Lamp base of anti-explosion fluorescent lamp fitting

A technology for lamp pins and lamps, which is applied to the anti-damage measures of lighting devices, lighting devices, parts of lighting devices, etc., and can solve the problems of unsightly appearance, protruding ribs are easy to get stuck on cross holes, springs are easy to rust and damage, etc. problems, achieve good self-installation performance, ensure initial installation efficiency, and prevent rust damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

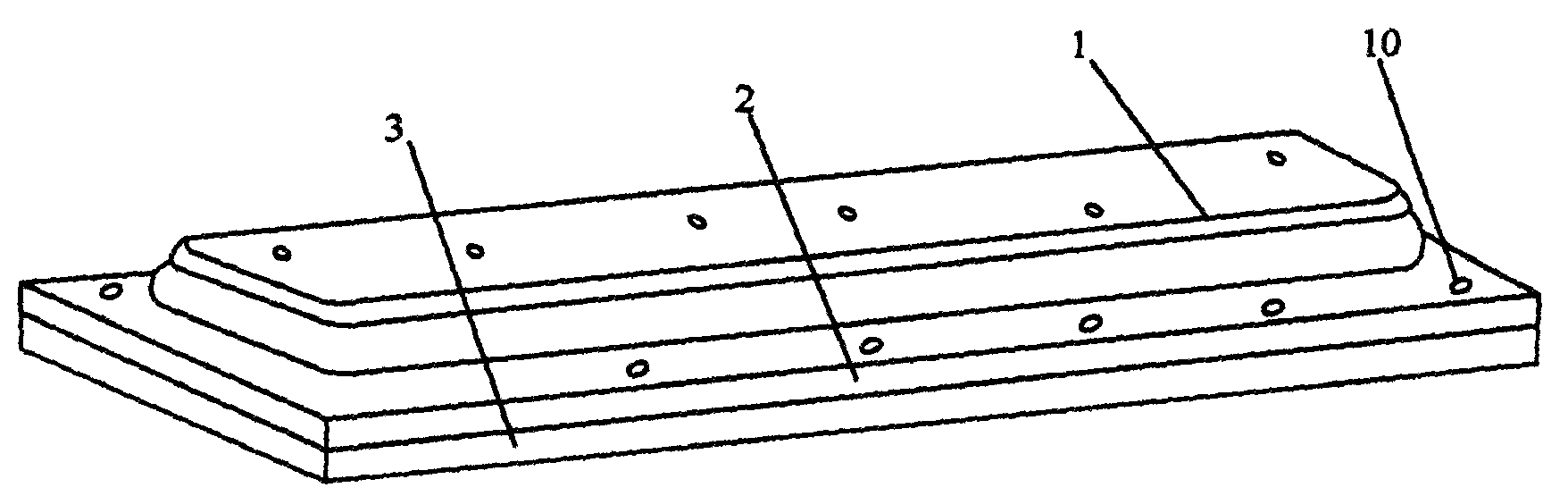

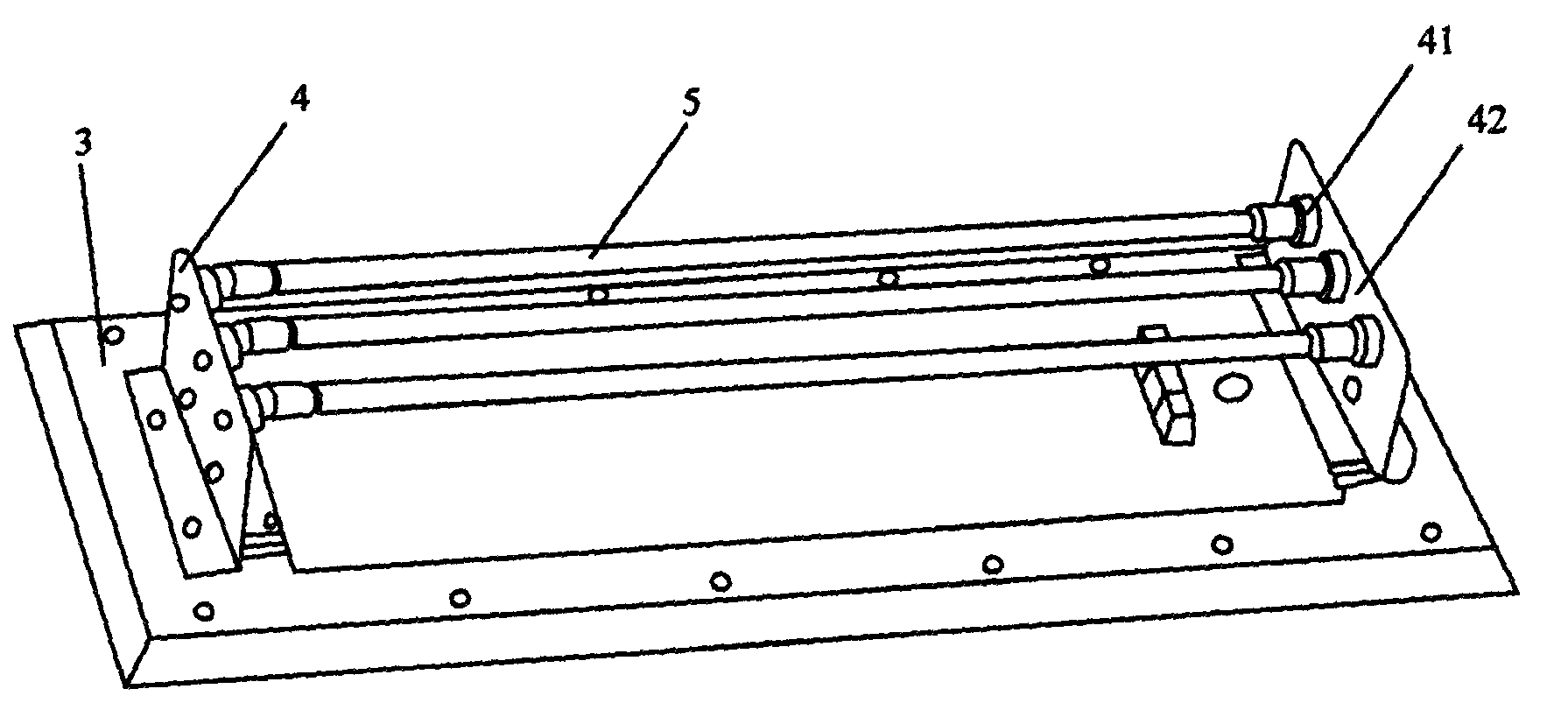

[0036] like figure 1 , figure 2 , an explosion-proof fluorescent lamp, including a lampshade 1, a lamp cover 2 and a base 3 that are detachably connected in sequence, a lamp holder (omitted in the figure) is arranged on both sides of the base 3, and a lamp foot 4 is arranged on the lamp holder.

