A kind of acidic silicon-aluminum catalytic material

A catalytic material, acid silicon technology, applied in catalytic cracking, physical/chemical process catalyst, cracking and other directions, can solve the problems of high price and stability of organic silicon, uneven distribution of silicon and aluminum, low impurity content, etc. The effect of oil micro-reactivity, obvious pore characteristics, and concentrated pore distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] This example illustrates the preparation of the acidic silicon-aluminum catalytic material provided by the present invention.

[0020] The preparation process of this embodiment is the same as that described in CN1565733A. Set the concentration to 90gAl 2 O 3 / L of Al 2 (SO 4 ) 3 Solution and concentration is 102gAl 2 O 3 / L, NaAlO with a caustic ratio of 2.5 2 The solution is co-flowed into the continuous gel-forming kettle, keeping the gel-forming pH=10, collecting quantitative gel-forming slurry, and adding 60g SiO under stirring conditions 2 / L water glass, warm to 80℃ for 2 hours; use NH 4 Cl solution according to sediment (dry basis): ammonium salt: H 2 The weight ratio of O=1:0.8:15, the silicon-aluminum precipitate was ion-exchanged at 60°C to remove sodium ions. The exchange was repeated twice for 0.5 hours each time, and then the resulting filter cake was re-pulped and pressed according to fluorosilicone. Acid: Material dry basis: H 2 The weight ratio of O=0.04:1:...

Embodiment 2

[0026] This example illustrates the preparation of the acidic silicon-aluminum catalytic material provided by the present invention.

[0027] The preparation process is the same as in Example 1, wherein the adding ratio of fluorosilicic acid is fluorosilicic acid: dry basis of material: H 2 O=0.08:1:8, the acidic silicon-aluminum catalytic material is obtained after washing and drying. Denoted as BSA-2.

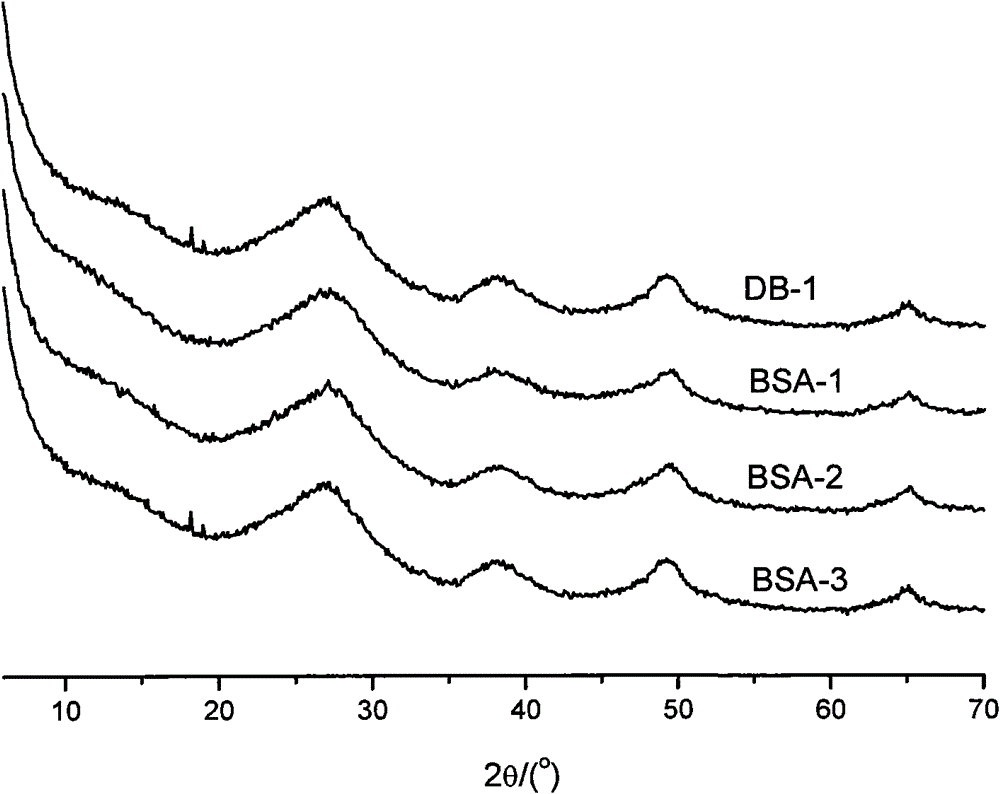

[0028] The X-ray diffraction spectrum of BSA-2 is shown in figure 1 Medium; Crystallinity and elemental analysis chemical composition are listed in Table 1; Pore parameters such as specific surface area and infrared acidity data are listed in Table 2.

Embodiment 3

[0030] This example illustrates the preparation of the acidic silicon-aluminum catalytic material provided by the present invention.

[0031] The preparation process is the same as in Example 1, wherein the adding ratio of fluorosilicic acid is fluorosilicic acid: dry basis of material: H 2 O=0.12:1:8, after washing and drying, the acidic silicon-aluminum catalyst material is obtained. Denoted as BSA-3.

[0032] The X-ray diffraction spectrum of BSA-3 is shown in figure 1 Medium; Crystallinity and elemental analysis chemical composition are listed in Table 1; Pore parameters such as specific surface area and infrared acidity data are listed in Table 2.

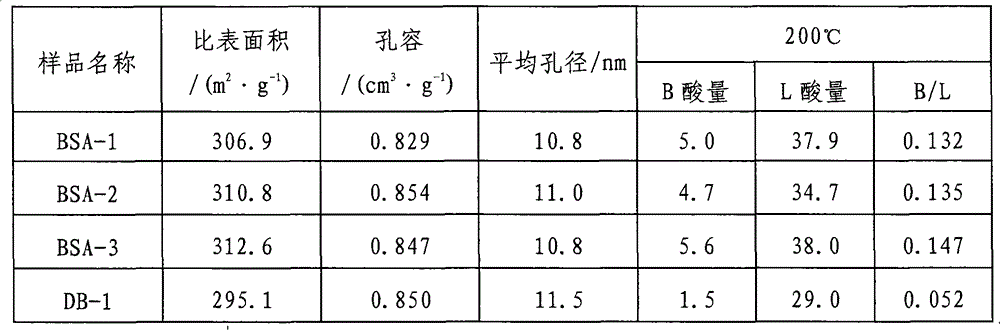

[0033] It can be seen from the table that the acidic silicon-aluminum catalytic material provided by the present invention has significantly improved crystallinity compared with the comparative material DB-1, and the ratio of B acid to L acid is more than doubled.

[0034] Table 1

[0035] sample name

Crystallinity / %

Na 2 O / %

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com