Bin level measuring device

A technology of material level measurement and material distribution device, which is applied in packaging, loading/unloading, transportation and packaging, etc. It can solve the problems of high labor intensity, high risk, and easy misoperation, so as to reduce labor quota and improve working environment , good loading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

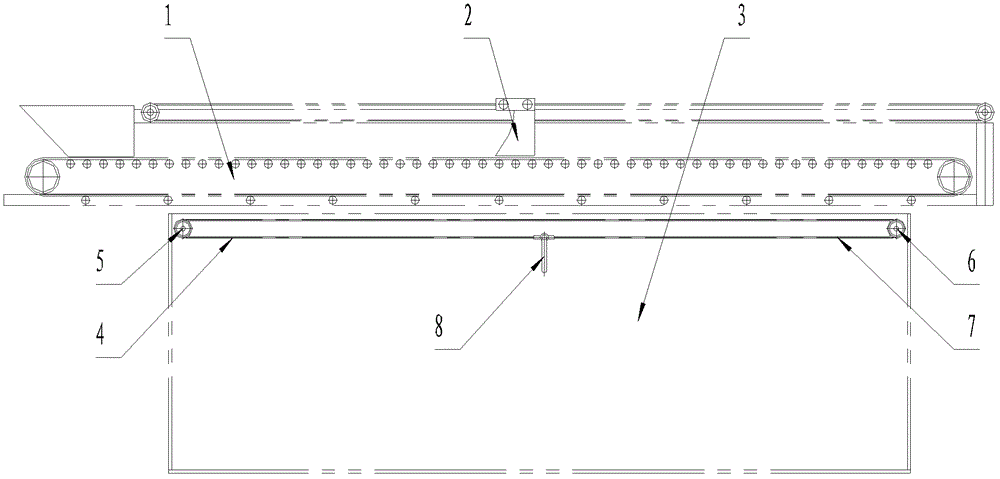

[0022] Figure 1 to Figure 4 It is the bin material level measuring device described in Example 1. The device includes a sensing mechanism 8 and a traction mechanism 4. The sensing mechanism 8 includes a rocking bar 9, a sensor 12 and a fixed seat 11. The rocking bar 9 is hinged with the fixed seat 11 through a shaft 10, and the rocking bar 9 can swing around the fixed seat 11. The sensor 12 is arranged on the fixed seat 11 , and the sensor 12 can be triggered by the swing of the rocker 9 . Traction mechanism 4 comprises driving wheel 5, reversing wheel 6 and rope 7, and driving wheel 5, reversing wheel 6 are respectively arranged on the inner wall of case storehouse 3 two ends, and rope 7 is wound on driving wheel 5 and reversing wheel 6, transmits The fixed base 11 of the sensing mechanism 8 is installed on the rope 7, and the rope 7 drives the sensing mechanism 8 to move in the length direction of the case storehouse 3 under the driving of the driving wheel 5.

[0023] Th...

