Mobile rail transit locomotive vehicle bogie frame maintenance platform

A rail transit and maintenance platform technology, applied in the direction of conveyors, conveyor objects, mechanical conveyors, etc., can solve problems such as system blockage, and achieve the effect of high load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

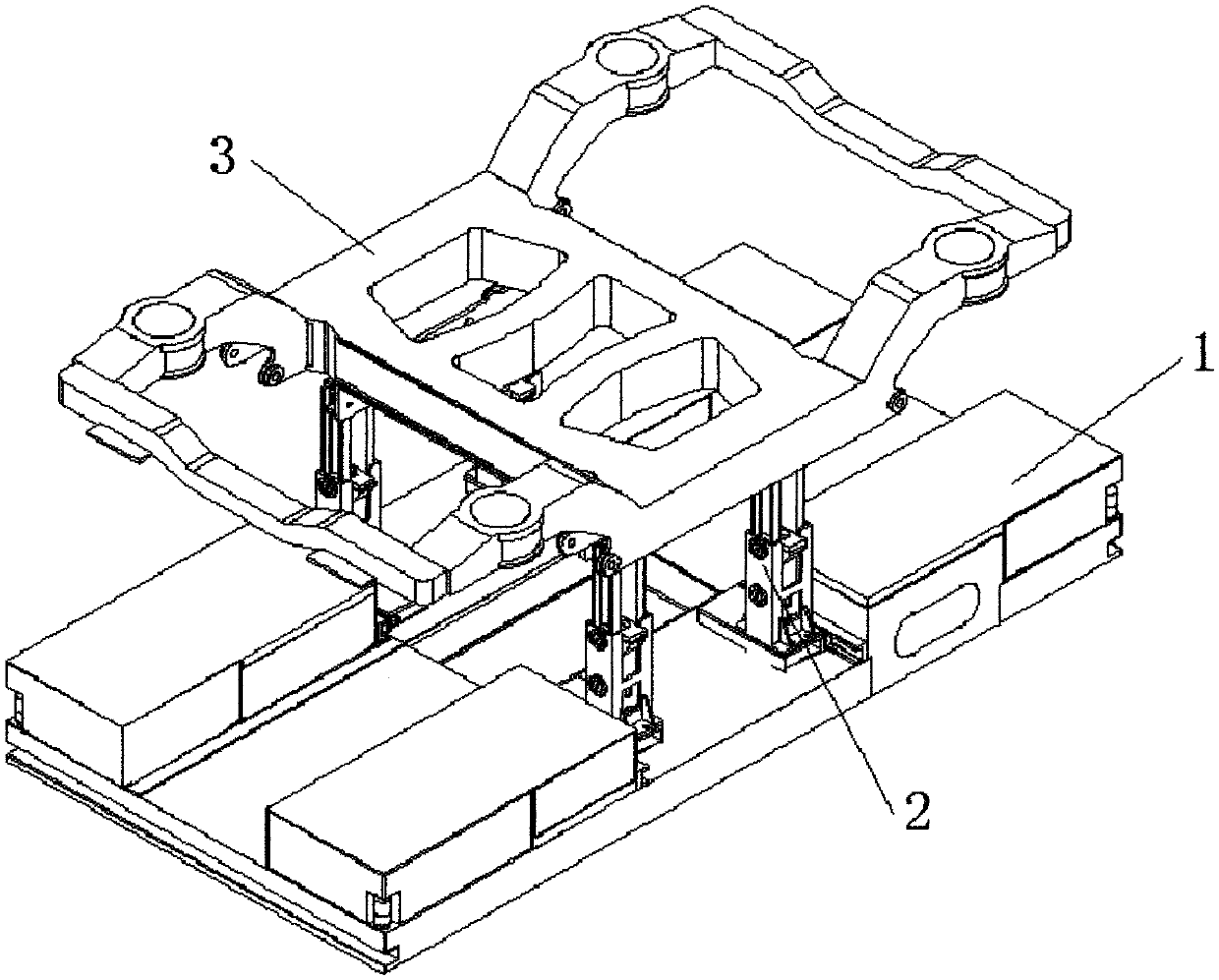

[0017] like figure 1 As shown, the mobile rail transit locomotive vehicle bogie frame maintenance platform of the present invention includes a frame AGV car 1 and a liftable support device 2 installed on the frame AGV car 1 for supporting the frame 3 .

