Automatic paper mask production machine

A production machine, fully automatic technology, applied in clothing, clothing, protective clothing, etc., can solve the problems of unable to meet production needs, cumbersome mask production process, high labor cost, achieve significant social and economic benefits, and reduce labor intensity of workers , the effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

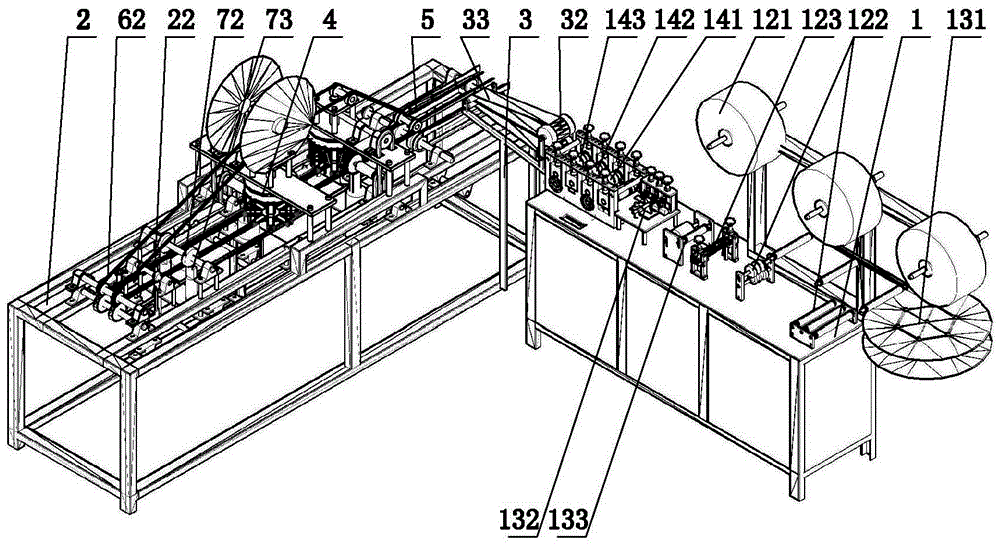

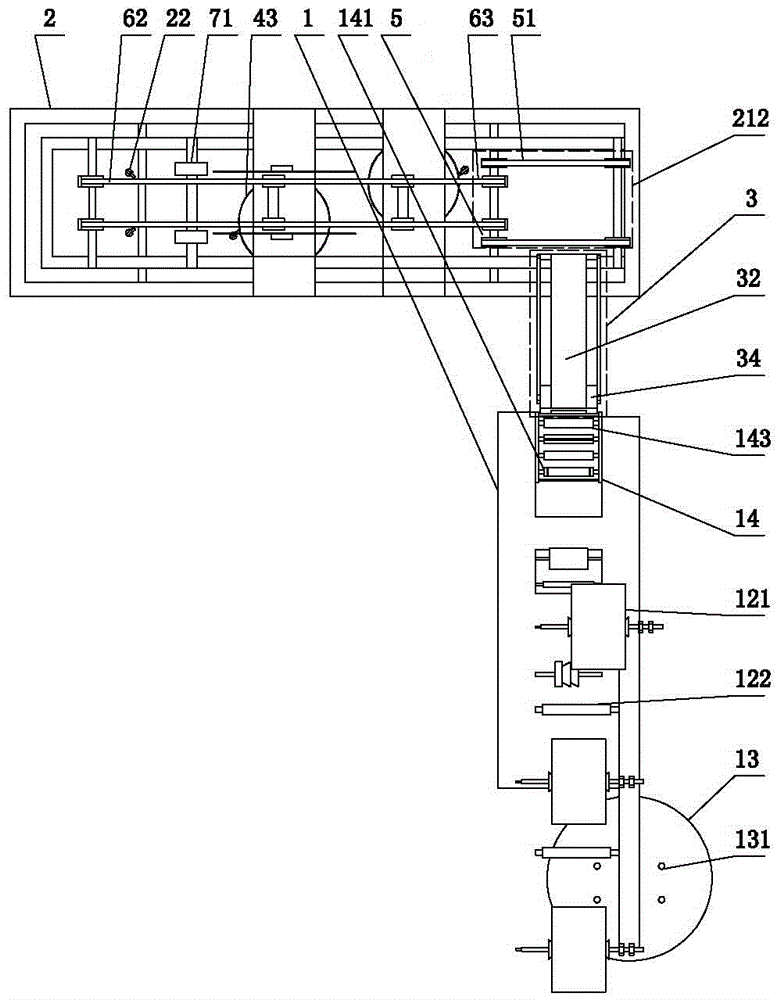

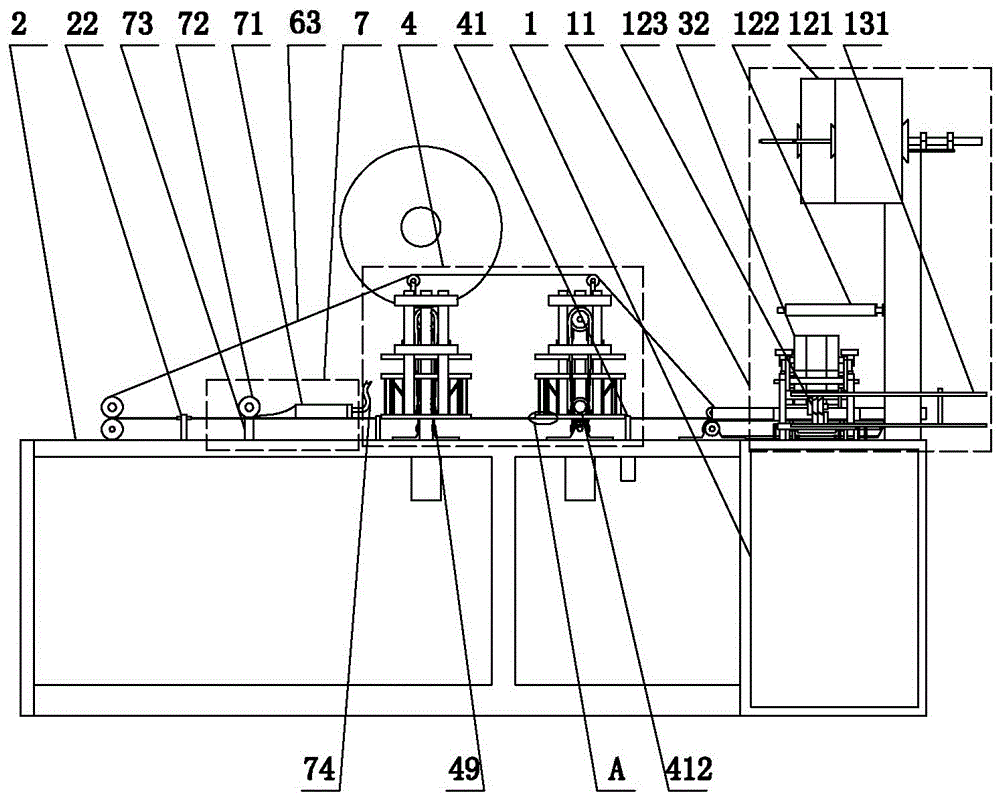

[0021] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0022] see figure 1 , 2 , 3, 4, 5, 6, 7, 8. As can be seen from the figure, the fully automatic paper mask production machine is mainly composed of a motor, a mask punching machine 1 for forming mask pieces, an ear strap sticking machine 2 for making paper masks, and a mask piece clamping device 3. The mask punching machine 1 includes a frame top and is provided with a mask paper conveying device 12, a bridge of the nose conveying device 13, and a welding and cutting device 14 in sequence. Mask paper conveying device 12 comprises mask paper support 121, mask paper guide wheel 122, mask paper folding steel sheet 123, wherein mask paper support 121 is positioned at the frame top, and mask paper support 121 bottom is provided with mask paper guide wheel group 122, mask paper The left side of guide wheel grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com