A Complementary Fault-Tolerant Linear Motor

A linear motor and complementary technology, applied in the field of motor manufacturing and linear drive, can solve the problems of reducing the power density of the motor and occupying the slot space, and achieve the effect of reducing the positioning force, convenient embedding and high fault tolerance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings.

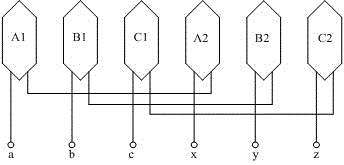

[0028] In order to explain the structural features and beneficial effects of the linear motor of the present invention more simply and clearly, a detailed description will be given below in conjunction with a specific three-phase motor.

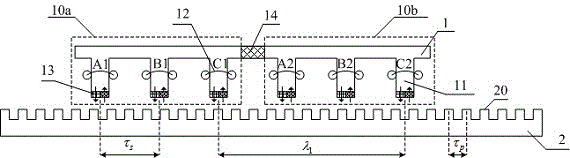

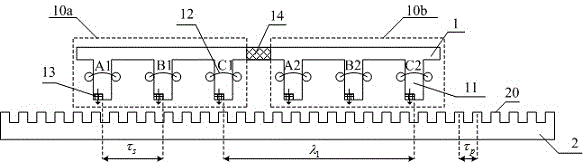

[0029] Such as figure 1 The shown primary permanent magnet linear motor of the present invention includes a primary 1 and a secondary 2 with a salient pole structure. There is an air gap between the primary 1 and the secondary 2, wherein the primary 1 is composed of a module 10a and a module 10b made of a magnetically permeable material, and the two modules are connected by a magnetically permeable material 14 . The primary 1 includes armature teeth 11, each armature tooth 11 is wound with a set of concentrated winding coils 12, and two permanent magnets 13 with opposite polarities are fixed on the ends of the armature teeth 11 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com