Special tools for zinc oxide arrester test

A special tool and lightning arrester technology, which is applied in the direction of the measuring device shell, etc., can solve the problems of fatigue work, low work efficiency, and small safety factor of test personnel, and achieve the effect of reducing the time of repeated tests, improving the safety factor of grounding, and firm grounding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

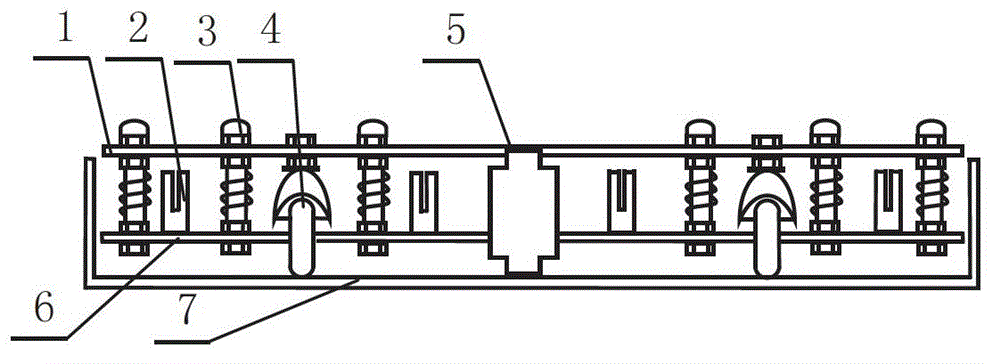

[0014] Such as figure 1 , 2 As shown, the present invention includes an upper disc 1, a lower disc 6, a tray 7 and the like.

[0015] A connecting piece 3 and a runner 4 are arranged between the upper disc 1 and the lower disc 6 . The connecting piece 3 is a bolt and nut structure, which is used to connect and fix the upper disc 1 and the lower disc 6 as a whole. Described runner 4 is universal wheel, can assist upper disk 1, lower disk 6 to rotate on pallet 7; The upper and lower discs 6 have larger holes, which are convenient for the runner 4 to rotate.

[0016] A rotating part connecting the upper disc 1 and the lower disc 6 is set at the middle position of the tray 7, so that the upper disc 1 and the lower disc 6 can be rotated on the tray 7. The rotating part 5 is a bearing.

[0017] On the lower disc 6, some snap rings 2 that can be inserted into the lightn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com