Drum type electro-osmosis dehydrator for reducing power consumption by means of a narrow distance between a positive electrode and a negative electrode

A dehydrator and electro-osmosis technology, applied in the direction of dehydration/drying/concentrated sludge treatment, filtration separation, semi-permeable membrane separation, etc., can solve the problems of extending the distance between positive and negative electrodes, filter bag consumables, and hindering power supply, etc. To achieve the effect of narrowing the distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

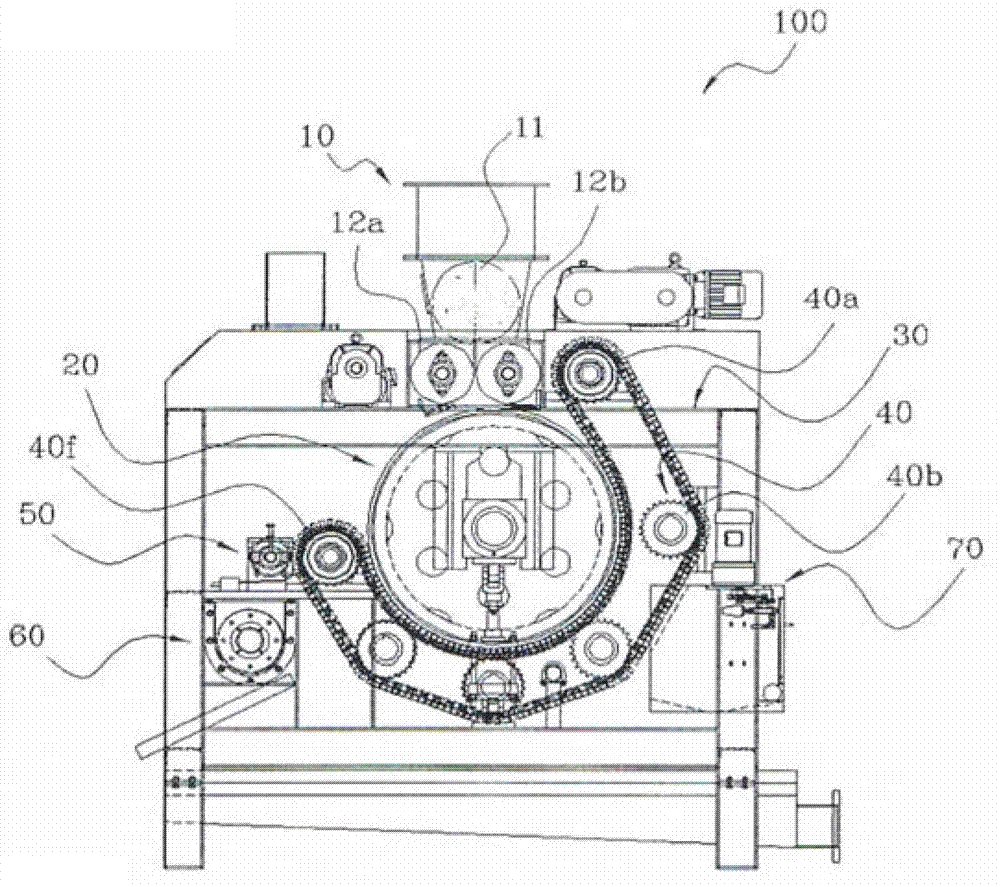

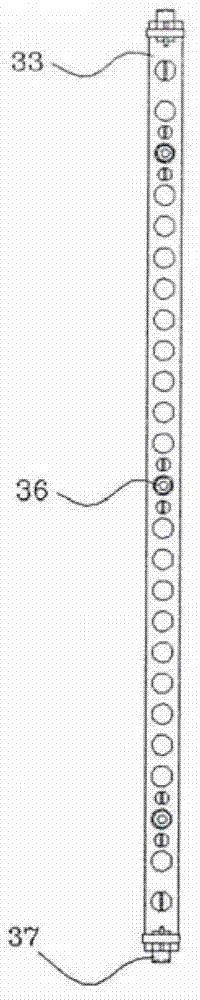

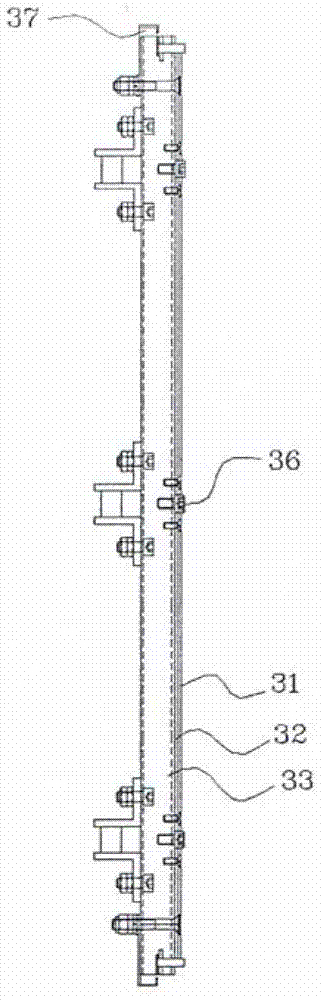

[0026] The drum-type electroosmotic dehydrator for saving electricity by reducing the distance between the positive electrode and the negative electrode will be described in detail below with reference to the accompanying drawings according to an embodiment of the present invention. figure 1 It is a front view of the electroosmotic dehydrator of the present invention. figure 2 It is the figure of the crawler belt of the electroosmosis dehydrator of the present invention, image 3 and Figure 4 It is the figure of the caterpillar part of the electroosmosis dehydrator of this invention.

[0027] refer to Figure 1 to Figure 4 , by reducing the distance between the positive and negative poles, the drum type electro-osmosis dehydrator (100) that realizes power saving includes a sludge supplier (10), a drum (20), a caterpillar (30), and an idler chain Wheels (Idle Sprocket; 40).

[0028] The sludge supplier (10) is located above the center of the electroosmotic dehydrator (100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com