System and method for judging stability of tribology system

A system stability and judging system technology, applied in the testing of measuring devices, instruments, machines/structural components, etc., can solve the problems of monitoring the wear process, inability to extract, and the friction and wear process cannot be carried out continuously, achieving a wide range of applications, Avoid irresistible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention:

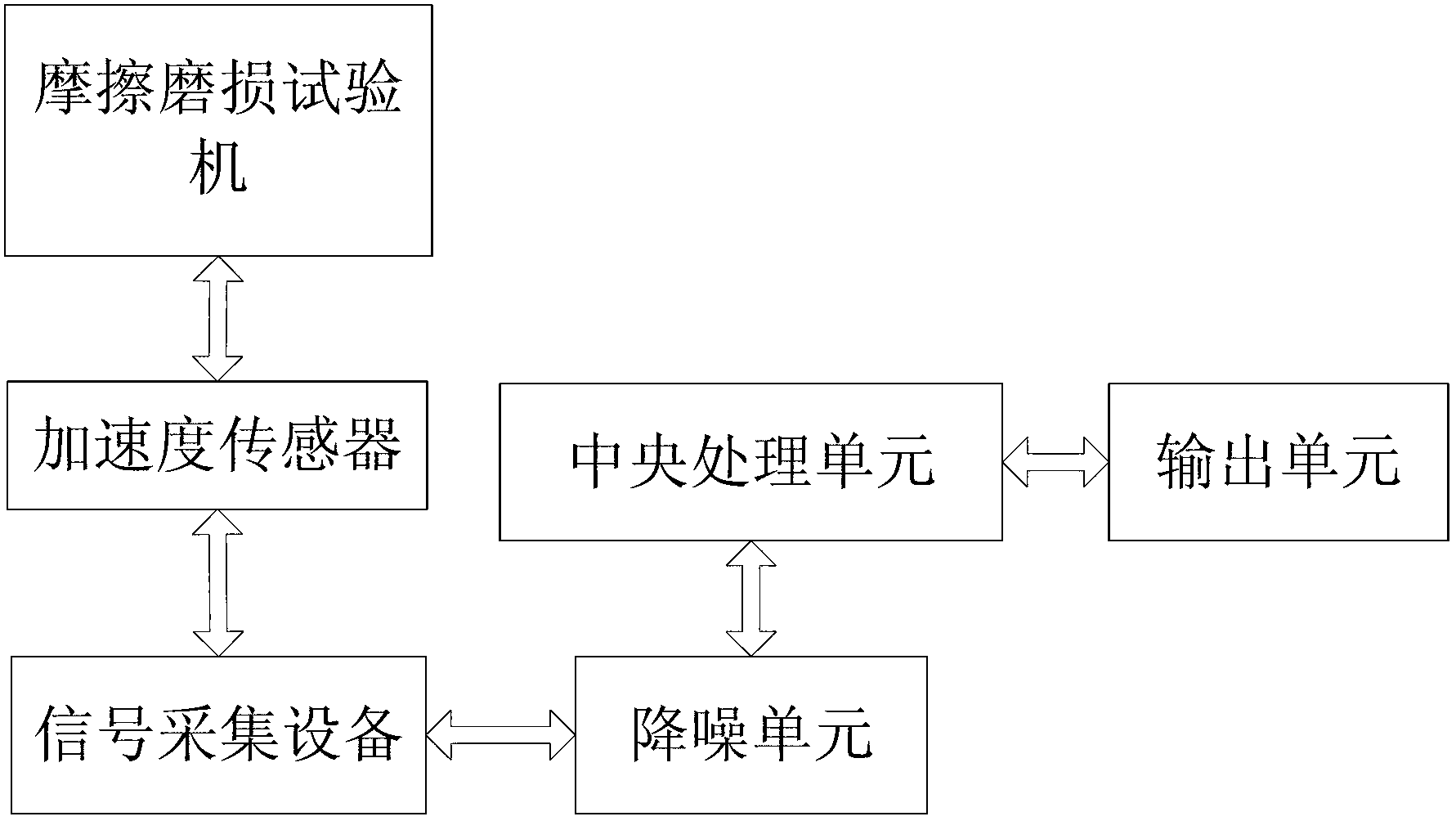

[0026] Such as figure 1 Shown: the tribological system stability testing system, including a friction and wear testing machine, an acceleration sensor, a signal acquisition device, a noise reduction unit, a central processing unit and a display unit electrically connected to each other.

