In-situ remediation method aiming at dispersible petroleum-contaminated soil

An oil pollution and in-situ remediation technology, applied in the field of environmental engineering, can solve problems such as difficulty in adapting to dispersed oil-contaminated soil remediation, high chemical consumption, and low remediation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

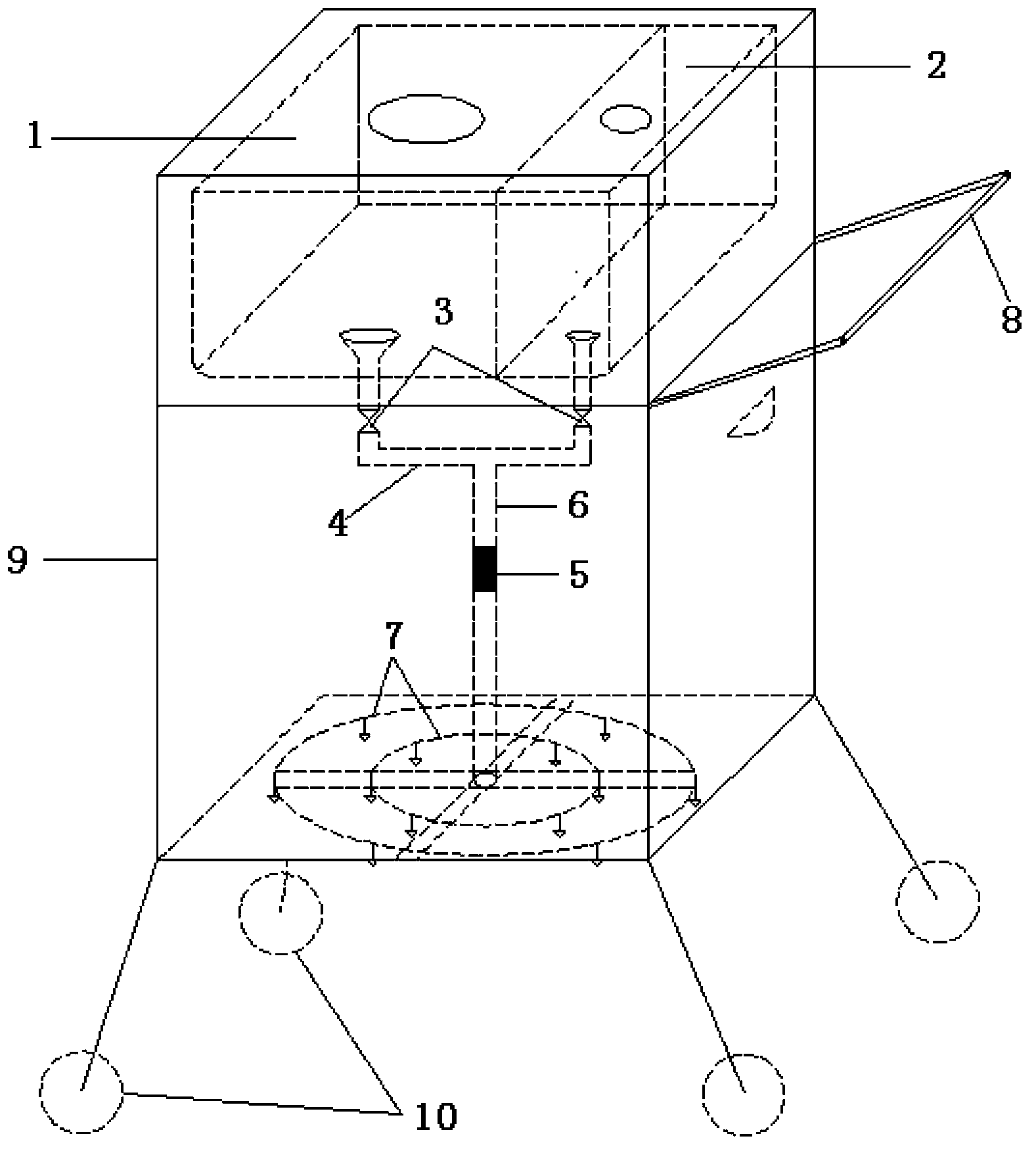

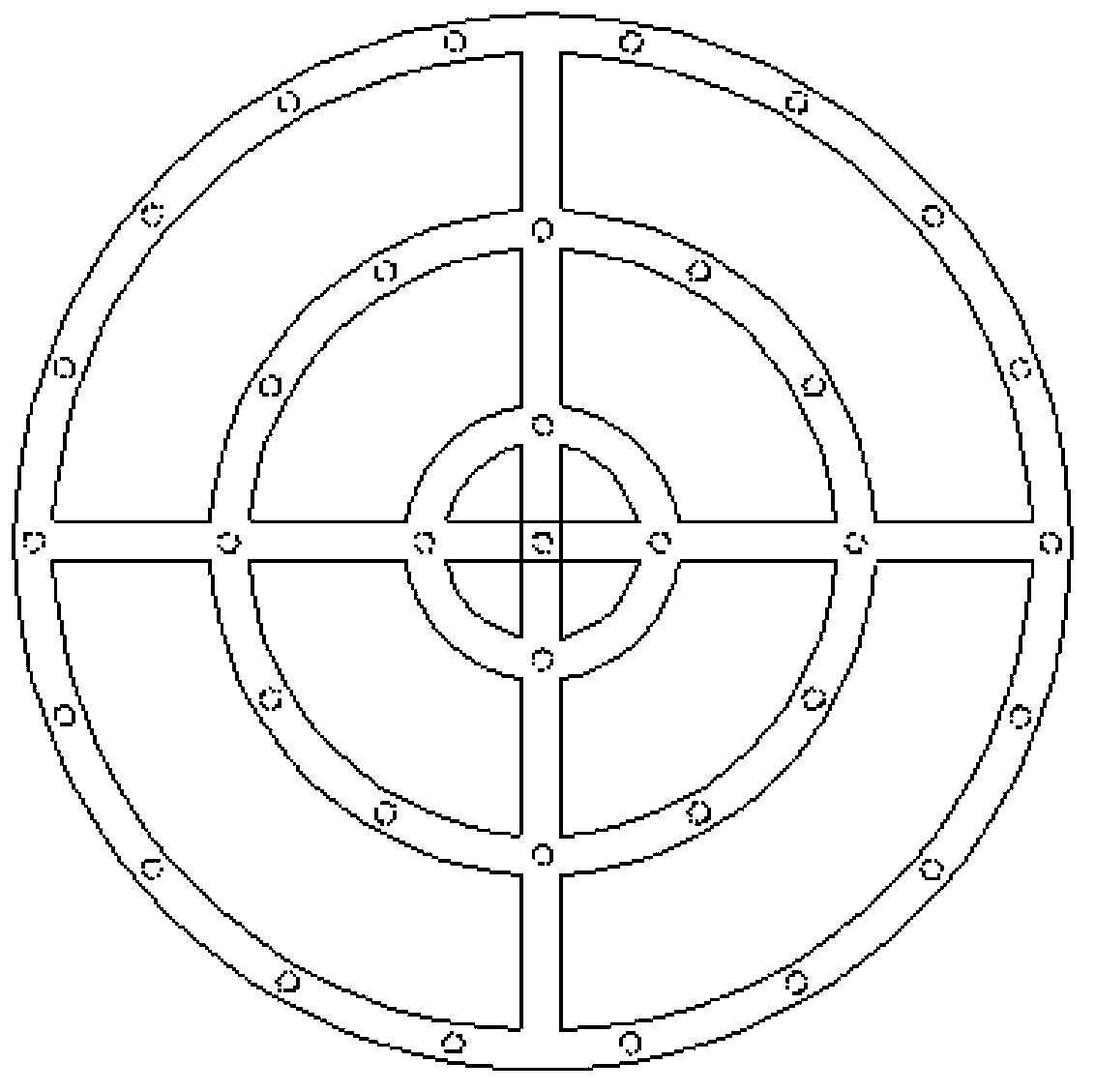

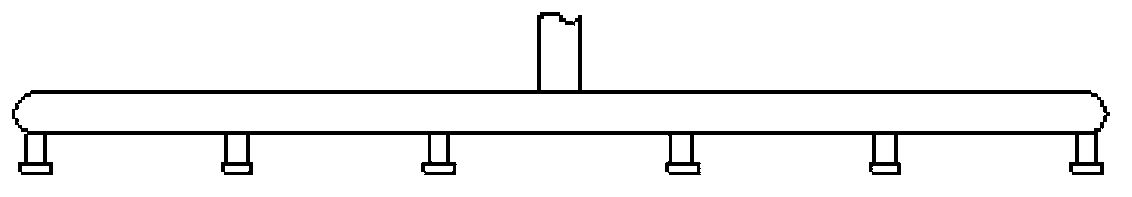

Method used

Image

Examples

Embodiment 1

[0038] Example 1: Restoration of S1 area in lightly polluted area

[0039] After measurement, the area of oil-contaminated soil in the S1 area of the lightly polluted area is 1m 2 , the average depth of pollution is 2cm. After sampling and weighing, the total amount of oil-contaminated soil in the S1 area of the lightly polluted area is 53kg.

[0040] The OCMA-350 non-dispersive infrared petroleum analyzer is used to detect that the average concentration of petroleum hydrocarbons in petroleum-contaminated soil is 14.35g / kg. According to the concentration of petroleum hydrocarbons, it is necessary to configure H with a concentration of 150mmol / L. 2 o 2 . With crosslinking agent citric acid (17.4g / L) and FeSO 4 ·7H 2 O (9.7g / L) is formulated into iron solution, so that Fe in iron solution 2+ The concentration of the iron solution is 69.8mmol / L, and the pH value of the iron solution is adjusted with NaOH before use, so that the oil-contaminated soil remains neutral aft...

Embodiment 2

[0047] Example 2: Restoration of the S2 area in the moderately polluted area

[0048] After measurement, the area of oil-contaminated soil in S2 area of moderately polluted area is 1m 2 , The average depth of pollution is 2cm. After sampling and weighing, the total amount of oil-contaminated soil in the S2 area of the lightly polluted area is 53kg.

[0049] The OCMA-350 non-dispersive infrared petroleum analyzer is used to detect that the average concentration of petroleum hydrocarbons in petroleum-contaminated soil is 23.23g / kg. According to the concentration of petroleum hydrocarbons, it is necessary to configure H with a concentration of 200mmol / L. 2 o 2 . With crosslinking agent citric acid (17.4g / L) and FeSO 4 ·7H 2 O (9.7g / L) is formulated into iron solution, so that Fe in iron solution 2+ The concentration of the iron solution is 69.8mmol / L, and the pH value of the iron solution is adjusted with NaOH before use, so that the oil-contaminated soil remains neutr...

Embodiment 3

[0055] Example 3: Restoration of the heavily polluted area S3 area

[0056] After measurement, the area of oil-contaminated soil in the S3 area of the heavily polluted area is 1m 2 ,, The average depth of pollution is 2cm. After sampling and weighing, the total amount of oil-contaminated soil in the S3 area of the lightly polluted area is 53kg.

[0057] The OCMA-350 non-dispersive infrared petroleum analyzer is used to detect that the average concentration of petroleum hydrocarbons in petroleum-contaminated soil is 95.62g / kg. According to the concentration of petroleum hydrocarbons, it is necessary to configure H with a concentration of 350mmol / L. 2 o 2 . With crosslinking agent citric acid (17.4g / L) and FeSO 4 ·7H 2 O (9.7g / L) is formulated into iron solution, so that Fe in iron solution 2+ The concentration of the iron solution is 69.8mmol / L, and the pH value of the iron solution is adjusted with NaOH before use, so that the oil-contaminated soil remains neutral a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com