Upper cutter shaft regulation device of amorphous strip precision shearing machine

A technology of amorphous strips and adjustment devices, which is applied in the direction of shearing devices, feeding devices, automatic control devices, etc., can solve the problem of inability to quickly and accurately adjust the gap between the upper and lower cutter heads synchronously, affect the shearing efficiency and cutting quality, and cannot Quickly and accurately adjust side clearance and other issues to achieve the effect of ensuring cutting accuracy and cutting quality, improving precision and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

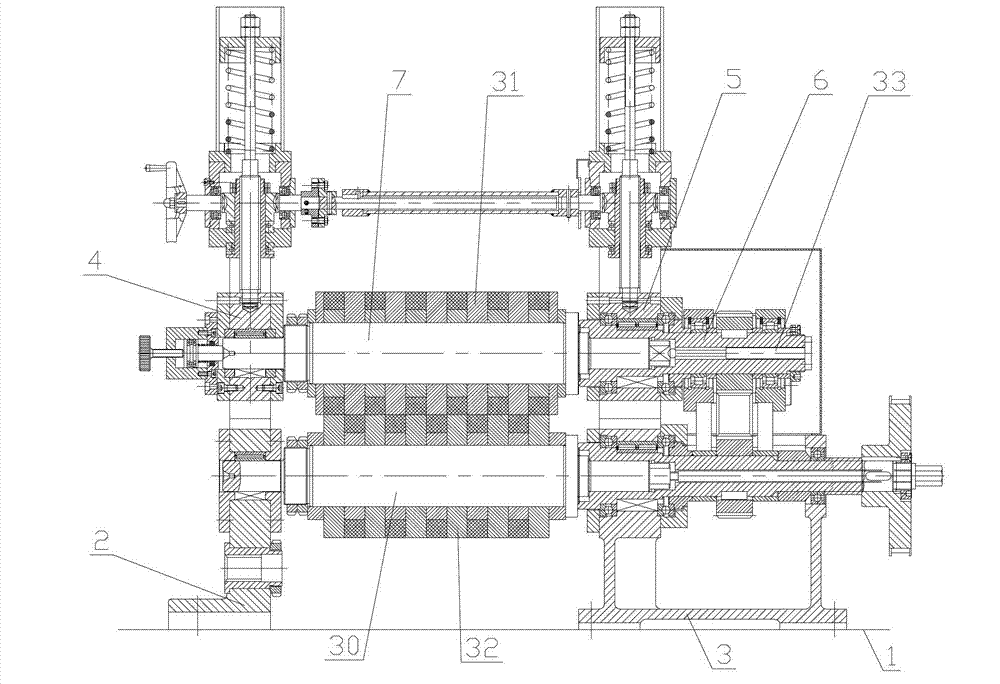

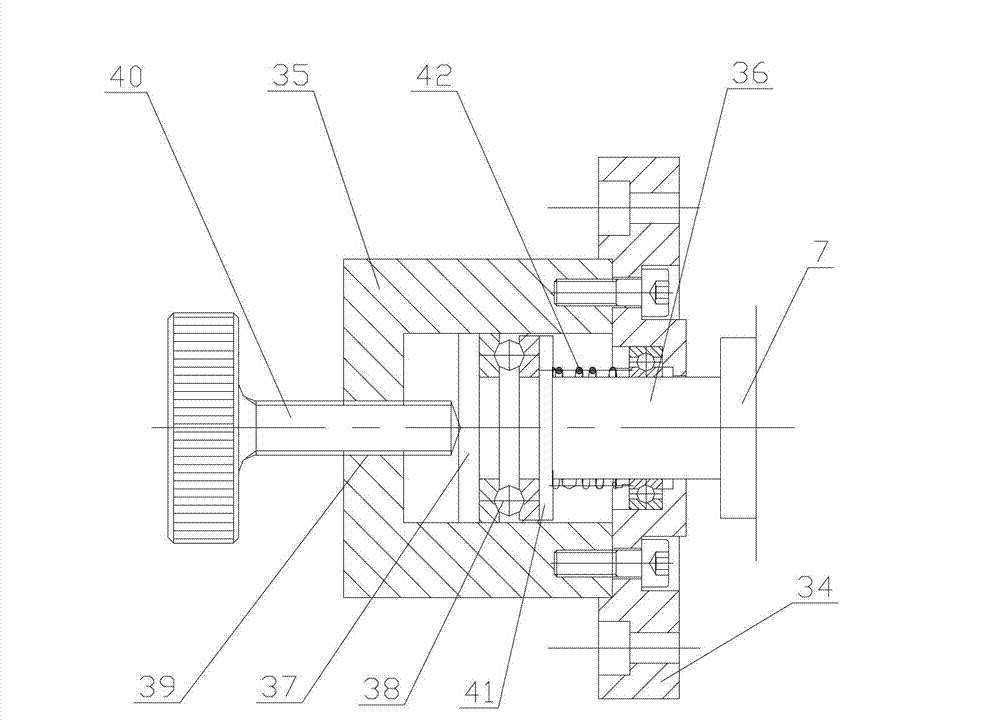

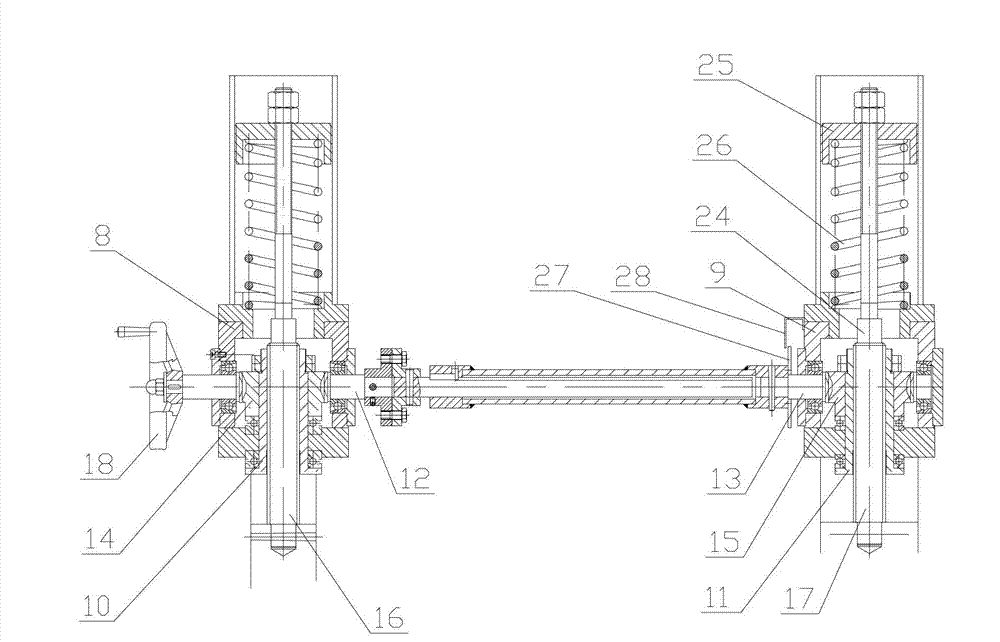

[0024] Attached below figure 1 -7 describes an embodiment of the present invention.

[0025] A synchronous lifting adjustment device for the upper cutter shaft of an amorphous strip precision shearing machine, including a base 1, a movable left wall panel 2 and a fixed right wall panel 3 are arranged on the table of the base 1, and the left wall panel 2 and the right wallboard 3 are symmetrically equipped with a left slider 4 and a right slider 5, the right slider 5 is equipped with a transmission shaft 6 through a bearing, and the right end of the upper cutter shaft 7 is inserted into the inner cavity of the transmission shaft 6 The left half is key-coupled with the transmission shaft 6, the left end of the upper cutter shaft 7 is installed on the left slider 4 through a bearing, and the upper ends of the left wallboard 2 and the right wallboard 3 are symmetrically fixed with a left adjustment support 8 and a right Adjusting support 9, the inner cavity of left adjusting supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com