Magnetic driving pump

A pump cover and pump shaft technology, applied in the field of magnetic drive pumps, can solve the problems of easy deformation, wear and tear, rupture and leakage of the isolation sleeve, and achieve the effect of superior hydraulic comprehensive performance and fresh and clean flow channels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

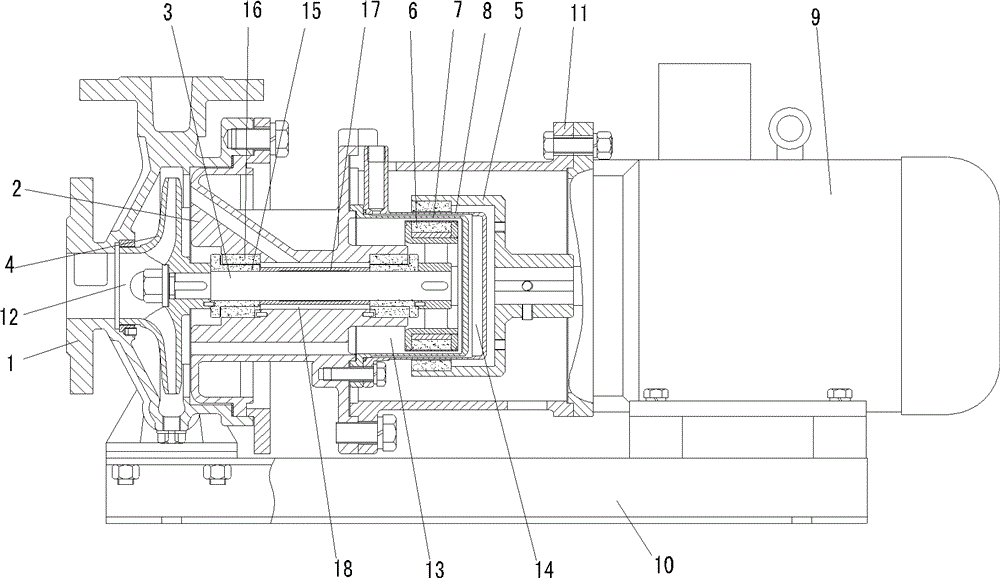

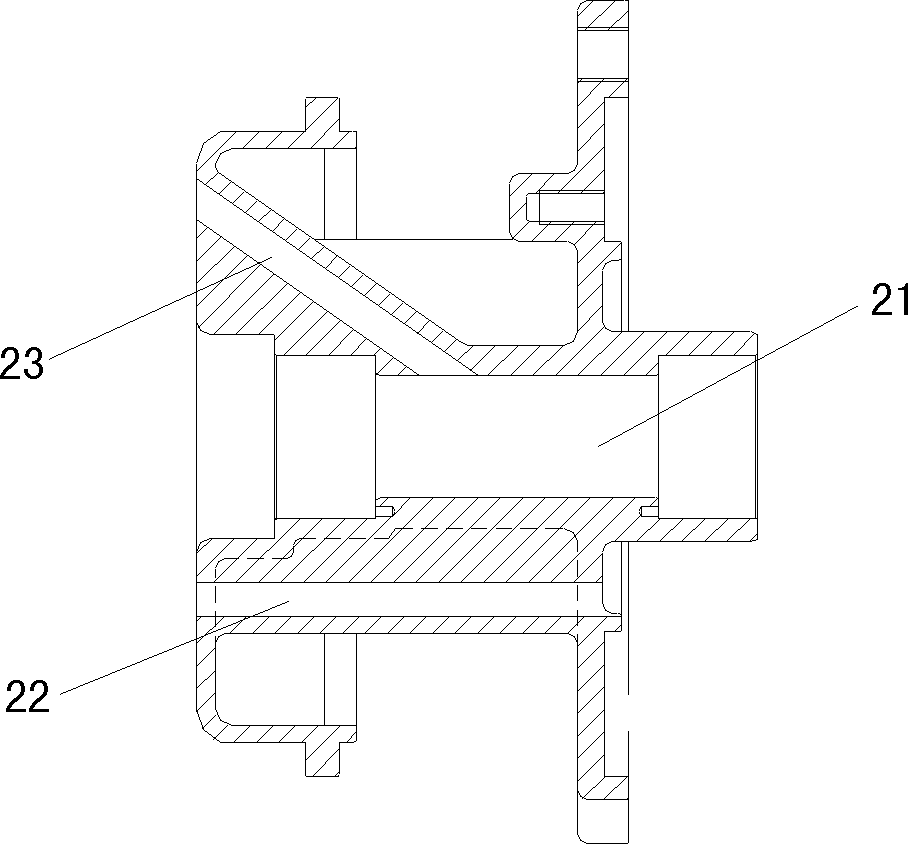

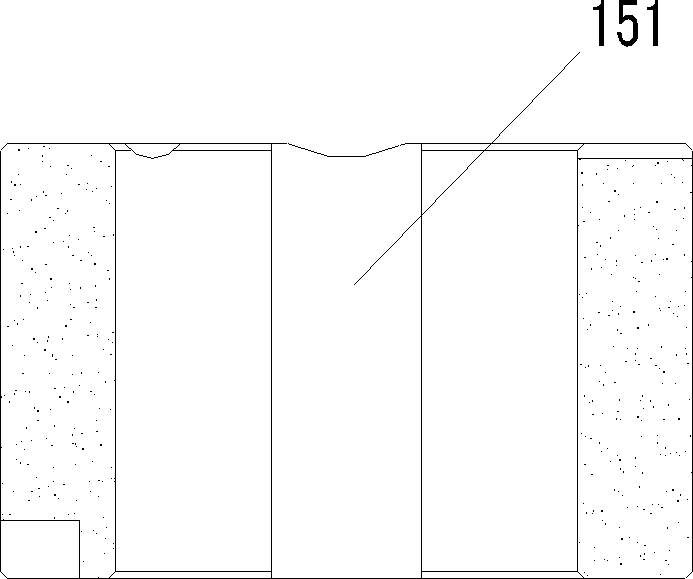

[0018] see figure 1 , with reference to Figure 2 to Figure 6 , the magnetic drive pump of the present invention comprises a pump body 1, a pump cover 2, a pump shaft 3, an impeller 4, an outer magnetic rotor 5, an inner magnetic rotor 6, a primary isolation sleeve 7, a secondary isolation sleeve 8 and a motor 9, the pump The body 1 and the motor 9 are installed on the base 10 . A connecting frame 11 is connected between the motor 9 and the pump cover 2 . A pump cavity 12 is formed between the pump cover 2 and the pump body 1, and an inner cavity 13 is formed between the pump cover 2, the inner magnetic rotor 6 and the primary isolation sleeve 7; the isolation sleeve is arranged between the outer magnetic rotor 5 and the inner magnetic rotor 6 , wherein the first-stage isolation sleeve 7 is arranged on the side close to the inner magnetic rotor 6, the second-level isolation sleeve 8 is arranged on the side close to the outer magnetic rotor 5, and an interval is provided betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com