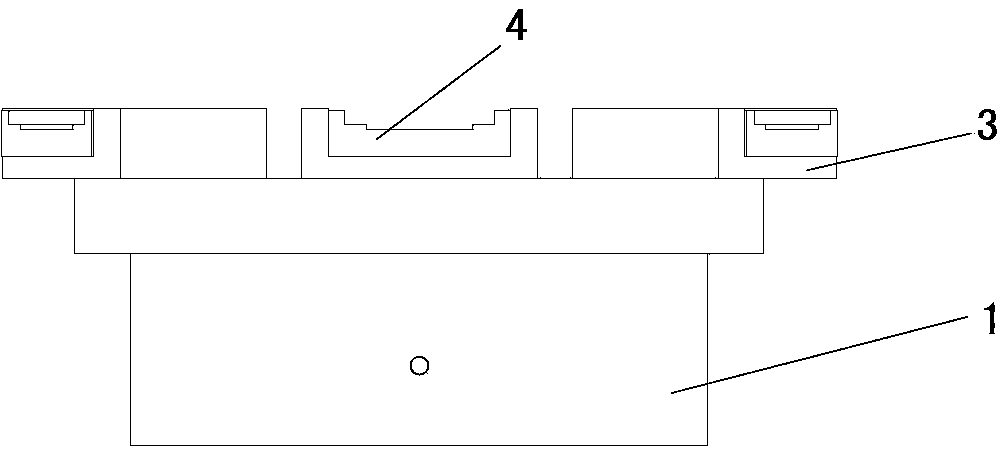

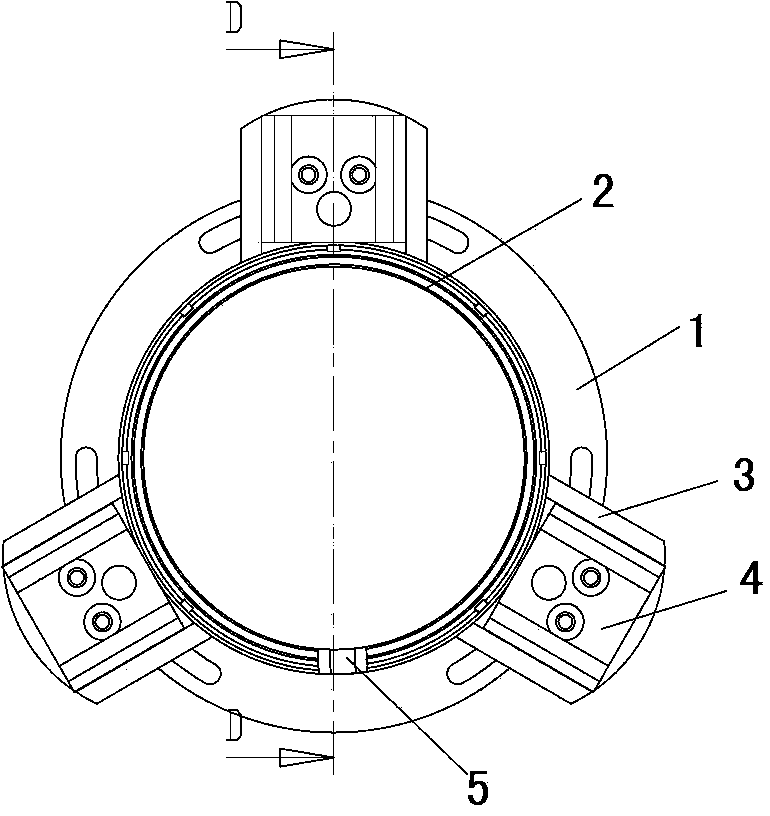

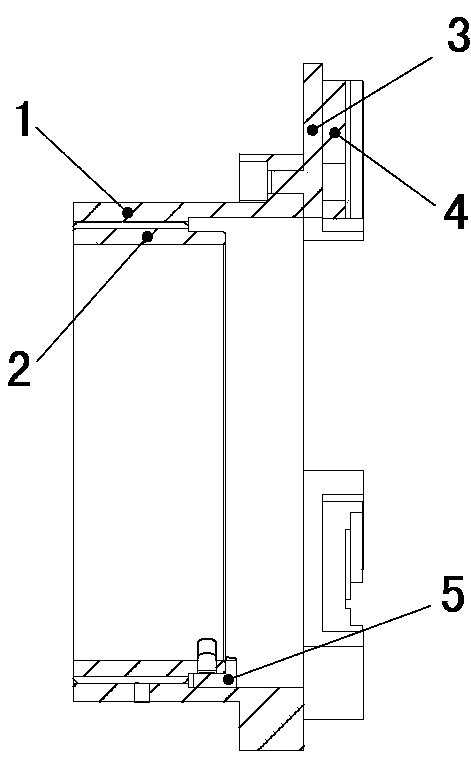

[0026] see figure 1 , with reference to figure 2 , image 3 , The multi-purpose butt welding mold of the machine base of the present invention includes an annular base body 1, a positioning plate 2, a sliding adjustment plate 3, a casing corner plate fixing block 4 and a casing positioning block 5.

[0027] Cooperate see Figure 4 , the upper end of the annular base 1 in the present invention is provided with a flanging, and three axially penetrating arc-shaped slots 11 are evenly spaced on the flanging.

[0028] Cooperate see Figure 5 , the positioning disc 2 in the present invention is arranged in the annular base body 1 and is threadedly connected with the annular base body and can move up and down, and a section of reduced-diameter section formed by reducing the outer diameter is arranged on the top of the positioning disc 2, and the reduced-diameter section There is a radially through slot 21 on the top, through which the housing positioning block 5 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com