A burner system and a method for increasing the efficiency of a heat exchanger

一种热交换器、燃烧器的技术,应用在燃烧方法、燃烧器、气体燃料燃烧器等方向,能够解决不是控制爆燃脉冲等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

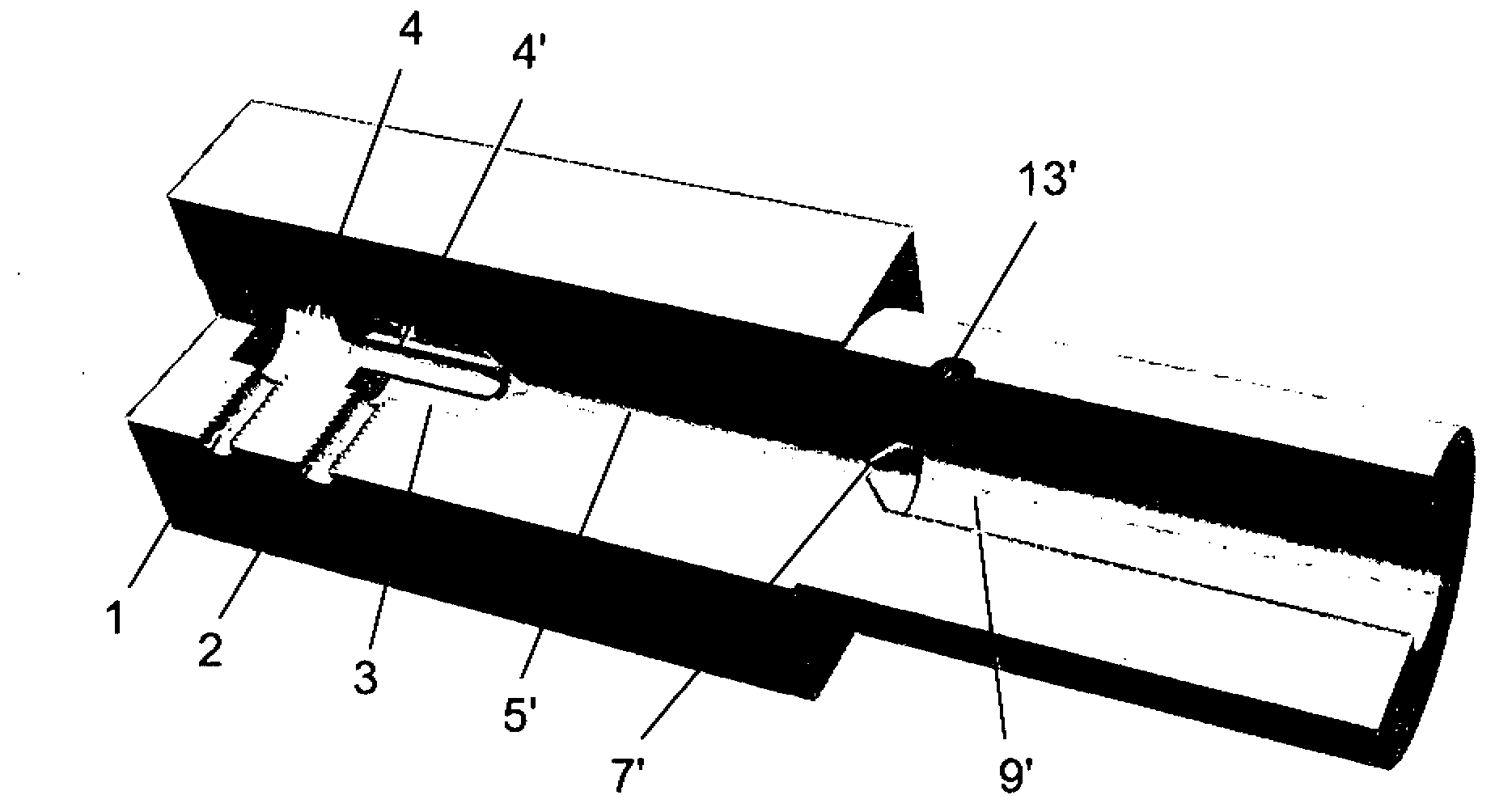

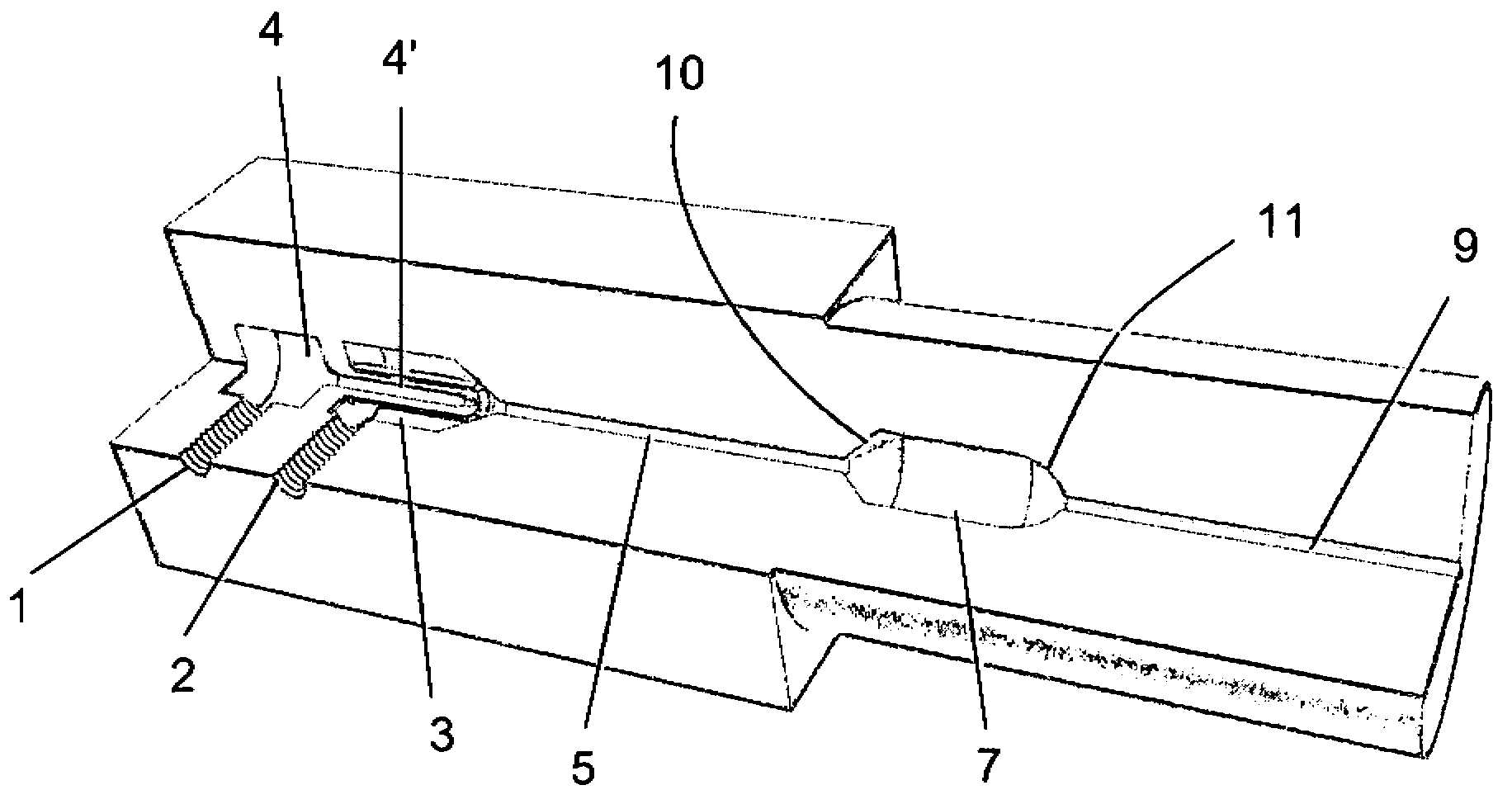

[0062] The present invention relates to a method of burning, consuming or reacting compounds to achieve higher reaction temperatures between two or more compounds such as fuel and air. At the same time, the present invention relates to a method of increasing the efficiency of a heat exchanger or system connected to a burner or other device for heating water, steam or gaseous material with released thermal energy. The invention is primarily intended to improve heat exchangers for steam production, but also for other systems using heat exchangers associated with exothermic reactions to exchange thermal energy from one medium to another.

[0063] The present invention provides a burner system that produces pulsed pressure waves that can be easily used to increase the efficiency of heat exchangers by using controlled continuous pulsed explosions or deflagrations instead of continuous flow, which enables fluids to "heat" at extremely high temperatures. quasi-continuous combustion"....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com