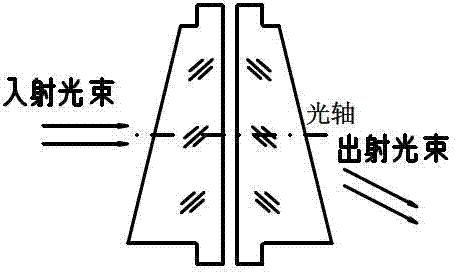

Light beam scanning mechanism based on rotation double wedge lenses

A technology of beam scanning and wedge mirror, which is applied in optics, optical components, instruments, etc., can solve the problems of not being able to satisfy large-aperture scanning and the size of the optical wedge mirror cannot be enlarged, and achieve simple and reliable connection relationship and flexible and convenient shaft adjustment , small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the drawings and embodiments.

[0029] The invention provides a beam scanning mechanism based on a rotating double wedge mirror, such as Picture 9 As shown, the beam scanning mechanism includes two sets of optical components, and the two sets of optical components have the same installation method. The structure of one optical component is taken as an example below. The optical assembly includes an optical wedge mirror 1, a frame 2, a large gear 3, a small gear 4, a motor 5, a bearing 6, a bracket 7 and an angle measuring code plate 8. The optical wedge mirror 1 is installed inside the frame 2, The mirror frame 2 is mounted on the bracket 7 through the bearing 6. The mirror frame 2 is cylindrical, and one end surface is equipped with an angle measuring code plate 8 for measuring the rotation speed of the wedge mirror 1, and the other end surface is equipped with a large gear 3. Used for gear trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com