Hydro-viscous speed regulation device

A fluid-viscous, speed-regulating technology, applied in the direction of fluid clutches, clutches, mechanical equipment, etc., can solve problems such as eccentric wear of friction pairs, achieve the effects of shortening the axial distance, saving costs, and improving the uniformity of the oil film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

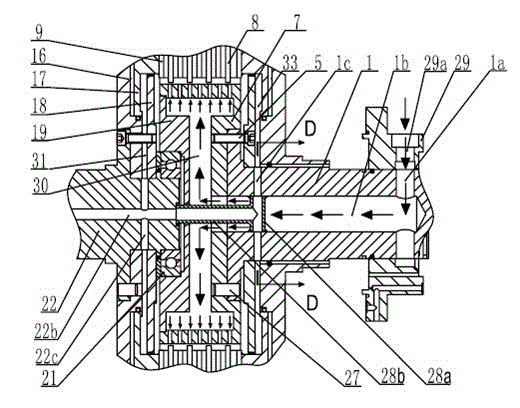

[0037] Further, as the second embodiment of the present invention, the transmission mechanism is the same as that of the first embodiment of the present invention, and the control mechanism still adopts a single piston structure, but the piston cylinder (ie, the first piston cylinder) adopts Figure 8 with Picture 9 The structure shown, thereby obtaining better technical effects. Specifically, such as Figure 8 with Picture 9 As shown, the driven disk 16 and the first piston top disk 18 are respectively fixedly connected to the driven shaft 22, thereby forming a piston cylinder block (that is, the cylinder of the first piston cylinder) between the driven disk 16 and the first piston top disk 18 Body), the first piston 17 is placed in the piston cylinder and partitions the piston cylinder into a first spring displacement cavity 32 and a first working oil cavity 31 that are not connected to each other. Among them, a first spring displacement chamber 32 is formed between the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com