Detection device for detecting form and location tolerance of irregular structure

A detection device, shape and position tolerance technology, applied in the direction of measuring devices, mechanical devices, mechanical measuring devices, etc., can solve the problems of irregular structural shape in local areas, lack of universal practicability, complicated operation process, etc., and achieve the determination method Easy to understand, simple structure, and the effect of improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

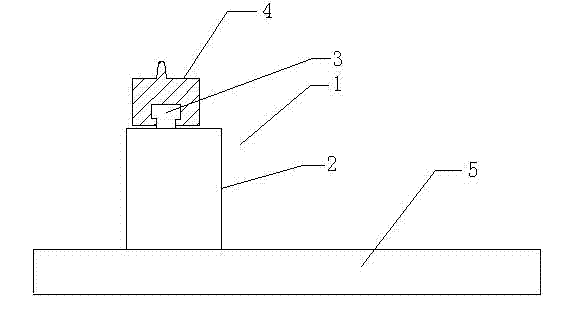

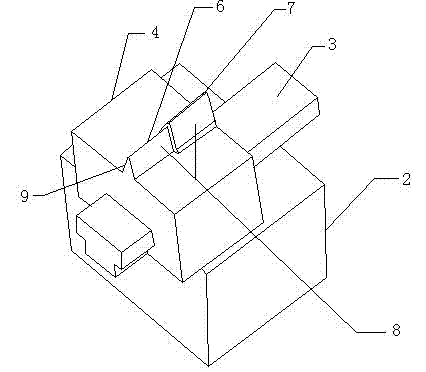

[0016] Such as figure 1 and 2 As shown, it is a detection device for detecting the shape and position tolerance of irregular structures, including a bottom plate 5 and a detection part 1, wherein the detection part 1 is composed of a support block 2, a slide rail 3 and a detection block 4, and the detection part 1 is supported by The block 2 is fixedly installed on the bottom plate 5, the slide rail 3 is fixedly installed on the support block 2, the detection block 4 can be provided with a card slot matching with the slide rail 3, and the detection block 4 can be installed on the slide rail 3 through the card slot , and slide along the slide rail 3 axially and horizontally; the detection surface 8 of the detection block 4 is the same as the detected structure profile, and the working part 9 of the detection surface 8 is a through-stop structure, and the through-stop structure is composed of the through end 6 and the The size of the through end 6 is the size of the detected st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com