Electronic intelligent controller, control method and air compressor applying controller

An intelligent controller and air compressor technology, applied in pump control, machine/engine, mechanical equipment, etc., can solve problems such as compressor lubrication, deterioration of sealing conditions, impact on the service life of the air compressor, damage to the air compressor, etc. Achieve the effects of reducing energy consumption, eliminating emulsification of lubricating oil, and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

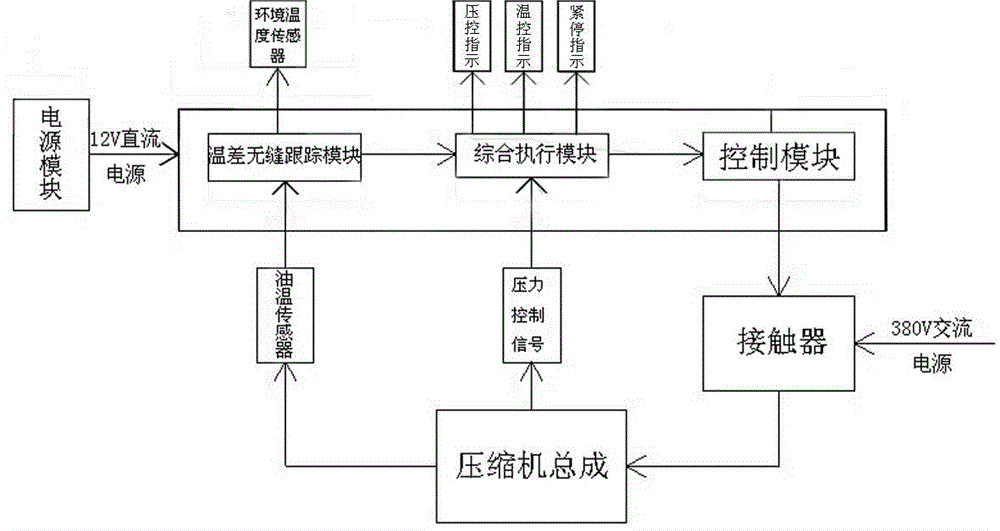

[0027] Such as figure 1 , 2 , 3, and 5, an electronic intelligent controller includes a temperature difference seamless tracking operational amplifier module, a control module and an integrated execution module, and the temperature difference seamless tracking operational amplifier module, the control module and the integrated execution module perform signal transmission in sequence, and the temperature difference The seamless tracking module is integrated by anti-jamming shaping impedance transformation, the control module is integrated by calculation and analysis control output, the comprehensive execution module includes execution integration, and the electronic intelligent controller also includes a working power supply module that provides electric energy.

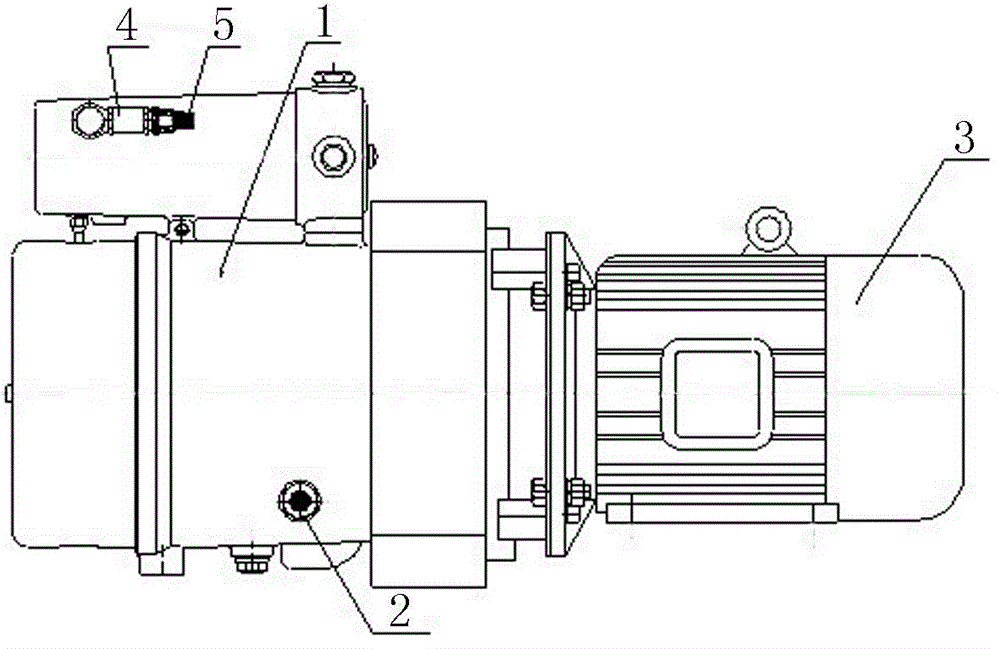

[0028] An air compressor using an electronic intelligent controller includes an air compressor body 1 and a motor 3, the air compressor body is connected to the motor 3, and the air compressor also includes an oil tem...

Embodiment 2

[0045] Such as image 3 , 4 As shown, under different conditions, the relationship between the ambient temperature and the real-time dew point temperature, according to the measured ambient temperature, determine the real-time dew point temperature, the method is as follows:

[0046] Set the environmental conditions of the electronic intelligent controller to the following conditions, the absolute working pressure is 0.95MPa, the absolute atmospheric pressure (intake pressure) is 0.1MPa, p2 / p1=9.5, and the air humidity is 60%: when the ambient temperature is 10 ℃, the electronic intelligent controller determines that the real-time dew point temperature is 39 ℃; when the ambient temperature is 15 ℃, the electronic intelligent controller determines that the real-time dew point temperature is 45.5 ℃; when the ambient temperature is 20 ℃, the electronic intelligent controller determines the real-time dew point The temperature is 52°C; when the ambient temperature is 25°C, the ele...

Embodiment 3

[0050] Such as image 3 , 4 As shown, under different conditions, the relationship between the ambient temperature and the real-time dew point temperature, according to the measured ambient temperature, determine the real-time dew point temperature, the method is as follows:

[0051] Set the environmental conditions of the electronic intelligent controller to the following conditions, the absolute working pressure is 0.95MPa, the absolute atmospheric pressure (intake pressure) is 0.1MPa, p2 / p1=9.5, and the air humidity is 90%: when the ambient temperature is 10 ℃, the electronic intelligent controller determines that the real-time dew point temperature is 46.5 ℃; when the ambient temperature is 15 ℃, the electronic intelligent controller determines that the real-time dew point temperature is 53 ℃; when the ambient temperature is 20 ℃, the electronic intelligent controller determines the real-time dew point The temperature is 59.75°C; when the ambient temperature is 25°C, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com