Electric heating glass kettle and assembling method thereof

A technology of electric heating glass and assembly method, which is applied in the direction of heating devices, water boiling utensils, and special materials for cooking utensils, etc., which can solve the problems of high cost and unsightly appearance, and achieve high production efficiency, extended service life, beautiful and elegant appearance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

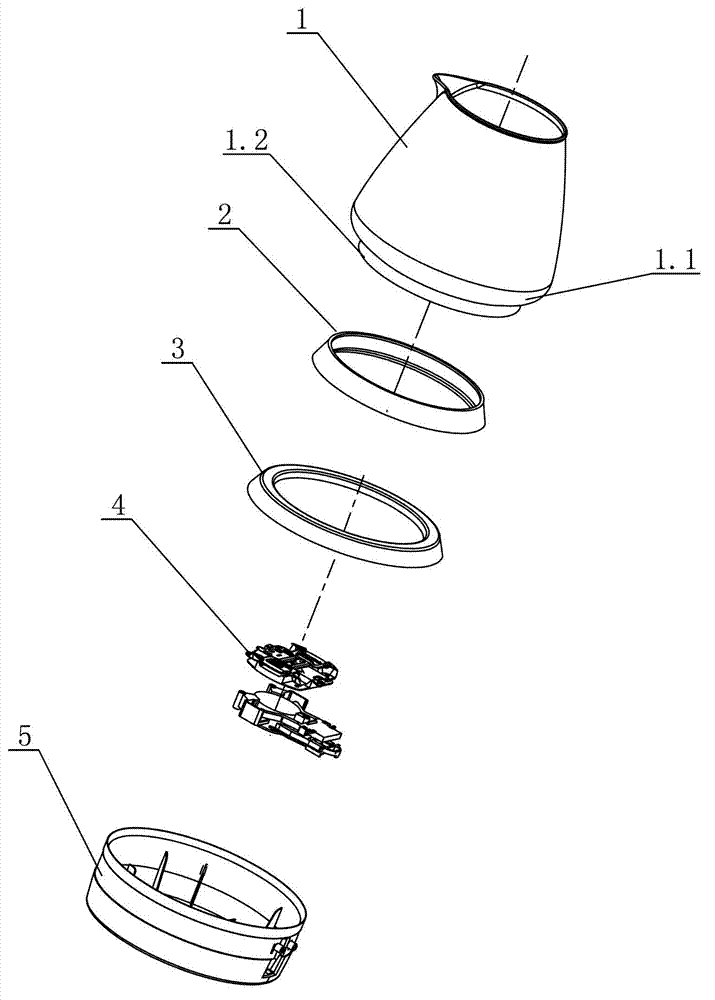

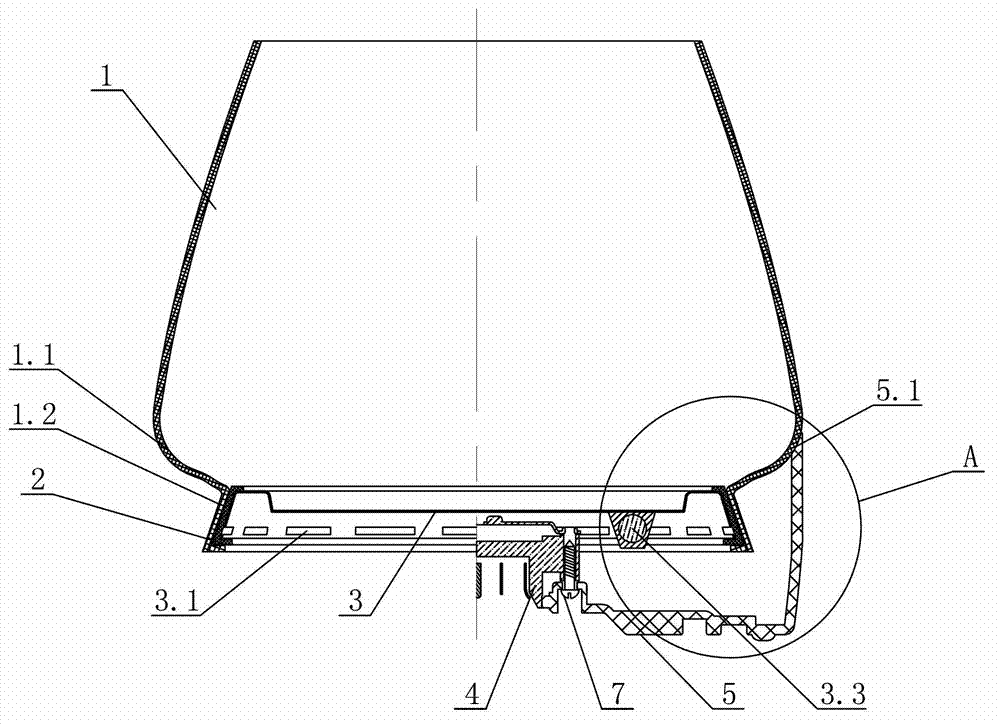

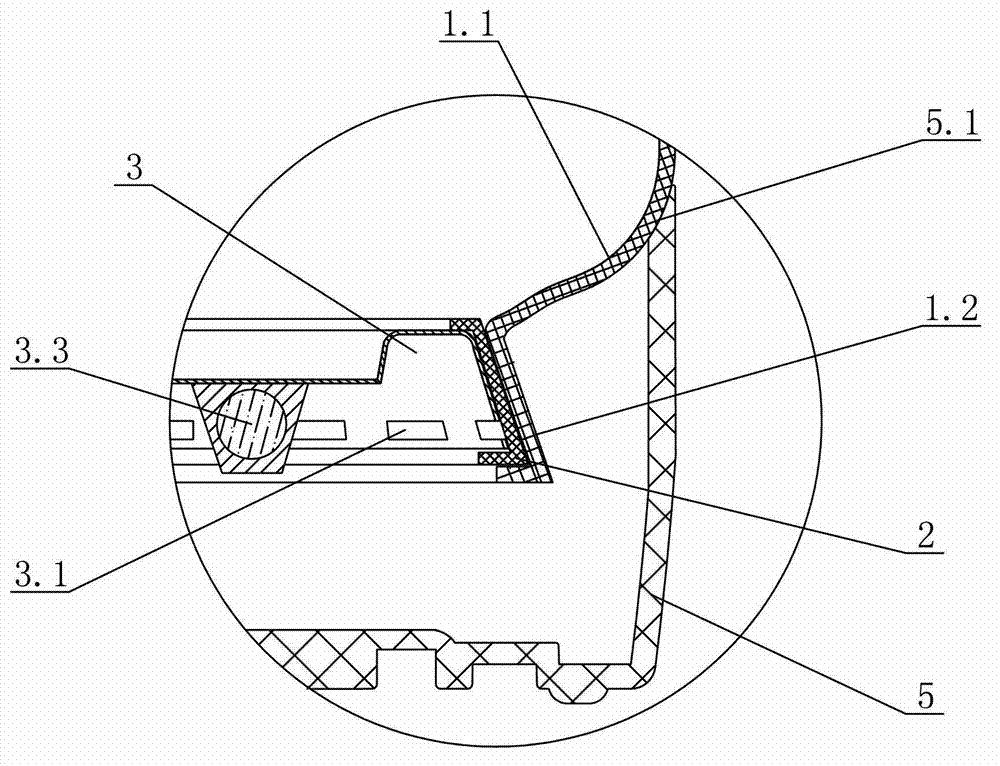

[0042] see Figure 1-Figure 3, an electric heating glass kettle, comprising a glass kettle body 1, a heating plate 3 and a base 5 arranged at the bottom of the glass kettle body 1, an annular sealing ring 2 and a sealing ring 2 are also provided at the joint between the heating plate 3 and the glass kettle body 1 Made of high temperature resistant, anti-aging elastic silicone. The lower part of the glass jug body 1 is provided with an inwardly curved step portion 1.1 and an inner flange 1.2 connected to the bottom of the step portion 1.1, the heating plate 3 is assembled in the inner flange 1.2, and the base 5 and the heating plate 3 are fixed and wrapped. The bladder is arranged on the outside of the step 1.1. The glass jug body 1 is provided with upper and lower openings, wherein the lower opening of the glass jug body 1 is surrounded by the bottom of its inner flange 1.2, which is in an inclined L-shaped structure; the two sides of the inner flange 1.2 are bonded to the se...

no. 2 example

