Fixing device of optical fiber temperature sensor

A fiber optic temperature and fixing device technology, which is applied to thermometers, measuring devices, and parts of thermometers, etc., can solve problems such as fiber optic damage, inconvenient fiber optic temperature measurement, and transformers that cannot be protected by armor, and achieve the effect of preventing collision damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

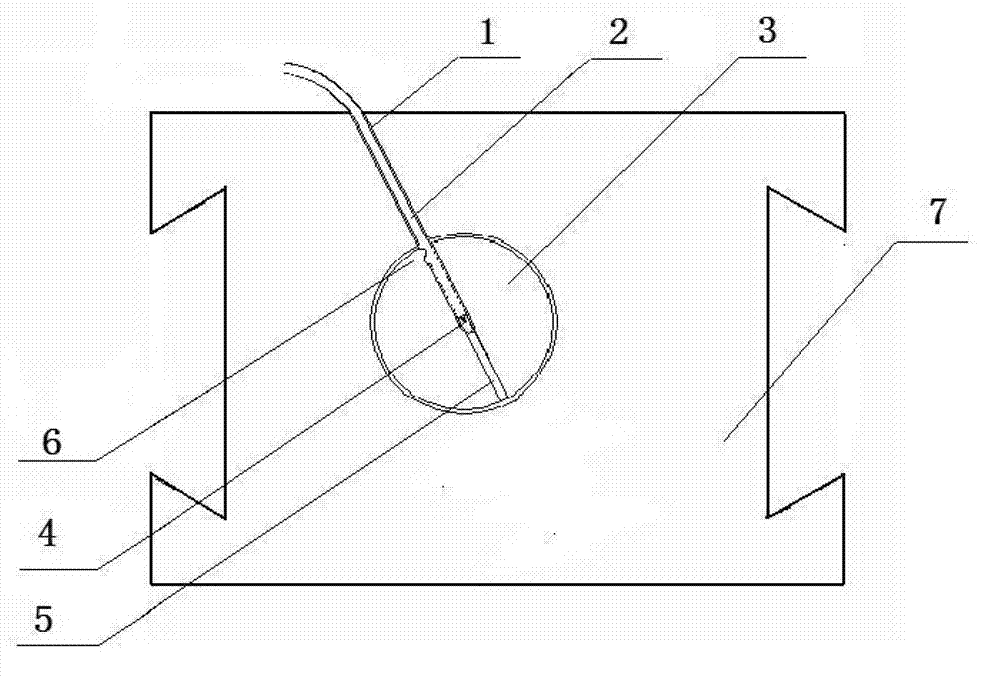

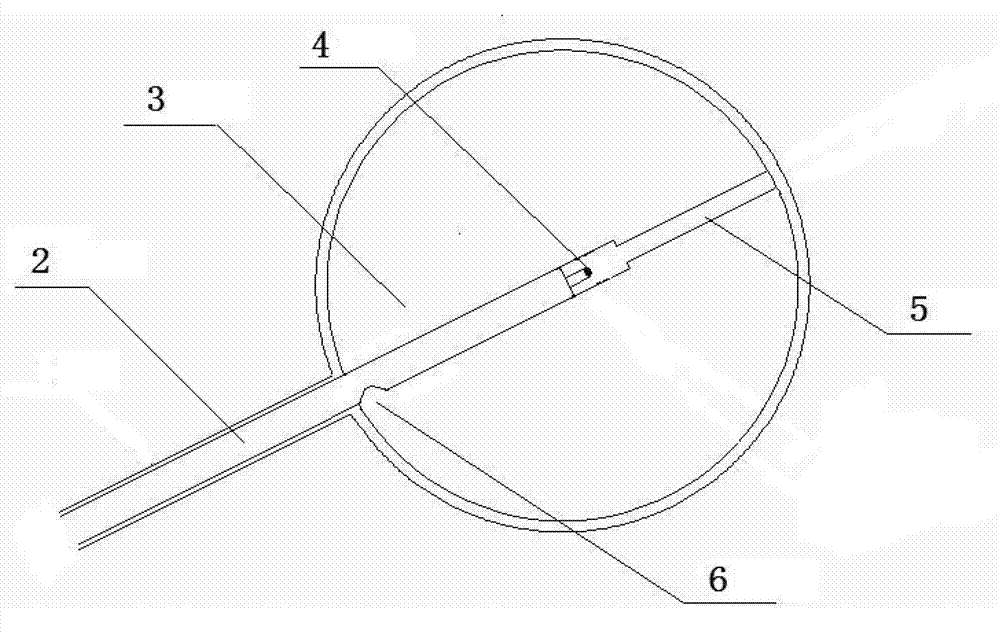

[0027] An optical fiber temperature sensor fixing device, comprising an insulating sheet 3, an optical fiber temperature sensor 4 and a pigtail 2, the insulating sheet 3 is provided with a groove 5, the optical fiber temperature sensor 4 is fixed inside the groove 5, and the The connector of the pigtail 2 is connected to the connector of the optical fiber temperature sensor 4 .

[0028] The surface of the pigtail 2 is coated with a package made of polytetrafluoroethylene.

[0029] The edge of the insulating sheet 3 is provided with a small protrusion, the pigtail 2 is fixed to the insulating sheet 3 provided with the small protrusion through a groove, and the surface of the package is provided with a groove matching the small protrusion. The insulating sheet 3 is circular. It also includes an insulating spacer 7, and a circular groove is arranged on the insulating spacer 7, and the insulating sheet 3 is fixed in the circular groove.

[0030] The insulating gasket 7 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com