Inspection device for excircle boss height difference of thin-wall rotation-type part

A technology of thin-wall rotation and height difference, which is applied in the direction of measuring devices, instruments, and mechanical devices, can solve the problems of unstable measurement, affecting measurement accuracy, and long measurement time, so as to reduce labor intensity and operation difficulty, and improve detection The effect of efficiency and convenience of the detection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

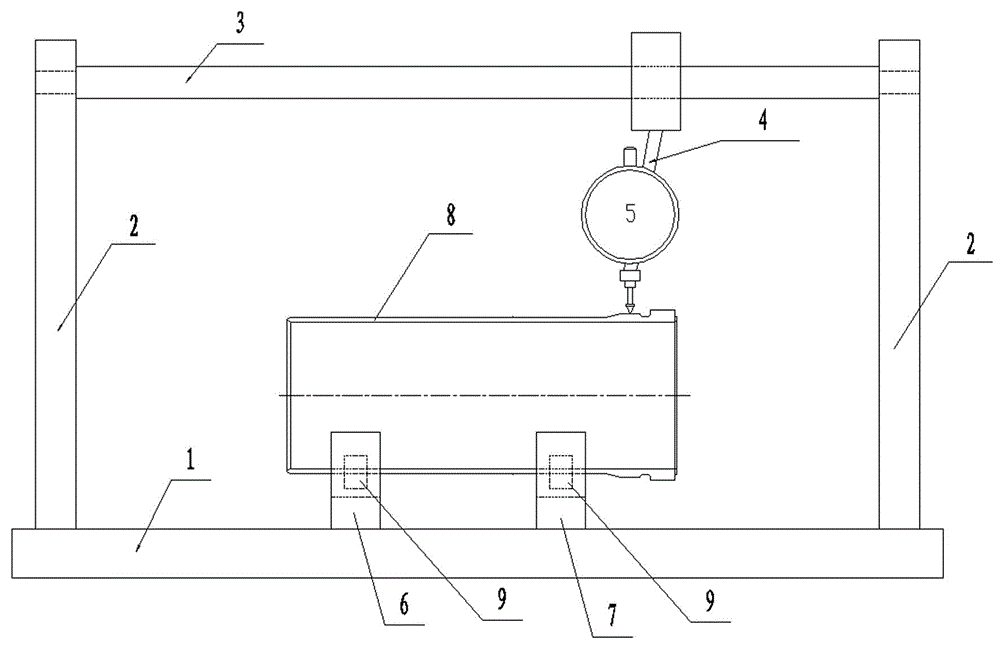

[0010] Example: such as figure 1 As shown in the figure, a measuring tool for the height difference of the outer circular boss of a thin-walled rotary part includes a bottom plate 1, on which two uprights 2 are arranged, and a horizontal bar parallel to the bottom plate 1 is arranged between the upper ends of the two uprights 2 3. There is a fixed bracket 4 on the cross bar 3, and a dial indicator 5 is connected to the bottom of the fixed bracket 4. On the bottom plate 1 below the dial indicator 5, there are two same places for placing parts 8 along the direction of the cross bar 3. V-blocks 6,7. Between the bottom plate 1 and the column 2, between the column 2 and the cross bar 3, between the cross bar 3 and the fixed bracket 4, and between the fixed bracket 4 and the dial indicator 5 are all fixed by bolts. A hard wear-resistant block 9 is provided on the V-shaped blocks 6 and 7 at the position in contact with the part 8. The hard wear-resistant block 9 has a higher hardnes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com