Anti-blocking bubbler

A bubbler and anti-blocking technology, which is applied in indoor sanitary pipeline installations, water supply installations, buildings, etc., can solve the problems of high production cost, easy generation of scale, and blockage, etc., so as to improve the convenience and comfort of water use, Strong deformation ability and good control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

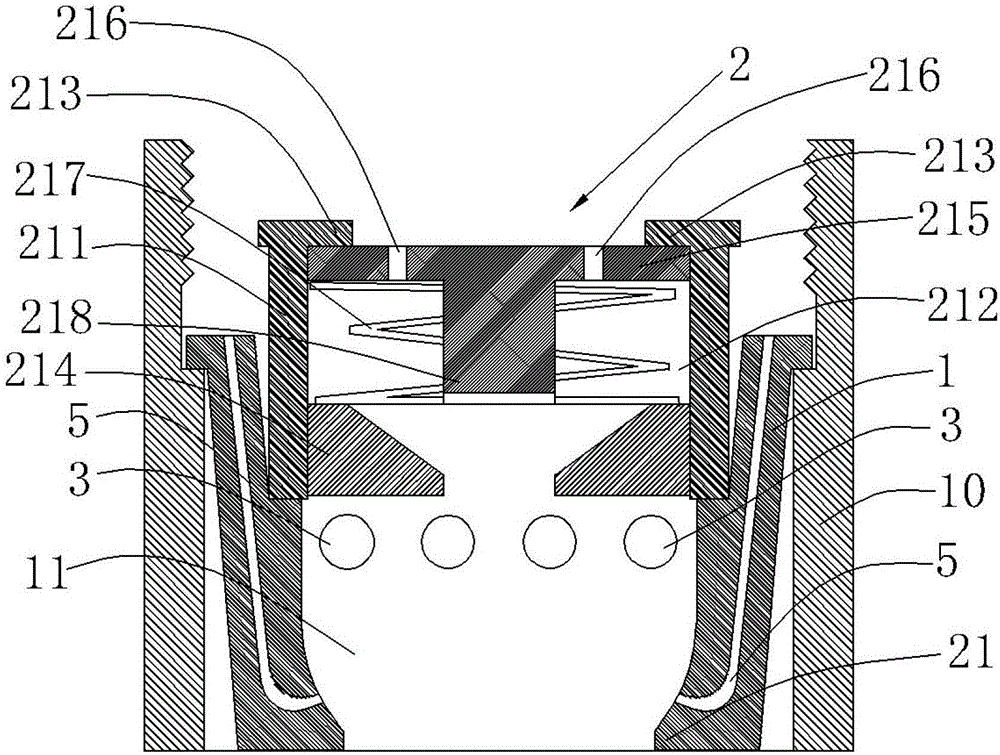

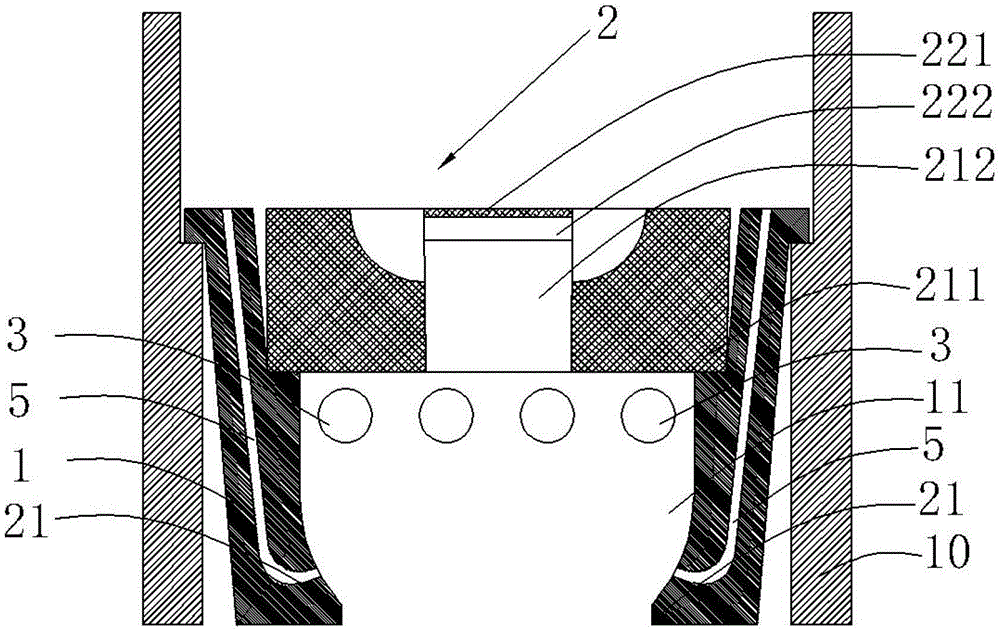

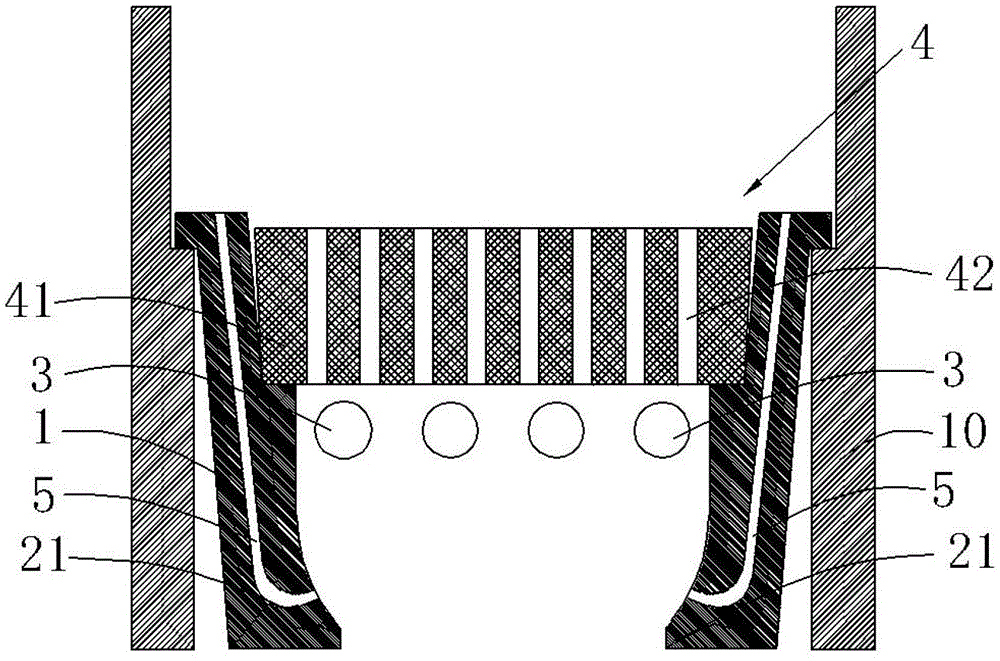

[0021] The present invention will be further elaborated below in conjunction with accompanying drawing, wherein, the direction of the present invention is with figure 1 as standard.

[0022] Such as figure 1 and figure 2 As shown, the anti-blocking bubbler of the present invention includes a valve body 1, an atomizing device 2, at least one air inlet 3 and a water retaining part 21. The valve body 1 is installed at the water outlet end of the water outlet terminal 10, and the valve body 1 forms a There is a longitudinal (upper and lower ends) through the water channel 11, the atomization device 2 is set at the water inlet end of the water channel 11, the ring-shaped water retaining part 21 is set at the water outlet of the water channel 11, and all the air inlets 3 Distributed on the side wall of the valve body 1 in the radial direction, and communicate with the water passages 11 respectively, all the air inlets 3 are located between the atomizing device 2 and the water ret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com