Electrical equipment anti-misoperation method, device and system

A technology for electrical equipment and equipment operation, applied in the direction of circuit devices, electrical components, etc., can solve the problems of difficulty in writing anti-misoperation logic, difficulty in controlling accuracy, and low reliability, so as to achieve easy adjustment of rules, reduce difficulty, Effects that are not prone to errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The method for preventing misoperation of electrical equipment provided in this embodiment includes steps:

[0049] 11. Write equipment operation rule formulas that define the rules that need to be satisfied when performing each operation on each type of equipment.

[0050] According to the relevant operation management documents, equipment operating procedures, and on-site actual operation experience, the error prevention experts write the equipment operation rule formula. The equipment operation rule formula defines the rules that need to be satisfied during the closing and pulling operations of equipment such as knife switches, switches, and floor knives.

[0051] The composition and grammar of the equipment operation rule formula are:

[0052] The equipment operation rule formula is used to describe the operation rules of a certain type of equipment. The formula is divided into three parts: equipment type, operation type, and rule expression. This formula can be us...

Embodiment 2

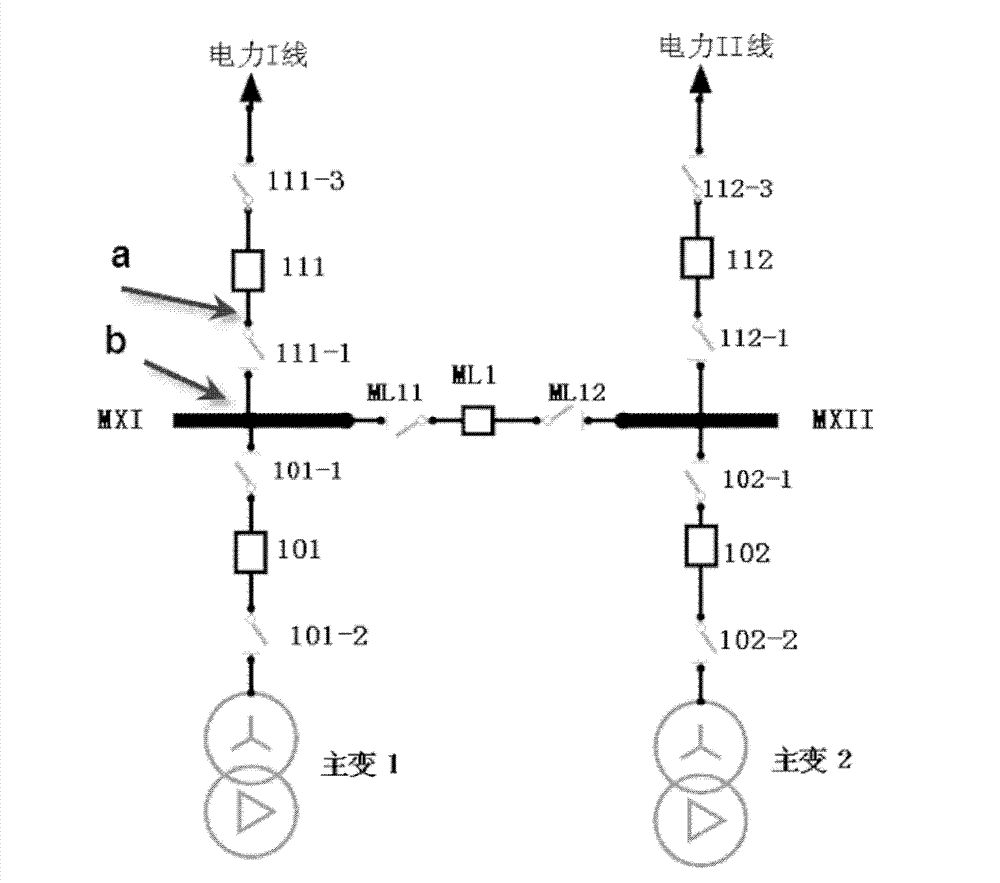

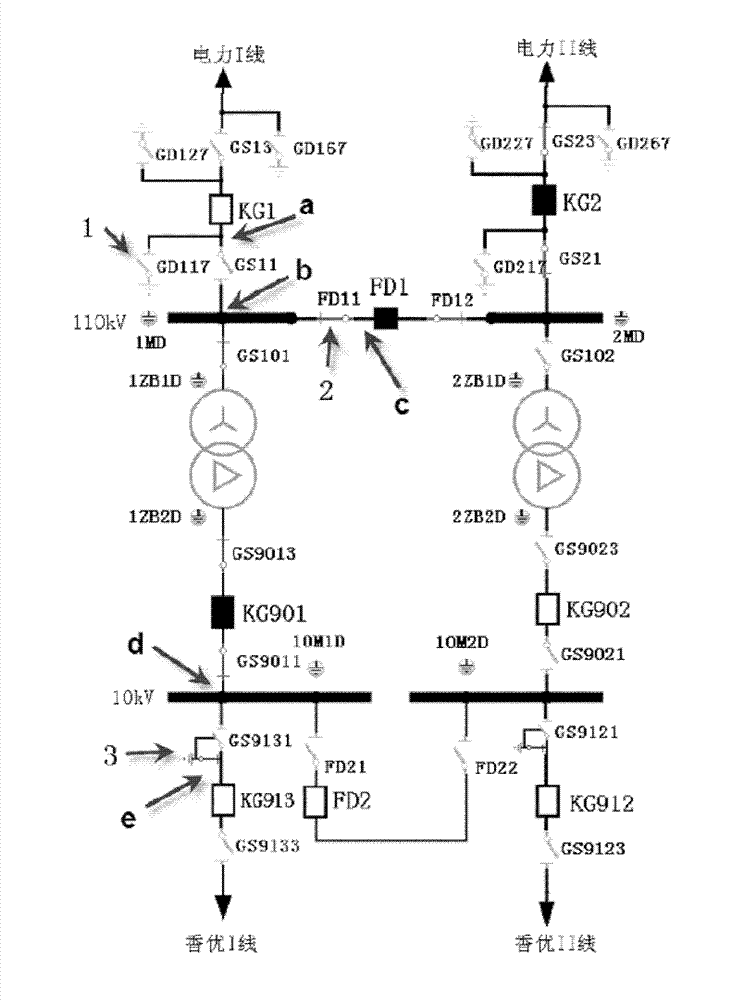

[0197] Such as image 3 As shown in the system wiring diagram, as a possible implementation mode, the anti-misoperation method provided by the present invention includes:

[0198] Step 21, write the equipment operation rule formula.

[0199] image 3 A variety of basic switch equipment and complex switch equipment are involved in the book. Taking -GD117 ground knife, -FD11 knife switch, and -GS9131 chain knife switch as examples, the method of writing the formula for the operation rules of the equipment is explained.

[0200] - The process of writing the formula for the operation rules of the GD117 ground knife is as follows:

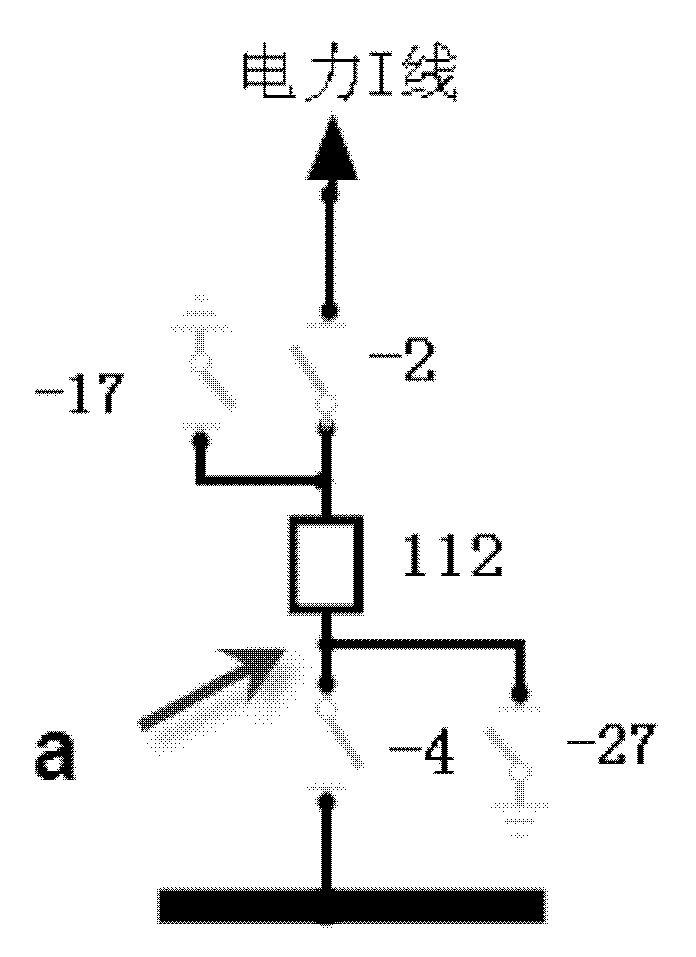

[0201] -GD117 ground knife is image 3 The equipment indicated by the middle arrow 1, the operating rules to be followed are essentially the same as figure 1 The -27 ground knife in the ground knife means that the relevant knife switches in all directions of the ground knife point are in the position, that is, when the ground knife is closed, the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com