Embodiment 2

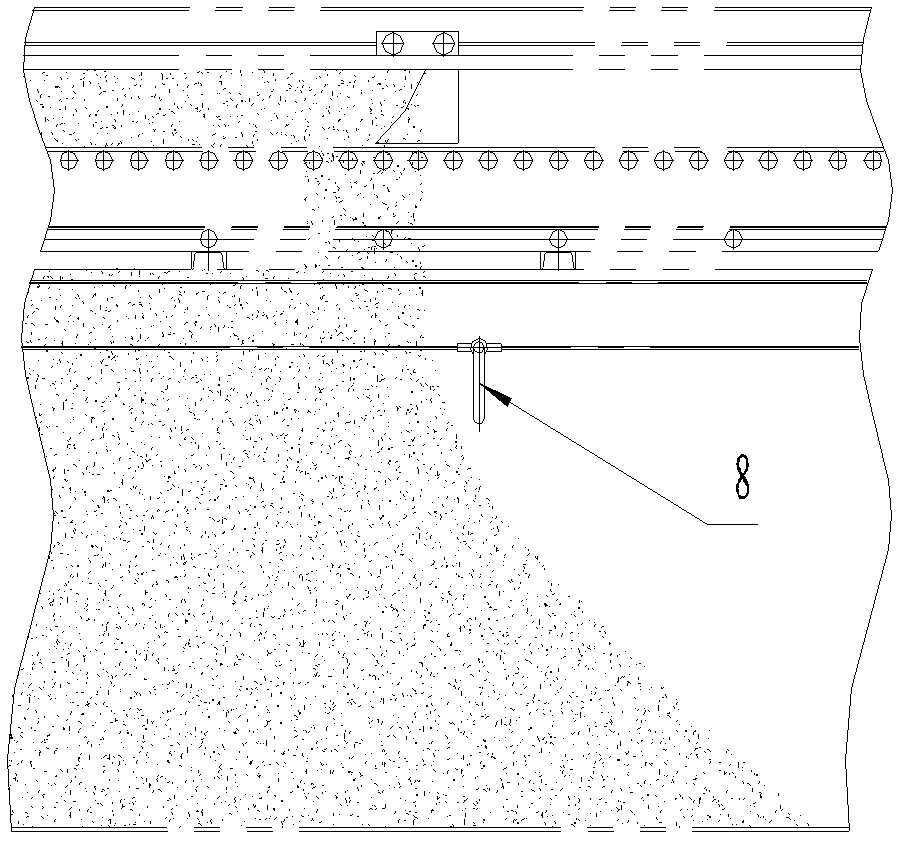

[0027] Figure 5 It is the bin material level measuring device described in embodiment 2. The difference from Embodiment 1 is that the traction mechanism 4 of the bin material level measuring device and the traction mechanism of the material distribution device 1 are a set of mechanisms, the sensing mechanism 8 is installed on the rope 7, and the rope 7 is redirected by the reversing wheel 6 Make the unloader 2 and the sensing mechanism 8 move synchronously.

[0028] Others are with embodiment 1.

Embodiment 3

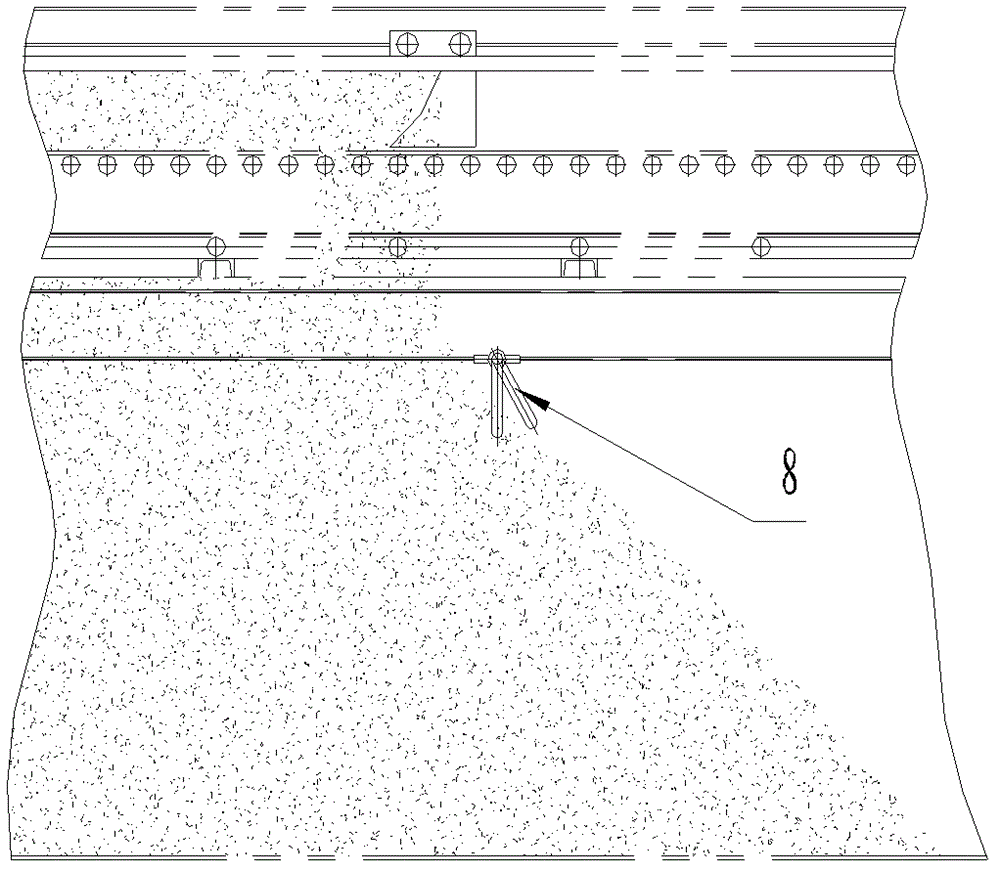

[0030] Figure 6 and Figure 7 It is the bin material level measuring device described in embodiment 3. The difference from Embodiment 1 is that both the bin material level measuring device and the distributing device 1 are installed on the top of the bin bin 3, and in the bin bin material level measuring device, one end of the fixing seat 11 of the sensing mechanism 8 is installed on the unloader 2, the other end of the fixed seat 11 and the rocking bar 9 are hinged by a shaft 10, and one end of the shaft 10 is connected to the sensor 12, so the unloader 2 can drive the sensing mechanism 8 to move synchronously.

[0031] When the material in the bin 3 is close to the top, the material slides or rolls down along the accumulation surface, pushes the rocker 9, makes the rocker 9 swing at a certain angle, triggers the sensor 12, and the sensor 12 sends out a signal to make the material distribution device 1 unload The device 2 moves toward the empty bin of the bin 3, and at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com