Front conveying and lifting transferring system for processing straw

A technology of straw and conveyor belt, which is applied in the field of front conveying and lifting transfer system, which can solve the problems of inconvenient use, material jam, and low efficiency, and achieve the effect of improving feeding efficiency, improving overall performance, and ensuring smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

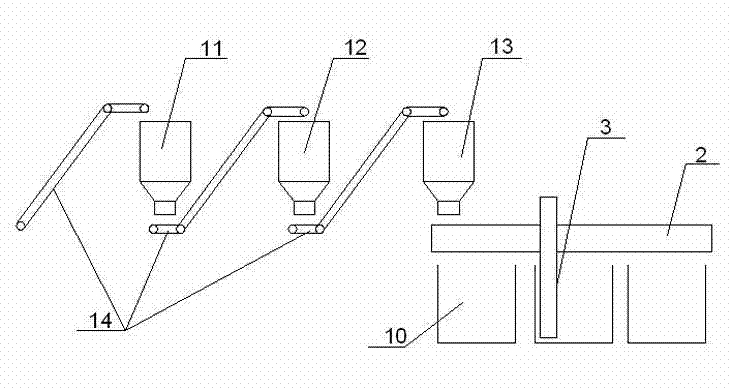

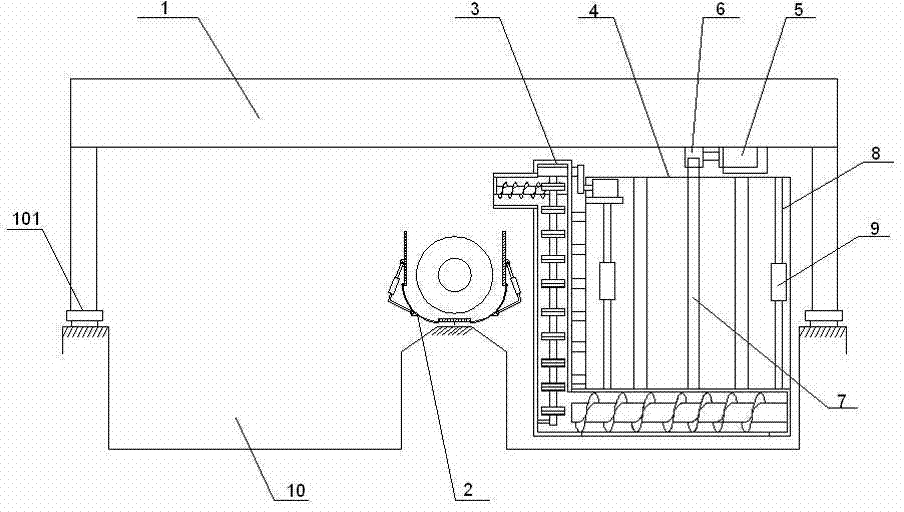

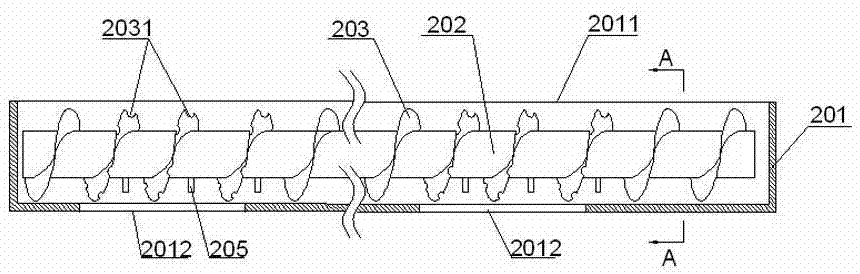

[0030] As shown in the figure, the front conveying and lifting transfer system for processing straw mainly consists of a conveyor belt 14 for conveying straw materials, a crushing mechanism 11, a distribution bin 12, a mixing bin 13, a crushing material conveying device 2, a fermentation The tank 10 and the lifting device used to lift the materials in the fermentation tank to the crushed material conveying device, the crushed material mechanism 11, the distributing bin 12 and the mixing bin 13 are sequentially connected in series through the conveyor belt 14, and the straw material is cut by the crushed material mechanism. The conveyor belt passes through the distribution bin and the mixing bin in turn, and the mixing bin is processed and sent to the crushed material conveying device:

[0031] The lifting device includes a mobile frame 1 across the fermentation tank, a material transfer device 3, a support frame 4 for supporting the material transfer device, and a lifting mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com