Algae factorization circulating aquaculture system

A recirculating aquaculture and factory technology, applied in fish farming, climate change adaptation, application, etc., can solve the problems of lack of limited interception means of solid particles, low utilization of plane space, and low proportion of workshop area, etc. Improve the effect of low ratio of aquaculture water surface area to water treatment water surface area, avoiding water quality decline, and compact workshop layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described below in conjunction with accompanying drawing.

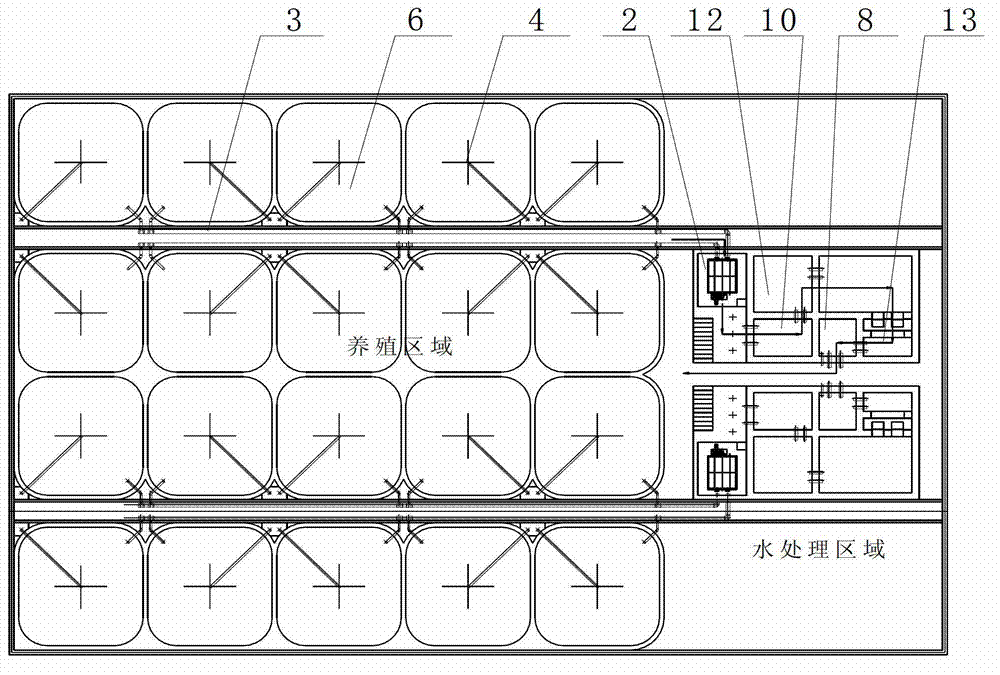

[0060] The algae industrialized recirculating aquaculture system usually includes a breeding area and a water treatment area:

[0061] The aquaculture area includes a plurality of aquaculture fish ponds 6 arranged in a matrix. A single aquaculture fish pond 6 is rectangular, with four corners being inscribed corners. One end is connected to the return channel outside the pool body,

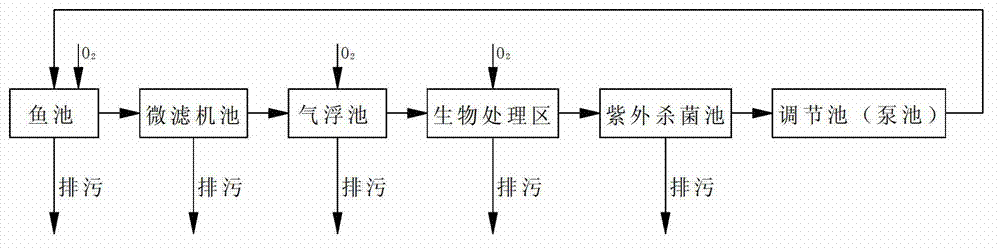

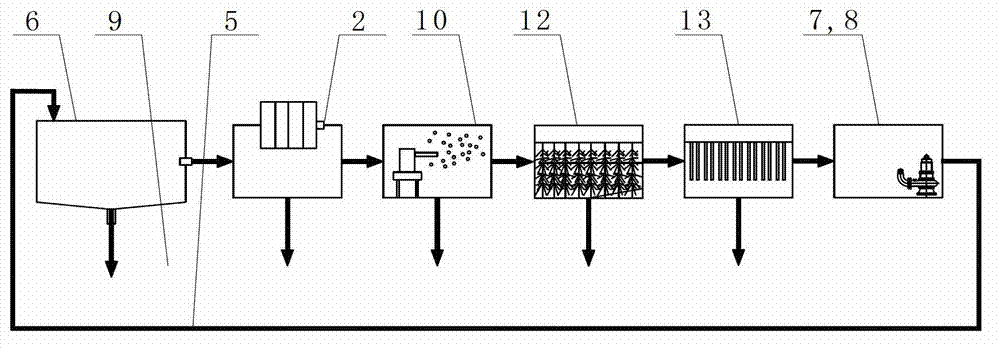

[0062] The water treatment area includes a microfilter pool 2 connected in sequence, an air flotation pool 10, a biological treatment area 12, an ultraviolet sterilization pool 13 and a regulating pool 8, the return channel 3 is connected to the microfilter pool 2, and the water body in the air flotation pool 10 Bubble-guiding baffles are arranged on the surface, one end of the bubble-guiding baffle extends out of the air flotation tank 10, and a bubble discharge well is arranged under the end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com