[0046] see Figure 4 The difference between this embodiment and the first embodiment is that several elastic feet 3.2 are provided on the bottom of the heating plate 3 . The assembly method includes the following steps: 1) Stretch the sealing ring 2, press the heating plate 3 with the upper and lower ends of the circular structure into the sealing ring 2, and seal the elastic foot 3.2 at the bottom of the heating plate 3 with the side of the sealing ring 2 or After being placed into the glass jug body 1, the sealing ring 2 is expanded and sealed to contact with the inner groove of the glass jug body 1; The elastic foot 3.2 expands outward and pushes the stretch sealing ring 2 to cling to the inner wall of the inner flange 1.2 or insert it into the inner wall of the L-shaped corner; 3) Assemble the temperature control connector 4 on the bottom of the heating plate 3; 4) Connect the bearing of the base 5 The support part 5.1 fits on the outer side of the step part 1.1 of the gl...

no. 3 example

[0048] see Figure 5 The difference between this embodiment and the first embodiment is that an expansion ring 6 is installed between the heating disk 3 and the sealing ring 2 . The assembly method includes the following steps: 1) Stretch the sealing ring 2, press the heating plate 3 with the upper and lower ends of the circular structure into the sealing ring 2; The expansion ring 6 is embedded and assembled between the sealing rings 2; the expansion ring 6 is squeezed to the outer sealing ring 2 and the heating plate 3 when expanding, so that the sealing ring 2 expands outward; 3) Gently bend the above components, The strong pressure deformation is placed in the inner flange 1.2 of the glass pot body 1, and the expansion ring 6 expands outwards to push the tensile sealing ring 2 to cling to the inner wall of the inner flange side or insert the inner wall of the L-shaped corner; 4) Assemble at the bottom of the heating plate 3 Upper temperature control connector 4; 5) Fit th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com