Force-increasing test apparatus for tensile strength of pull rod

A technology of tensile strength and testing equipment, which is applied in the direction of applying repeated force/pulsation force to test the strength of materials, etc., can solve the problem of not being able to judge the thread of the tie rod, and achieve the effects of size reduction, easy operation, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

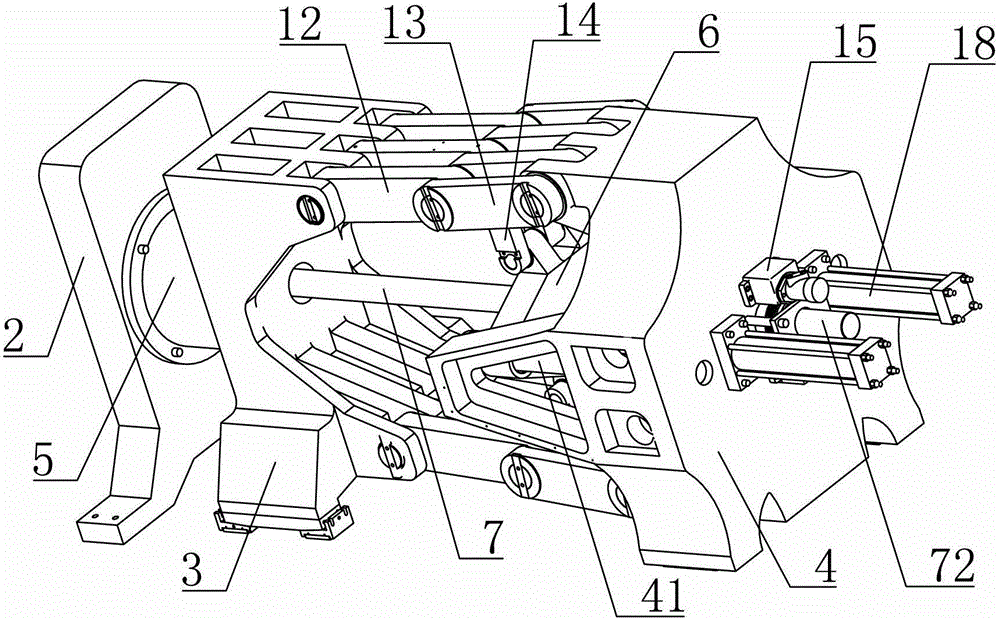

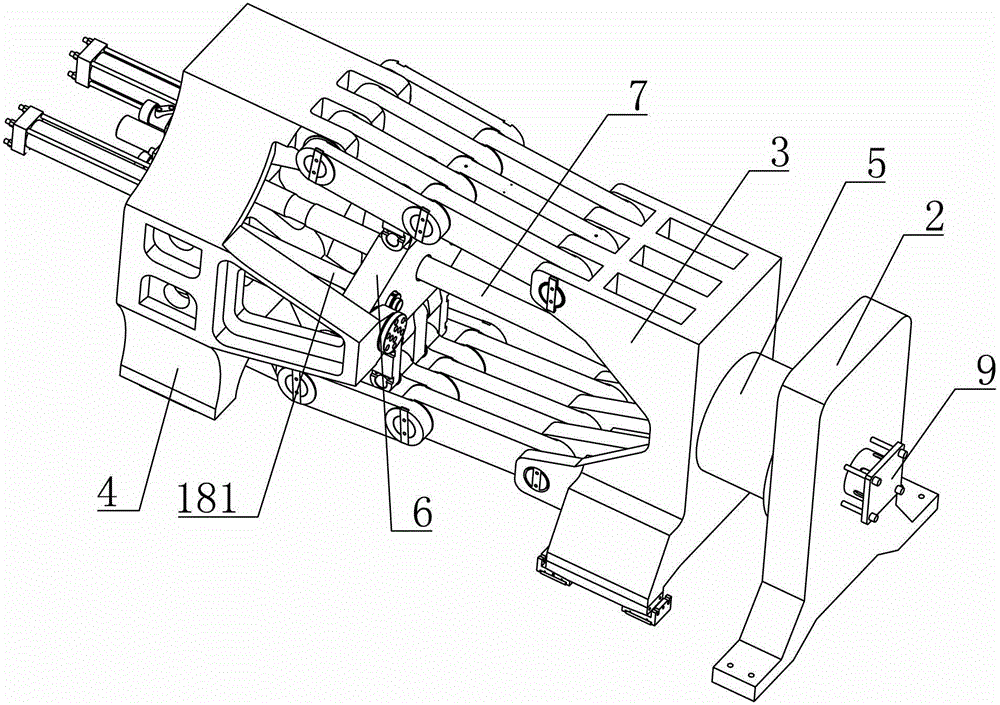

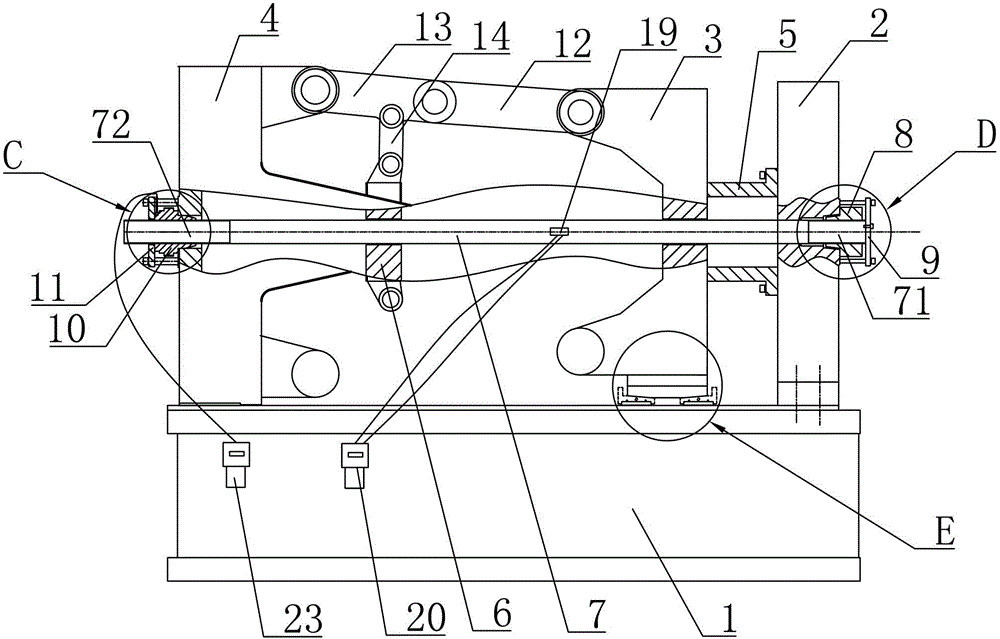

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0024] As shown in the figure, a device for testing the tensile strength of a booster pull rod includes a base 1 and a front plate 2, a middle plate 3 and a rear plate 4 arranged side by side on the base 1 in sequence. The front plate 2 and the base 1 Fixedly connected, the bottom of the middle plate 3 is provided with a sliding assembly 21, the sliding assembly 21 is horizontally slidingly matched with the base 1, the rear plate 4 is horizontally slidingly matched with the base 1, and the front plate 2 is fixedly provided with a The moving limit block 5 is provided with a thrust seat 6 between the rear plate 4 and the middle plate 3, and a thrust seat guide rod 41 is fixedly arranged on the rear plate 4 along the horizontal direction, and the thrust seat 6 is sleeved on the thrust seat guide rod 41 And with its horizontal sliding cooperation,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com