Preparation technique of iron ore pellets

A preparation process and a technology for iron ore pellets, applied in the field of preparation technology of iron ore pellets, can solve the problems of difficulty in fully expanding montmorillonite, short expansion time, and difficulty in functioning, and improve the quality of green pellets, improve strength, The effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

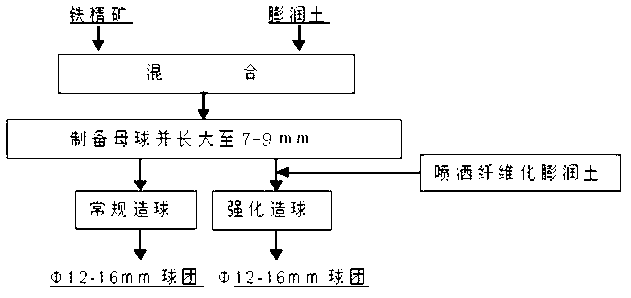

Method used

Image

Examples

Embodiment 1

[0038]Example 1: The ratio of bentonite, water, and CMC is 100:500:2 to prepare fibrous bentonite. When the total amount of bentonite is 1.1% (the amount of pre-prepared bentonite is 1.0%) to strengthen the ball, the compression resistance of the raw ball The strength, drop strength and burst temperature are 14.1N / piece, 3.4 times / 0.5m and 540°C, respectively, and the compressive strengths of the preheated balls and roasted balls obtained by preheating at 900°C for 15 minutes and roasting at 1280°C for 10 minutes are 408N / and 2700N / piece.

Embodiment 2

[0039] Example 2: The ratio of bentonite, water, and CMC is: 100:500:2 to prepare fibrous bentonite. When the total amount of bentonite is 1.25% (the amount of pre-prepared bentonite is 1.0%) to strengthen the pelletization, the compression resistance of the raw ball The strength, drop strength and burst temperature are 13.4N / piece, 4.4 times / 0.5m and 548°C respectively, and the compressive strengths of preheated balls and roasted balls obtained by preheating at 900°C for 15 minutes and roasting at 1280°C for 10 minutes are respectively 538N / and 3100N / piece.

Embodiment 3

[0040] Example 3: The ratio of bentonite, water, and CMC is: 100:500:2 to prepare fibrous bentonite. When the total amount of bentonite is 0.77% (the amount of pre-prepared bentonite is 0.5%) to strengthen the pelletization, the compression resistance of the raw ball The strength, drop strength and burst temperature are 10.4N / piece, 2.9 times / 0.5m and 590°C respectively, and the compressive strengths of preheated balls and roasted balls obtained by preheating at 900°C for 15 minutes and roasting at 1280°C for 10 minutes are respectively 359N / and 2530N / piece.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com