[0037] At least one explosion-proof lamp tube 5 installed on the lamp pin 4, usually three.

[0038] A reflector (omitted in the figure) is arranged between the base 3 and the explosion-proof lamp tube 5 . The lampshade 1, the lamp cover 2, the base 3 and the reflector are all provided with a plurality of connecting pieces 10 for installation, and the connecting pieces 10 are commonly used with screws, bolts and the like. Electrical components such as ballasts are placed in the gap between the reflector and the base 3 .

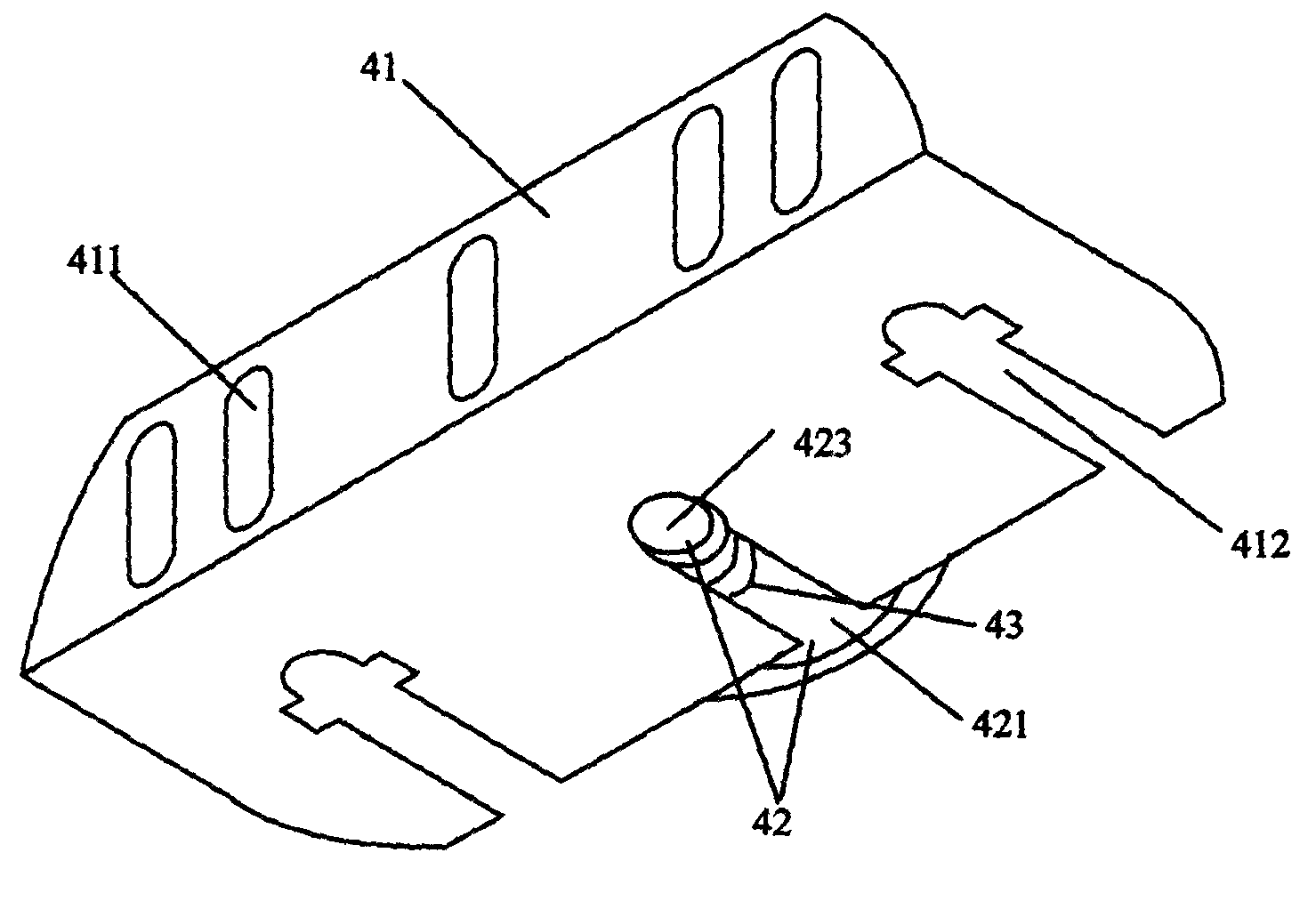

[0039] like Image 6 , Figure 7 The lamp pin of the explosion-proof fluorescent lamp of the present invention includes a lamp base 41 connected to the lamp fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com