Manufacturing method of sludge biomass fuel

A technology of biomass fuel and manufacturing method, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of not meeting energy-saving benefits, high energy consumption, and not an energy model of sustainable development, and achieve economical and practical processing capacity, easy burning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

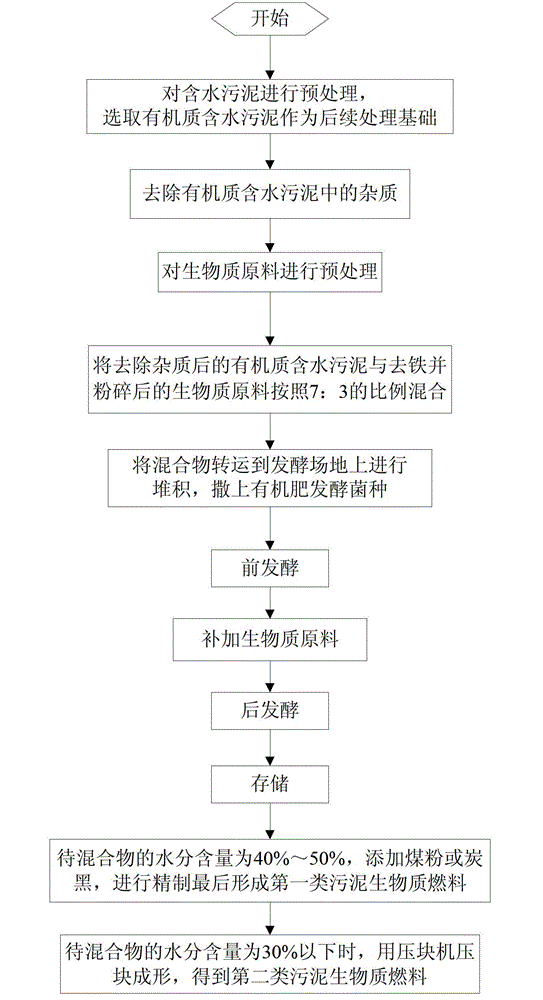

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0023] like figure 1 The manufacture method of shown sludge biomass fuel, it may further comprise the steps:

[0024] Step 1. Pretreatment of water-containing sludge: According to the nature and treatment method of sludge, water-containing sludge is divided into inorganic water-containing sludge and organic matter water-containing sludge as the basis for subsequent treatment; generally, biochemical methods are used to treat water-containing sludge Most of the domestic sludge is organic sludge, which can be used as fuel; while a considerable part of the industrial sludge treated with acid and alkali is inorganic sludge. This kind of industrial sludge is simply squeezed and the pH is adjusted to 6-7. It can also be classified as organic hydrous sludge, waiting for subsequent treatment;

[0025] Step 2. Remove impurities in the organic water-co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com