Luminous stereoscopic dial assembly structure of automobile

A component structure and dial technology, which is applied in vehicle parts, transportation and packaging, etc., can solve the problems that the flat surface plate cannot realize the 3D surface effect, the outline of the 3D effect of the 3D surface plate is not clear, and the price of the 3D surface plate is high. , to achieve the effect of novel dial, clearer outline and better effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

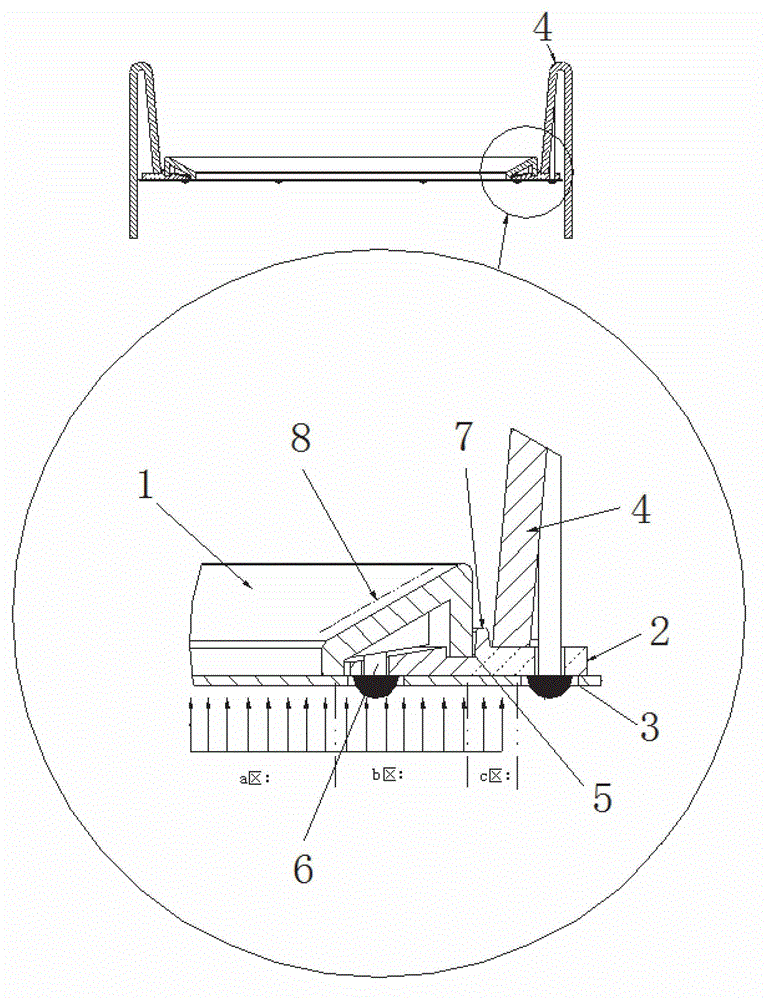

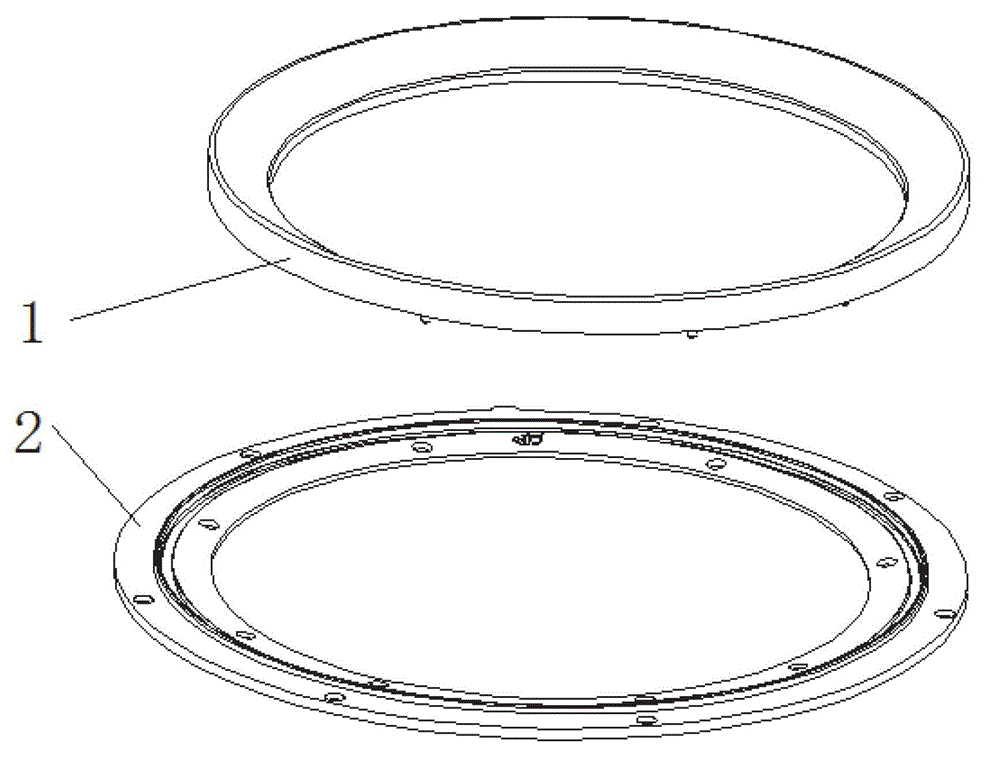

[0015] like Figure 1~Figure 2 A luminous three-dimensional automobile dial assembly structure is shown, including dial 1, aperture 2, watch plate 3, instrument front frame 4, aperture 2 is provided with card slot 5 and hot riveting holes, and the outer wall of the edge of dial 1 is provided. The bottom is snapped into the card slot 5 , the dial 1 is provided with a hot riveting column 6 which passes through the hot riveting hole and is fixed by hot riveting, and the watch plate 3 is arranged close to the aperture 2 . The dial corresponding to the display surface 8 of the dial 1 is transparent. The aperture 2 protrudes with a protrusion 7 placed beside the card slot 5, and the outer wall of the watch plate corresponding to the protrusion 7 is provided with a color coating. The front frame 4 of the instrument is fixed with the aperture 2 by heat riveting. The display surface 8 of the dial 1 is provided with a transparent scale. Aperture 2 is a transparent aperture. It is no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com