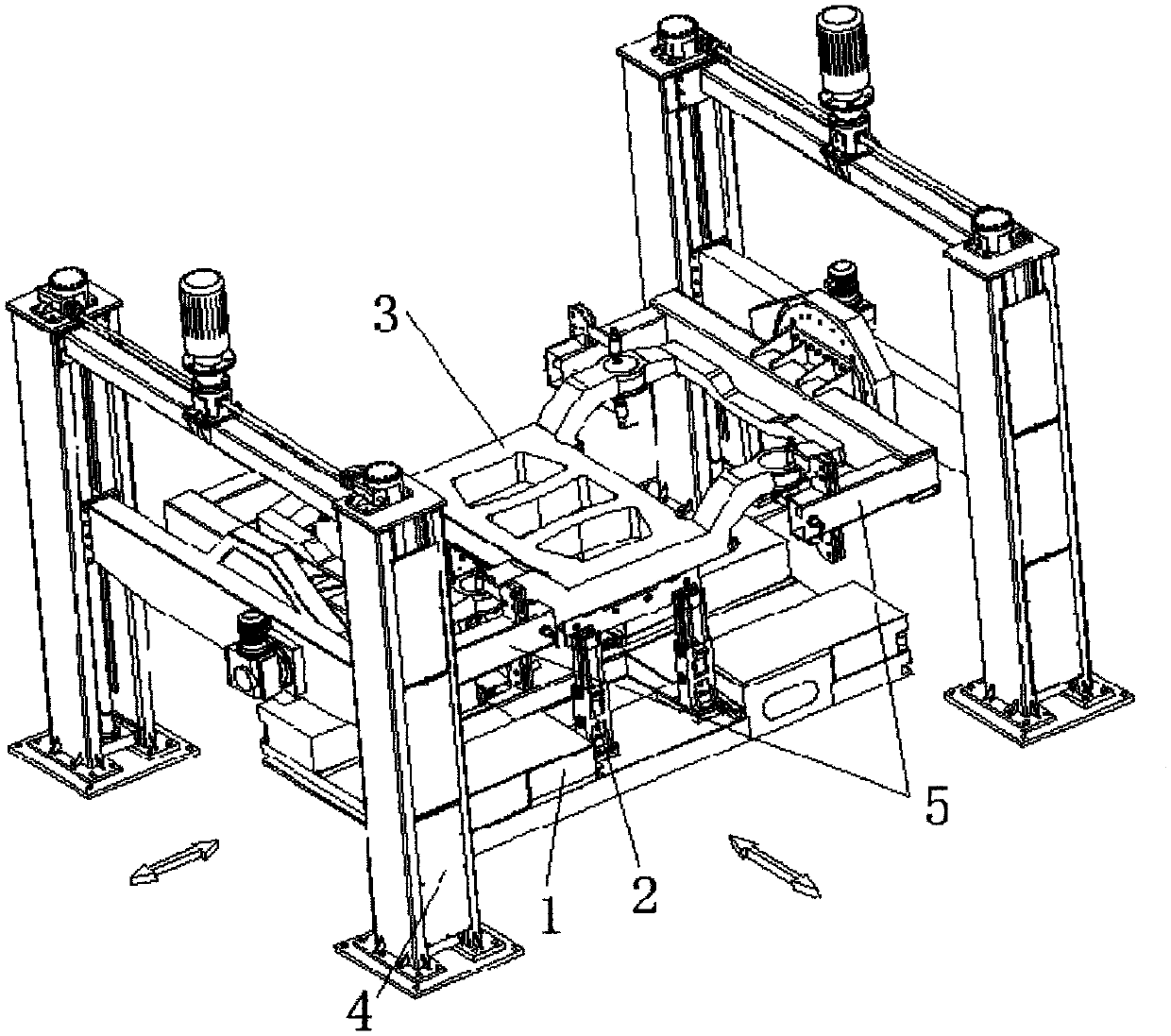

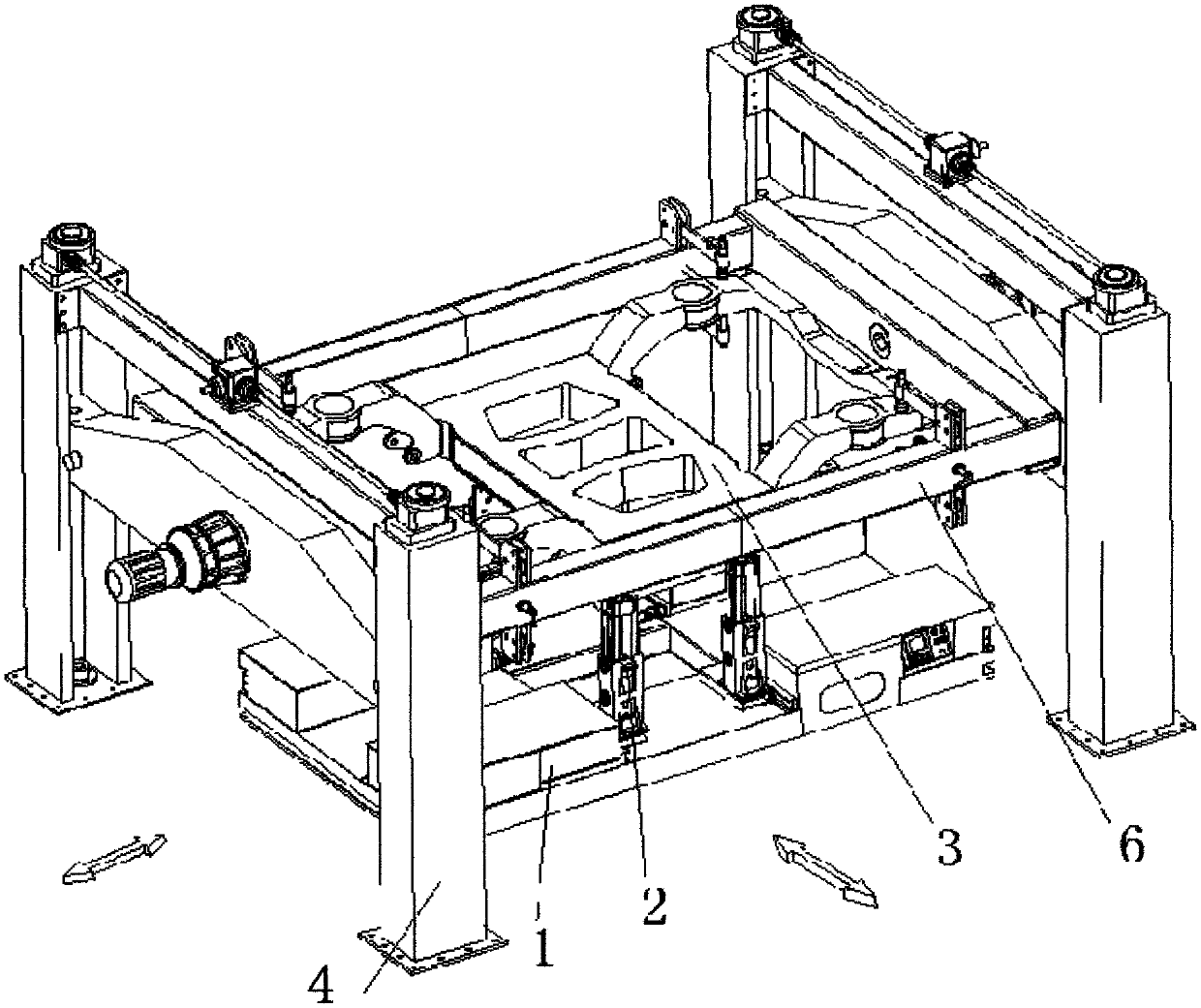

[0018] like figure 2 , 3 , 4, 5, 6, and 7, the mobile rail transit locomotive vehicle bogie frame maintenance platform of the present invention also includes a gantry integral overturning device and a gantry split overturning device that are matched with the frame AGV car 1 1. A suspension conveying device 7 for frame paint drying operations, a frame lifting device 8, a frame horizontal turning device 9 and a column type vertical turning device 10. The gantry integral overturning device includes an overturning machine 4 and an integral overturning frame 6 . The gantry split turning device includes a turning machine 4 and a split turning frame 5 .

[0019] The framework AGV vehicle can seamlessly connect with several maint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com