Hydrodynamic retarder and method for operating a hydrodynamic retarder

A technology of hydraulic reducer and reducer, which is applied in the field of hydraulic reducer, can solve problems such as inability to monitor the reducer, and achieve the effect of simple structure, simple replacement and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

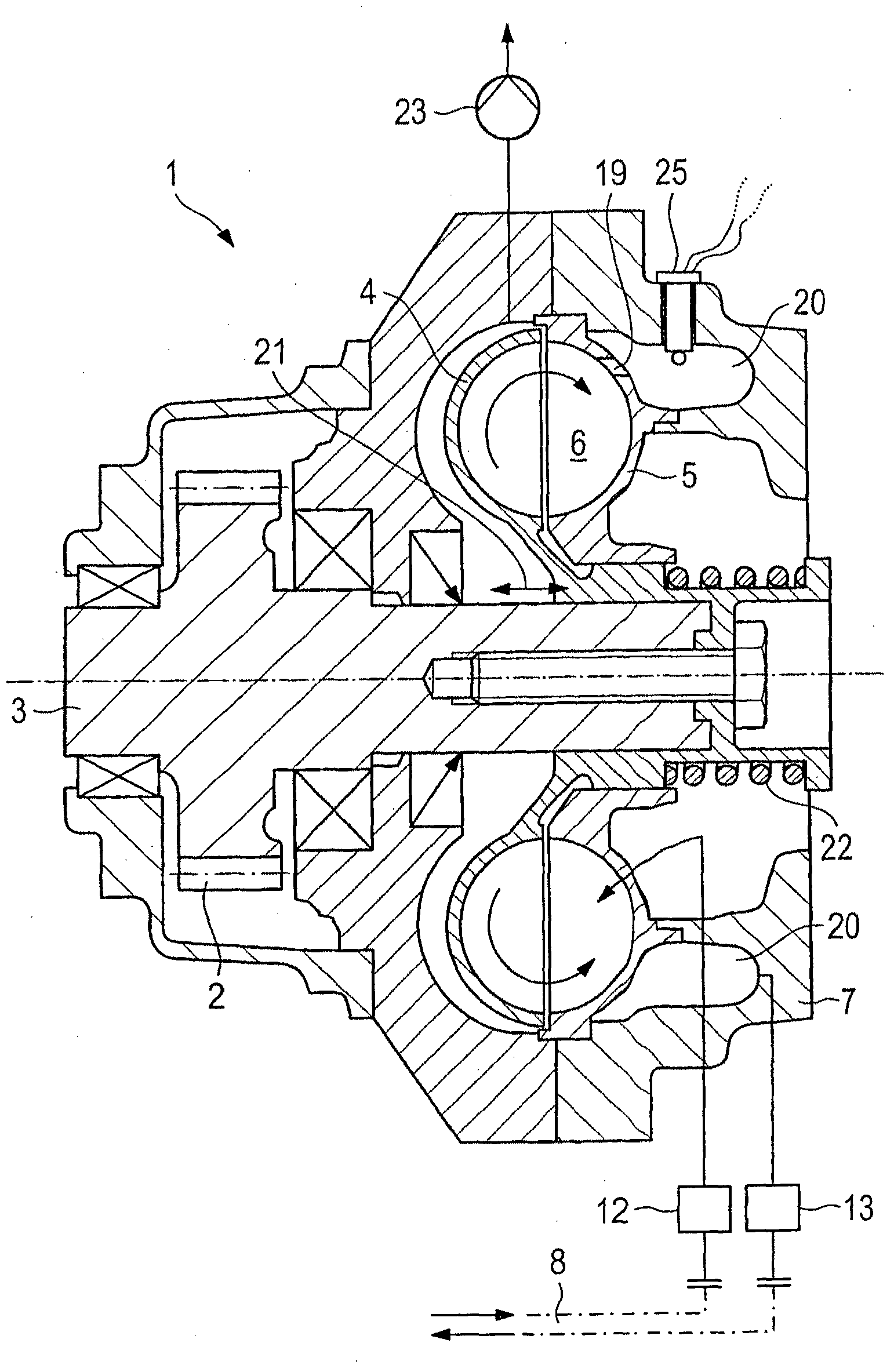

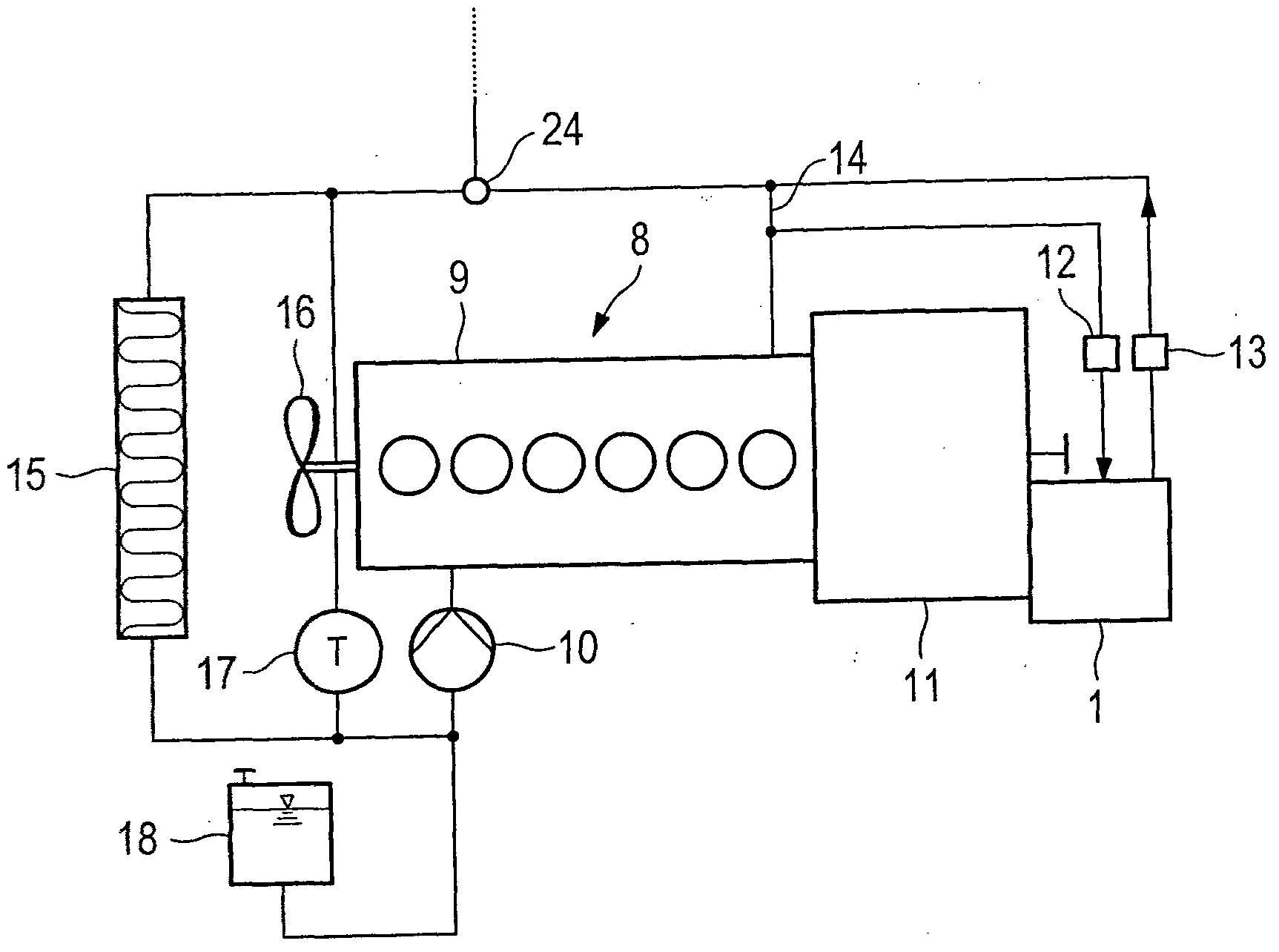

[0019] exist figure 1 The hydraulic retarder 1 can be identified in the description of . For example, it should be designed as a water retarder and be operated with cooling water of the drive train in commercial vehicles as the working medium. The hydrodynamic reducer 1 is driven by the pinion 2 and the shaft 3, the shaft and the pinion are designed as one piece or the pinion 2 is mounted on it accordingly. The pinion 2 can in this case mesh with a corresponding corresponding pinion, in particular on an auxiliary drive of the transmission or the like. The reducer 1 is therefore designed as a secondary water reducer. This structure is understood here purely as an example. The gear unit can be operated quite well with other operating media, such as oil or other suitable materials or material mixtures. This configuration can also be understood purely as a secondary reduction gear. The reduction gear can also be integrated in the transmission or be designed as an embedded red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com