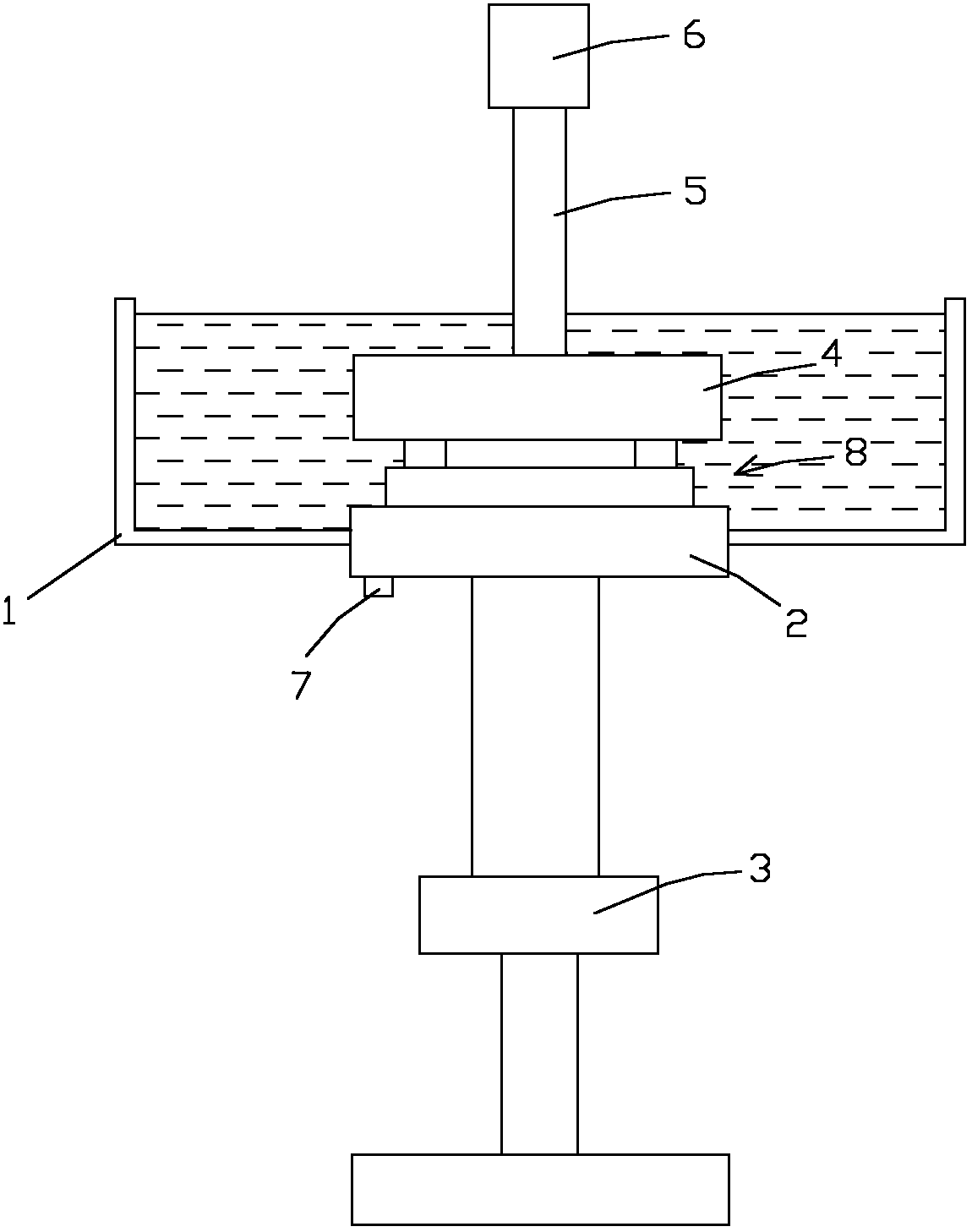

[0027] The friction and wear testing machine adopted in the present invention is a rotating friction and wear testing machine, such as image 3 The main features are: a horizontal tray 2 for carrying the tribological system to be tested, and a vertical support shaft 3 is connected to the bottom of the horizontal tray 2. During the experiment, the support shaft 3 can be a horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com